How to make a tool changer move to home

- bevins

-

- Offline

- Platinum Member

-

- Posts: 1942

- Thank you received: 338

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

How is he doing his toolchange now? He said it was working.... I dont understand.

Thanks for taking the time to reply.

The tool changer is on a small Boxford 125 it has been discussed in this post forum.linuxcnc.org/38-general-linuxcnc-q...ved?start=100#188519

Basically we have had to modify the comp (well Aciear did) that was done in the Linuxcnc 2.4-2.6 that would not work with the latest versions of linuxcnc.

The tool changer will now rotate to the correct tool and reverse to lock as commanded with a M6T# now I am trying to get it to move in X and then Z to a safe position to rotate. This is where the TOOL_CHANGE_QUILL_UP = 1 came in, but that will move Z first then X which is wrong for a lathe.

I hope this clears it up a bit.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

Clive!

So remap of M6 is going to be the next adventure.

David you have caught me out in my travels.

There was no home switches on the Boxford so I am fitting them on X and Z they are coming on Wednesday. I have already done the work and wiring as I had PNP ones but needed NPN.

I will read and try and digest your other post in the morning.

Thanks again for the interest.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

Clive!

So remap of M6 is going to be the next adventure.

David you have caught me out in my travels.

There was no home switches on the Boxford so I am fitting them on X and Z they are coming on Wednesday. I have already done the work and wiring as I had PNP ones but needed NPN.

I will read and try and digest your other post in the morning.

Thanks again for the interest.

Ok the first set of sensors never showed up but the second lot did

Now the little lathe homes with X first then Z from with the shared input pin 13 on the P/port all working fine. X and Z are furriest from the chuck when homed.

Now is this what you are suggesting for me to try:-

.

.Seems to me you would need to add this to your INI

REMAP=M6 modalgroup=6 ngc=mychange

Then create a file in your remap folder called mychange.ngc and put this inside:

o<mychange> sub

G53 G0 X0

M66E0L0

G0 Z0

M6 (use built in M6 behavior)

o<mychange> endsub

m2

Something of a crude first idea (I'm tired). But the point is that you might not need to remap the whole toolchange procedure since your tool changer is already working. All you need is to do the moves before it and it looks like there is a nice shortcut for you by being able to call M6 from within its own remap.

By the way: I suggested "M66E0L0" between the moves so the two motions don't get blended.

If so I will try in the morning.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

Seems to me you would need to add this to your INI

REMAP=M6 modalgroup=6 ngc=mychange

Then create a file in your remap folder called mychange.ngc and put this inside:

o<mychange> sub

G53 G0 X0

M66E0L0

G0 Z0

M6 (use built in M6 behavior)

o<mychange> endsub

m2

Z & X farthest from chuck

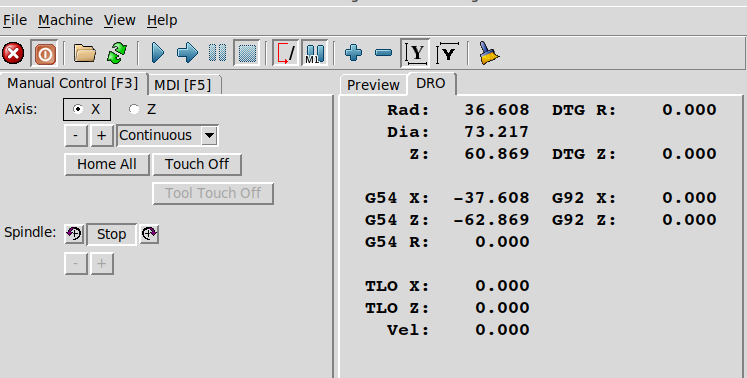

First home machine screenshot

.

.

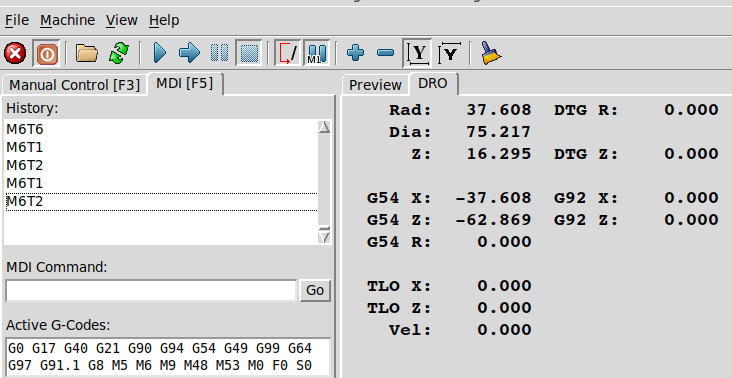

Then MDI m6t2 (You have to inform the gui what tool is in the slot so it knows the tool pocket number)

X went up +ve (ignored soft limit) and Z went towards chuck so aborted

Aborted Screen shot

.

.

