Search Results (Searched for: estop_latch)

- tommylight

14 Feb 2025 19:37

Replied by tommylight on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- rodw

16 Jan 2025 07:56 - 16 Jan 2025 07:57

Replied by rodw on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

Well, looks like you have

so you should remove or comment out this line

net remote-estop estop-latch.0.fault-in <= hm2_[HOSTMOT2](7i96S).0.gpio.04.in_not

and replace it with this

# --- ESTOP-EXT ---

net estop-ext <= hm2_7i96s.0.inm.00.input-03so you should remove or comment out this line

net remote-estop estop-latch.0.fault-in <= hm2_[HOSTMOT2](7i96S).0.gpio.04.in_not

and replace it with this

net estop-ext => estop-latch.0.fault-in- notJamesLee

- notJamesLee

16 Jan 2025 04:06

Replied by notJamesLee on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

okay so i went to that linked tutorial I commented out the existing estop loop and ended up actually testing code from the last entry on the first page (copied and pasted below) but modified with my pin for the estop.

Code i am using:

Now i am getting a similar error where it it thinks pins are double assigned. Should I have commented out other pin assignments? Or could i not be assinging the pin corectly?

error message:

Code i am using:

loadrt estop_latch addf estop-latch.0 servo-thread net estop-loopout iocontrol.0.emc-enable-in <= estop-latch.0.ok-out net estop-loopin iocontrol.0.user-enable-out => estop-latch.0.ok-in net estop-reset iocontrol.0.user-request-enable => estop-latch.0.reset net remote-estop estop-latch.0.fault-in <= hm2_[HOSTMOT2](7i96s).0.gpio.040.in_notNow i am getting a similar error where it it thinks pins are double assigned. Should I have commented out other pin assignments? Or could i not be assinging the pin corectly?

error message:

.hal:258: Signal 'a-pos-fb' can not add OUT pin 'hm2_7i96s.0.encoder.00.position'. It already has OUT pin ' hm2_7i96s.0.stepgen.03.position-fb' 2034- notJamesLee

- notJamesLee

15 Jan 2025 06:10 - 15 Jan 2025 16:50

Replied by notJamesLee on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

Thanks for the reply.

I added the code in the linked tutorial, does that bind it to a specific pin? It looks like the last line (below) assigns it to pin10? should I change this to the pin i have mine currently wired to?The video so far is very informative and ill use it as a reference when im out working on it tomorrow but no info on how to daisy chain them. I assume since they're NC i can just wire them in series to one input pin? or is that a no-no?

I added the code in the linked tutorial, does that bind it to a specific pin? It looks like the last line (below) assigns it to pin10? should I change this to the pin i have mine currently wired to?

net remote-estop estop-latch.0.fault-in <= parport.0.pin-in10-not- rodw

15 Jan 2025 03:00

Replied by rodw on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

The better way is to use estop_latch. There is a tutorial here

forum.linuxcnc.org/47-hal-examples/25861-external-e-stop

it is possible to daisy chain multiple estop_latch components together but its not documented anywhere

I found drawing a diagram of the connections helps to work it out.

Here is video which may be useful

forum.linuxcnc.org/47-hal-examples/25861-external-e-stop

it is possible to daisy chain multiple estop_latch components together but its not documented anywhere

I found drawing a diagram of the connections helps to work it out.

Here is video which may be useful

- Benb

29 Dec 2024 04:18

Replied by Benb on topic Physical safety relay and software estop latch working together?

Physical safety relay and software estop latch working together?

Category: HAL

Hi Thomas,

For the block diagram conversion to Hal netlisting I use Eagle2hal its documentated in lthe inuxcnc wiki (old but works for me). However if I had to start again I would learn Ed Nisley's Kicad to HAL the source code is in Python also the Kicad people are planning to release a schematic API in their next release this would make it easy to make run time changes to the schematic capture and animate the schematic with realtime values.

gist.github.com/ednisley/cd69ad5a899226067d7a4a92c2114568

For the block diagram conversion to Hal netlisting I use Eagle2hal its documentated in lthe inuxcnc wiki (old but works for me). However if I had to start again I would learn Ed Nisley's Kicad to HAL the source code is in Python also the Kicad people are planning to release a schematic API in their next release this would make it easy to make run time changes to the schematic capture and animate the schematic with realtime values.

gist.github.com/ednisley/cd69ad5a899226067d7a4a92c2114568

- thomaseg

- thomaseg

28 Dec 2024 09:19

I'm not 100% sure the above diagram will work exactly like this with my setup, however your input sparked an idea to solve my "circular dependency" problem between the software and hardware latches: I need to use a "oneshot"-component to connect the two latches instead of connecting them directly(and thereby creating the problematic circular dependency). Sounds obvious now, not sure why i didn't see that option the other day. So thanks for the input, i think i have a viable way to solve this now!

