spindle with encoder

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 610

- Thank you received: 17

13 Apr 2025 23:23 #326237

by vre

spindle with encoder was created by vre

I have a spindle that has motor pulley belt pulley

after has a geartrain with 2 positions-speeds.

I want to mount encoder to second pulley shaft before geartrain.

Iam confused how to set ini file values

max_speed min_speed encoder_scale output_scale etc

after has a geartrain with 2 positions-speeds.

I want to mount encoder to second pulley shaft before geartrain.

Iam confused how to set ini file values

max_speed min_speed encoder_scale output_scale etc

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 610

- Thank you received: 17

14 Apr 2025 21:47 - 14 Apr 2025 21:49 #326320

by vre

Replied by vre on topic spindle with encoder

Motor has inverter that controls rpm of motor via -10V+10V analog signal (mesa 7i33 card).

No can't remove the geartrain. I need encoder for rigid taping.

My problem is how to configure because it is not easy to mount encoder on spindle

shaft must mount it before geartrain of spindle so before 2 selectable speeds reduction is done.

So the problem is that motor has X rpm, encoder has a*X rpm and spindle has b*X rpm or c*X rpm.

What must put in ini file spindle section ?

No can't remove the geartrain. I need encoder for rigid taping.

My problem is how to configure because it is not easy to mount encoder on spindle

shaft must mount it before geartrain of spindle so before 2 selectable speeds reduction is done.

So the problem is that motor has X rpm, encoder has a*X rpm and spindle has b*X rpm or c*X rpm.

What must put in ini file spindle section ?

MAX_OUTPUT = ?

ENCODER_SCALE = ?

OUTPUT_SCALE = ?

OUTPUT_MIN_LIMIT = ?

OUTPUT_MAX_LIMIT = ?

Last edit: 14 Apr 2025 21:49 by vre.