Restarted lcnc

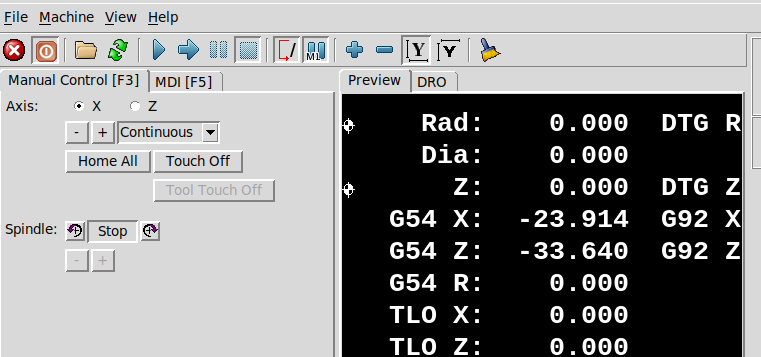

Re-homed then moved x and z nearer the chuck and touched off

touch off screenshot

.

.

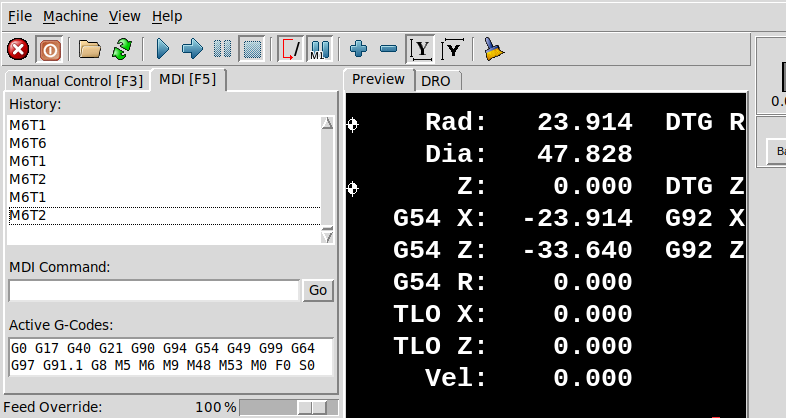

Then MDI m6t2 X went up and hit the switch

Screenshot

.

.

Sorry I could not find a way to rotate. Well I did rotate but it still made it upside down

.

So getting there slowly Thanks for the previous help

Edit: just so we are on the same hymn sheet.

X

MIN_LIMIT = -100

MAX_LIMIT = 1

HOME = -1.0

HOME_OFFSET = 0.0

HOME_OFFSET = 0.0

HOME_SEARCH_VEL = -15

HOME_LATCH_VEL = 1.500000

HOME_SEQUENCE = 0

Z

MIN_LIMIT = -100

MAX_LIMIT = 1

HOME = -2

HOME_OFFSET = 0.0

HOME_SEARCH_VEL = -15

HOME_LATCH_VEL = 1.500000

HOME_SEQUENCE = 1

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4661

- Thank you received: 2078

o<mychange> sub

M73

G90

G53 G0 X0

M66 E0 L0

G53 G0 Z0

M6 (use built in M6 behavior)

o<mychange> endsub

[edit]

The other thing is that you need to make sure it can go to machine zero without activating either the soft limit (needs to be just under 0. I have it at -0.1) or the electrical home switch. I in doubt use G53 G0 X1 and G53 G0 Z1 or -1 whichever is on the good side of your limits.

[2.edit]

You can try the moves in MDI first and once that works build them into your M6 remap

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4661

- Thank you received: 2078

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

So the soft limits should not interfere. How is it working for you using G53 G0 Z0?

edit: Using G53 G0 Z0 it triggers the switch

Ok using G53 G0 Z-1 and G53 G0 X-1 does not hit the switches

I have not tried your new code yet as I have run out of time but I can see the light. Thanks. I will try it in the morning

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

So the soft limits should not interfere. How is it working for you using G53 G0 Z0?

edit: Using G53 G0 Z0 it triggers the switch

Ok using G53 G0 Z-1 and G53 G0 X-1 does not hit the switches

I have not tried your new code yet as I have run out of time but I can see the light. Thanks. I will try it in the morning

Ok Seems to work as expected. I think I would like the toolchanger ngc to go in the boxford config folder instead of the ngc folder How would I write the path in the ini file.? It is like this now REMAP=M6 modalgroup=6 ngc=toolchange

I stuck a M3 and M4 tin the code to make sure the spindle was working correct.

.

.

The next bit now is to get the spindle speed display working correct with the near component . I have just forced it with setp to true

Also do I really need the B encoder signal if it is not going to be used for ridged tapping. The spindle has to be able to do an M3 and M4 depending what tool is being used.

But I would like to free up an input pin so as to make the homing safer. As I have noticed if the Z sensor is triggered before homing then the X will start moving down first. This is a problem with sharing home switches on one input. I know it might never happen BUT!! Mr. Murphy might call.

Thanks for your continued help. I have learnt a lot from you.

Please Log in or Create an account to join the conversation.