Thanks!

Replied by thomaseg on topic Physical safety relay and software estop latch working together?

Physical safety relay and software estop latch working together?

Category: HAL

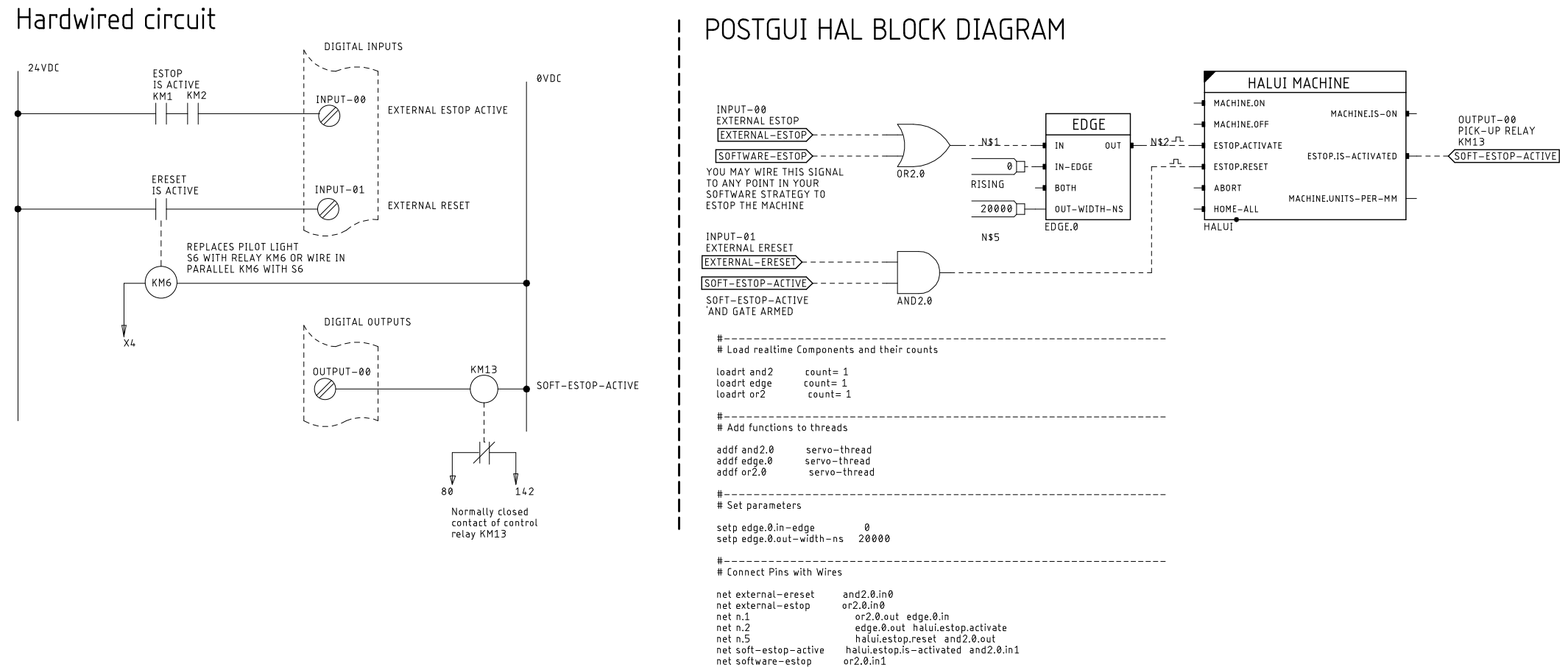

I like your diagrams, what do you use to make them?The hardwired diagram shows two normally open contacts in series KM1 AND KM2 indicating that the Estop is active. The rest of the circuit is similar to what you had in mind. Please do not add a screen (UI) estop or reset buttons; make it a habit to only use the external hardwired estop and reset push buttons otherwise you defeat the use of a safety system. The hal block diagram I use it to generate the hal file but it might help you understand what the hal net file does.

I'm not 100% sure the above diagram will work exactly like this with my setup, however your input sparked an idea to solve my "circular dependency" problem between the software and hardware latches: I need to use a "oneshot"-component to connect the two latches instead of connecting them directly(and thereby creating the problematic circular dependency). Sounds obvious now, not sure why i didn't see that option the other day. So thanks for the input, i think i have a viable way to solve this now!