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

14 Apr 2025 22:01 #326321

by JohnnyCNC

Replied by JohnnyCNC on topic spindle with encoder

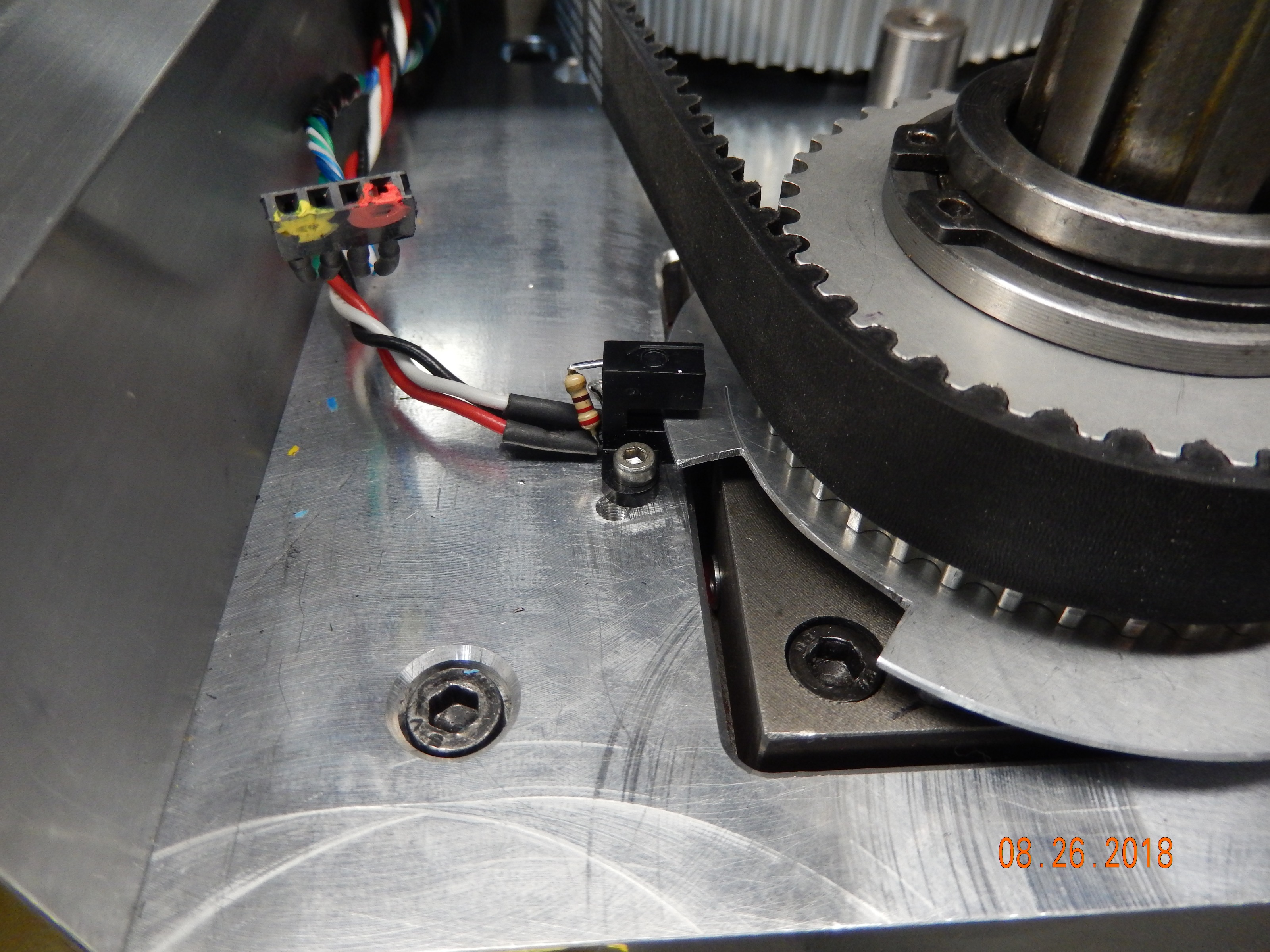

Attachments:

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 610

- Thank you received: 17

14 Apr 2025 23:18 #326324

by vre

Replied by vre on topic spindle with encoder

I will do rigid taping in slow gears speed..

For 2 speeds selection i will use this hal file

and this function

How can set also encoder for rigid tapping ?

For 2 speeds selection i will use this hal file

#M64 and M65 digital outputs

net sp-shift-high motion.digital-out-12 mesacard_pin

net sp-shift-low motion.digital-out-13 mesacard_pin

#M66 Digital Inputs

net spindle-stoped motion.digital-in-09 mesacard_pin

net sp-is-high motion.digital-in-12 mesacard_pin

net sp-is-low motion.digital-in-13 mesacard_pinand this function

;Erik Salo January 2018

;Okada VM500 Spindle Gearchange program LinuxCNC

;Two speed gearbox. Selects proper range for commanded speed

;Stops spindle prior to gear change

;Special handling for zero, don;t shift down for zero command if in high speed

;Two sensors, one for high and one for low

;Two hydraulic solenoids high and low, turnsoff unselected solenoid

o<setspeed> sub

o300 IF [#<speed> GT 1250]

;Check to see if speed selected is too high

o010 IF [#<speed> GT 5001]

(abort, Speed exceeds rated rpm)

o010 ENDIF

M66 P12 ;Check if High Gear = True

o301 if [#5399 GT 0]

M66 P13 ;Make sure Low Gear = False

o302 if [#5399 GT 0]

(abort, spindle still in low gear)

o302 endif

S#<speed> ;Set spindle speed with no scaling factor

o301 endif

M66 P13 ;Check if Low Gear = True

o305 if [#5399 GT 0]

M66 P12 ;Make sure High Gear = False

o306 if (#5399 GT 0]

(abort, spindle still in high gear)

o306 endif

S0 ; Stop spindle

M66 P9 L3 Q4 ;Check for spindle stopped - wait up to 4 seconds for digital input 9 to turn on

o307 if [#5399 LT 0]

