7i96 configuration Tool and Gantry XYZ Machines

- SSIRon

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 4

09 Jan 2022 06:00 #231219

by SSIRon

Replied by SSIRon on topic 7i96 configuration Tool and Gantry XYZ Machines

RNJFAB

i did try and got errors but i am going to try this again tomorrow.

i did try and got errors but i am going to try this again tomorrow.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

09 Jan 2022 23:45 #231268

by BigJohnT

Replied by BigJohnT on topic 7i96 configuration Tool and Gantry XYZ Machines

I'll look at the files in the morning.

JT

JT

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

09 Jan 2022 23:49 #231269

by BigJohnT

Replied by BigJohnT on topic 7i96 configuration Tool and Gantry XYZ Machines

I did a quick check on the ini file with the tool and it does have an issue with reloading Joint 1

JT

JT

Please Log in or Create an account to join the conversation.

- SSIRon

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 4

10 Jan 2022 00:30 #231272

by SSIRon

Replied by SSIRon on topic 7i96 configuration Tool and Gantry XYZ Machines

John - i did get it to run from the pncconf wizard. I must have made an error the first time around but it seems to be on track now. If you would like i can test the tool once you are ready.

I do wish there was a way to jog x and x2 with out homing. I know there is resistance to this but i can do it mach 3 and i can do it on my waterjet (with an override) and i find it helpful to move a machine with out homing. as long as both joints are moving.

I do wish there was a way to jog x and x2 with out homing. I know there is resistance to this but i can do it mach 3 and i can do it on my waterjet (with an override) and i find it helpful to move a machine with out homing. as long as both joints are moving.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