Thanks! I couldn't wrap my head around this at first, but i think i got the gist of it now. I'll try to implement this short pulse and post the solution here for future reference.rodw post=317388 userid=20660

iocontrol.0.user-request-enable can be used as an estop reset signal (eg in place of S6). A short pulse is sent on this output for this purpose. I chose to just stick with the external reset button and connect to iocontrol.0.emc-enable-in, I used a relay on your S6 circuit to do this

Thanks!

- Benb

27 Dec 2024 01:10

Replied by Benb on topic Physical safety relay and software estop latch working together?

Physical safety relay and software estop latch working together?

Category: HAL

The hardwired diagram shows two normally open contacts in series KM1 AND KM2 indicating that the Estop is active. The rest of the circuit is similar to what you had in mind. Please do not add a screen (UI) estop or reset buttons; make it a habit to only use the external hardwired estop and reset push buttons otherwise you defeat the use of a safety system. The hal block diagram I use it to generate the hal file but it might help you understand what the hal net file does.

#

# Load realtime Components and their counts

loadrt and2 count= 1

loadrt edge count= 1

loadrt or2 count= 1

#

# Add functions to threads

addf and2.0 servo-thread

addf or2.0 servo-thread

addf edge.0 servo-thread

#

# Set parameters

setp edge.0.in-edge 0

setp edge.0.out-width-ns 20000

#

# Connect Pins with Wires

net external-ereset and2.0.in0

net external-estop or2.0.in0

net n.1 or2.0.out edge.0.in

net n.2 edge.0.out halui.estop.activate

net n.5 halui.estop.reset and2.0.out

net soft-estop-active halui.estop.is-activated and2.0.in1

net software-estop or2.0.in1

#

# Load realtime Components and their counts

loadrt and2 count= 1

loadrt edge count= 1

loadrt or2 count= 1

#

# Add functions to threads

addf and2.0 servo-thread

addf or2.0 servo-thread

addf edge.0 servo-thread

#

# Set parameters

setp edge.0.in-edge 0

setp edge.0.out-width-ns 20000

#

# Connect Pins with Wires

net external-ereset and2.0.in0

net external-estop or2.0.in0

net n.1 or2.0.out edge.0.in

net n.2 edge.0.out halui.estop.activate

net n.5 halui.estop.reset and2.0.out

net soft-estop-active halui.estop.is-activated and2.0.in1

net software-estop or2.0.in1

- rodw

26 Dec 2024 05:22

Replied by rodw on topic Physical safety relay and software estop latch working together?

Physical safety relay and software estop latch working together?

Category: HAL

iocontrol.0.user-request-enable can be used as an estop reset signal (eg in place of S6). A short pulse is sent on this output for this purpose. I chose to just stick with the external reset button and connect to iocontrol.0.emc-enable-in, I used a relay on your S6 circuit to do this

If you want an internal estop and an external estop, multiple instances of estop-latch component should let you do this.

If you want an internal estop and an external estop, multiple instances of estop-latch component should let you do this.

- thomaseg

- thomaseg

25 Dec 2024 21:44 - 25 Dec 2024 21:48

Physical safety relay and software estop latch working together? was created by thomaseg

Physical safety relay and software estop latch working together?

Category: HAL

Hi,

I've been spending the last couple of days trying to figure out how to make the "software estop" work together with my safety relay. But i'm going in circles and i need a kick from someone, maybe you?