(abort, spindle not stopped)

o307 endif

M65 P13 ; Turn off low gear shift solenoid

M64 P12 ; Turn on high gear shift solenoid

M66 P13 L4 Q4 ;Wait for Low Gear = False

o308 if [#5399 GT 0]

(abort, spindle still in low gear)

o308 endif

M66 P12 L3 Q4 ;Wait for High Gear = True

o310 if [#5399 LT 0]

(abort, spindle not in high gear)

o310 endif

S#<speed> ;Set spindle speed with no scaling factor

o305 endif

o300 ENDIF

;Low Gear Section

o400 IF [#<speed> LT 1250.1] ;Check if requested speed is less than 1250

o410 IF [4<speed> GT 0.1] Check to see if requested speed is greater than 0.1

M66 P13 ;Check if Low Gear = True

o420 if (#5399 GT 0]

M66 P12 ;Make sure High Gear = False

o421 if [#5399 GT 0]

(abort, spindle still in high gear)

o421 endif

S[#<speed>*2.56] ;Set spindle speed with 4x scaling factor

o420 endif

M66 P12 ;Check if High Gear = True

o430 if [#5399 GT 0]

M66 P13 ;Make sure Low Gear = False

o431 if (#5399 GT 0]

(abort, spindle still in high gear)

o431 endif

S0 ; Stop spindle

M66 P9 L3 Q5 ;Check for spindle stopped

o432 if [#5399 LT 0]

(abort, spindle not stopped)

o432 endif

M65 P12 ; Turn off high gear shift solenoid

M64 P13 ; Turn on low gear shift solenoid

M66 P12 L4 Q4 ;Wait for High Gear = False

o433 if (#5399 GT 0]

(abort, spindle still in low gear)

o433 endif

M66 P13 L3 Q4 ;Wait for Low Gear = True

o434 if (#5399 LT 0]

(abort, spindle not in high gear)

o434 endif

S[#<speed>*2.56] ;Set spindle speed with 4x scaling factor

o430 endif

o410 endif

o450 IF [#<speed> EQ 0]

S0

; Set spindle speed to zero

o450 ENDIF

o400 ENDIF

o<setspeed> endsub [1]How can set also encoder for rigid tapping ?

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

15 Apr 2025 01:14 #326329

by JohnnyCNC

Replied by JohnnyCNC on topic spindle with encoder

My top spindle speed is 5400 RPM and that plate is .032" aluminum. If it does cause vibrations, they are too small for me to notice.

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 610

- Thank you received: 17

15 Apr 2025 18:31 #326397

by vre

Replied by vre on topic spindle with encoder

more notches are better but how can i set encoder

if encoder can only positioned before geartrain ?

if encoder can only positioned before geartrain ?

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

15 Apr 2025 22:14 #326413

by JohnnyCNC

Replied by JohnnyCNC on topic spindle with encoder

Hold on a second. I lied. Not intentionally. My spindle motor is a DYN4 servo motor geared 1:1.8 and it has a simulated encoder signal generated by the servo driver. That is the signal I am using for the coordination for rigid tapping. The sensor on the slotted plate it just for measuring RPM.

It's been a few years since I set this up and when you mentioned more slots I thought "I knew that, why didn't I do that?" Then I looked deeper and remembered how it really works.

To actually do this with a slotted plate and sensors you would want more slots and two sensors. Read up on how quadrature encoders work.

As long as you know the ratio between the spindle and encoder you can make almost any arrangement work.

These are my .ini settings.

[SPINDLE_0]

P = 2.0

I = 4.0

D = 0.0

FF0 = 1.08

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

OUTPUT_MIN_LIMIT = -5400.0

OUTPUT_MAX_LIMIT = 5400.0

OUTPUT_SCALE = -10800

ENCODER_SCALE = 4551.111111

#((2048 * 4) / 1.8) = 4551.111111

#The maximum spindle speed (in rpm)

MAX_FORWARD_VELOCITY = 5400

#The minimum spindle speed (in rpm)

MIN_FORWARD_VELOCITY = 50

#This setting will default to MAX_FORWARD_VELOCITY if omitted.