10 Jan 2022 00:42 - 10 Jan 2022 00:43 #231274

by RNJFAB

Replied by RNJFAB on topic 7i96 configuration Tool and Gantry XYZ Machines

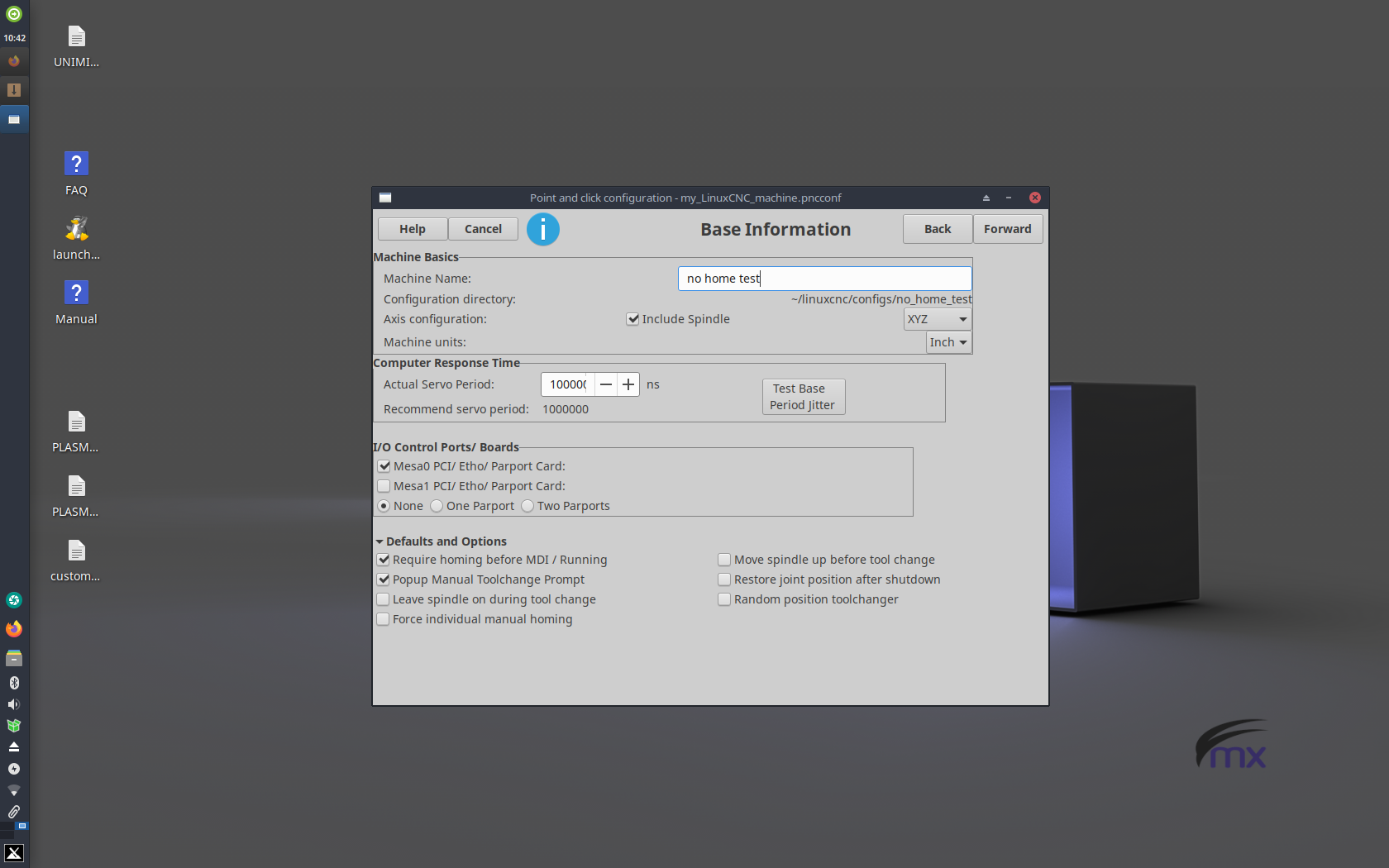

I thought there was a setting (tick Box) to ask if homing was required before moving.

There is in the Pncconfig.

I can see it would be handy when testing axis before you have a working machine. However, once a working machine is in place, i can't imagine not homing everything to ensure you have a correct 0 and square gantry before starting a job.

There is in the Pncconfig.

I can see it would be handy when testing axis before you have a working machine. However, once a working machine is in place, i can't imagine not homing everything to ensure you have a correct 0 and square gantry before starting a job.

Attachments:

Last edit: 10 Jan 2022 00:43 by RNJFAB.

Please Log in or Create an account to join the conversation.

- SSIRon

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 4

10 Jan 2022 01:47 #231276

by SSIRon

Replied by SSIRon on topic 7i96 configuration Tool and Gantry XYZ Machines

RNJFab thanks for all your help. i believe that setting does not work with a gantry machine, i will have to try it again to be sure. I do move my machines without homing. I will home before starting a job but if i load materials or doing maintenance. there are circumstances when i just need to jog machine short distance or to thee oposite end of the table and i do not want any other movement.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

10 Jan 2022 06:55 #231289

by RNJFAB

Replied by RNJFAB on topic 7i96 configuration Tool and Gantry XYZ Machines

You could always home to the back left/right to make it easier to load a sheet. I always home to the front left as it's close to where i park when i shut the machine down, then i have buttons to send it to the back left to load a sheet.

I didn't think there would be much difference between an XXYZ machine or a XYYZ machine. still running on axis with 2 motors.

I didn't think there would be much difference between an XXYZ machine or a XYYZ machine. still running on axis with 2 motors.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

10 Jan 2022 23:09 - 10 Jan 2022 23:11 #231361

by BigJohnT

Replied by BigJohnT on topic 7i96 configuration Tool and Gantry XYZ Machines

I can add no force homing, it was an oversight by me. Thanks for the report.

I didn't get a chance to look at the tool this morning busy diagnosing a faulty chicken door in Coop Uno.

JT

I didn't get a chance to look at the tool this morning busy diagnosing a faulty chicken door in Coop Uno.

JT

Last edit: 10 Jan 2022 23:11 by BigJohnT.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- SSIRon

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 4

11 Jan 2022 05:14 #231398

by SSIRon

Replied by SSIRon on topic 7i96 configuration Tool and Gantry XYZ Machines

BigJohnT .. I took everything out to shop and did the swap. My router is up running. a little tweaking tomorrow and i think i will be back in operation. I BTW .. i use commercial damper actuator for my chicken door actuators. lasts for decades.

Rnjfab --- we are good it is running. you were a big help .. thank you

Rnjfab --- we are good it is running. you were a big help .. thank you

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

11 Jan 2022 14:10 #231445

by BigJohnT

Replied by BigJohnT on topic 7i96 configuration Tool and Gantry XYZ Machines

I added the missing homing items and no force homing on the options page and uploaded a new deb. If you can test it that would be great.

I added a DS18B20 temperature probe to the Raspberry Pi and somehow pulled out the wire for the up relay. My doors use a gear motor with a spool and paracord to raise and lower the door. This way it can come down on top of a stubborn hen without hurting her.

JT

I added a DS18B20 temperature probe to the Raspberry Pi and somehow pulled out the wire for the up relay. My doors use a gear motor with a spool and paracord to raise and lower the door. This way it can come down on top of a stubborn hen without hurting her.

JT

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.162 seconds