MAX_REVERSE_VELOCITY = 5400

#The minimum spindle speed (in rpm)default to MIN_FORWARD_VELOCITY if omitted.

MIN_REVERSE_VELOCITY = 50

Sorry for the confusion. I hope this helps.

It's been a few years since I set this up and when you mentioned more slots I thought "I knew that, why didn't I do that?" Then I looked deeper and remembered how it really works.

To actually do this with a slotted plate and sensors you would want more slots and two sensors. Read up on how quadrature encoders work.

As long as you know the ratio between the spindle and encoder you can make almost any arrangement work.

These are my .ini settings.

[SPINDLE_0]

P = 2.0

I = 4.0

D = 0.0

FF0 = 1.08

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

OUTPUT_MIN_LIMIT = -5400.0

OUTPUT_MAX_LIMIT = 5400.0

OUTPUT_SCALE = -10800

ENCODER_SCALE = 4551.111111

#((2048 * 4) / 1.8) = 4551.111111

#The maximum spindle speed (in rpm)

MAX_FORWARD_VELOCITY = 5400

#The minimum spindle speed (in rpm)

MIN_FORWARD_VELOCITY = 50

#This setting will default to MAX_FORWARD_VELOCITY if omitted.

MAX_REVERSE_VELOCITY = 5400

#The minimum spindle speed (in rpm)default to MIN_FORWARD_VELOCITY if omitted.

MIN_REVERSE_VELOCITY = 50

Sorry for the confusion. I hope this helps.

The following user(s) said Thank You: vre

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 610

- Thank you received: 17

15 Apr 2025 23:42 #326415

by vre

Replied by vre on topic spindle with encoder

This helps..

What is OUTPUT_SCALE = -10800 ?

This config is for fixed motor:spindle transmition ratio.

I have 2 selectable speeds after encoder-motor

These 2 speeds are selected by hydraulic electrovalve that switches gears

position 1 max rpm is 760rpm and position 2 max rpm 3060

What is OUTPUT_SCALE = -10800 ?

This config is for fixed motor:spindle transmition ratio.

I have 2 selectable speeds after encoder-motor

These 2 speeds are selected by hydraulic electrovalve that switches gears

position 1 max rpm is 760rpm and position 2 max rpm 3060

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

16 Apr 2025 23:21 #326495

by JohnnyCNC

Replied by JohnnyCNC on topic spindle with encoder

I'm not really sure exactly what is does, but this is where it is used in my hal file.

It looks like it is set to -10800 because 5400 to -5400 is -10800.

# ---Analog output signals/setup---

setp hm2_7i76e.0.7i83.0.1.analogout5-scalemax [SPINDLE_0]OUTPUT_SCALE

setp hm2_7i76e.0.7i83.0.1.analogout5-minlim [SPINDLE_0]OUTPUT_MIN_LIMIT

setp hm2_7i76e.0.7i83.0.1.analogout5-maxlim [SPINDLE_0]OUTPUT_MAX_LIMIT

net spindle-output => hm2_7i76e.0.7i83.0.1.analogout5

It looks like it is set to -10800 because 5400 to -5400 is -10800.

# ---Analog output signals/setup---

setp hm2_7i76e.0.7i83.0.1.analogout5-scalemax [SPINDLE_0]OUTPUT_SCALE

setp hm2_7i76e.0.7i83.0.1.analogout5-minlim [SPINDLE_0]OUTPUT_MIN_LIMIT

setp hm2_7i76e.0.7i83.0.1.analogout5-maxlim [SPINDLE_0]OUTPUT_MAX_LIMIT

net spindle-output => hm2_7i76e.0.7i83.0.1.analogout5

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

18 Apr 2025 10:10 #326585

by andypugh

Replied by andypugh on topic spindle with encoder

Note that unless the index pulse is from the spindle shaft, or the gear ratio is exactly 1:1, you can't peck-tap with the encoder on the motor shaft. This probably isn't a problem in most cases, but is worth being aware of.

Please Log in or Create an account to join the conversation.

Time to create page: 0.320 seconds