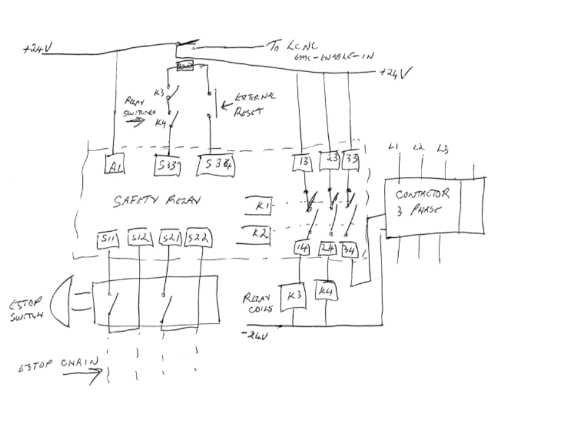

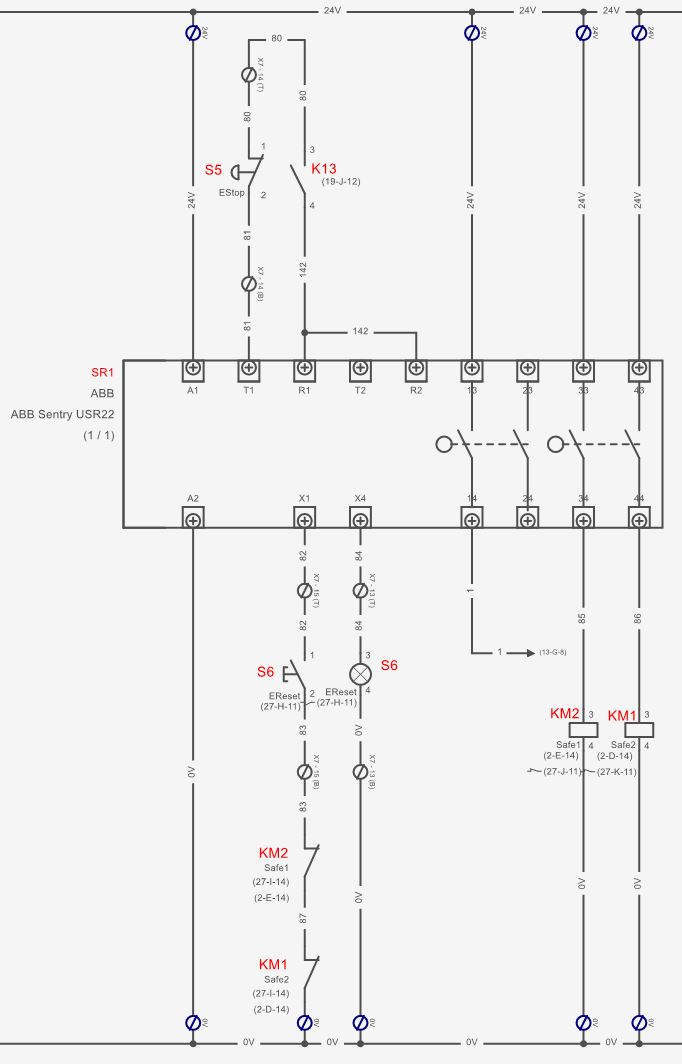

First off, i have this physical circuit to handle the emergency stop logic in hardware:

...the idea is that estop should work without any software involvement. And everything should be as redundant as could be. I have dual (safety) contactors(KM1 + KM2) that cuts power to all drives and at the same time prevents resetting the estop-circuit in cause of failure. I have a proper estop-button(it's redundant contacts, but only shown as one here in S5). On top of that i have added an inline relay, K13, which can be triggered by software, aswell as the wire "1" which goes to an input in LinuxCNC in order to tell it the state of the safety relay. There is a short delay(~0,5sec) between the two sets of relays in the safety relay, so ideally the signal to LinuxCNC should be able to tell the servos to emergency stop just before the power is killed.

So far, so good. Everything works just like i want it. The latching works excellent and the signals to and from LinuxCNC also works as expected....

However, i'm totally going in circles when i try to add an estop latch inside LinuxCNC to work in conjunction with the hardware safety relay. I took inspiration from a thread from the user Unlogic who seem to have it working. But i end up having a latch #1 that depends on latch #2 that depends on latch #1 again....ehh... so currently i'm just having the inputs tied into LinuxCNC like this:

..this "sorta works" and prevents anything powering on before LinuxCNC has booted properly. However the UI experience is kinda bad as i have to press a button extra and there is not really any feedback to the user

SO, the question: Has anyone got a combination of a physical safetyrelay and an estop latch to work "like it should"? I'd be very interested in seeing how others have solved this issue...

/Thomas

I've been spending the last couple of days trying to figure out how to make the "software estop" work together with my safety relay. But i'm going in circles and i need a kick from someone, maybe you?

First off, i have this physical circuit to handle the emergency stop logic in hardware:

...the idea is that estop should work without any software involvement. And everything should be as redundant as could be. I have dual (safety) contactors(KM1 + KM2) that cuts power to all drives and at the same time prevents resetting the estop-circuit in cause of failure. I have a proper estop-button(it's redundant contacts, but only shown as one here in S5). On top of that i have added an inline relay, K13, which can be triggered by software, aswell as the wire "1" which goes to an input in LinuxCNC in order to tell it the state of the safety relay. There is a short delay(~0,5sec) between the two sets of relays in the safety relay, so ideally the signal to LinuxCNC should be able to tell the servos to emergency stop just before the power is killed.

So far, so good. Everything works just like i want it. The latching works excellent and the signals to and from LinuxCNC also works as expected....

However, i'm totally going in circles when i try to add an estop latch inside LinuxCNC to work in conjunction with the hardware safety relay. I took inspiration from a thread from the user Unlogic who seem to have it working. But i end up having a latch #1 that depends on latch #2 that depends on latch #1 again....ehh... so currently i'm just having the inputs tied into LinuxCNC like this:

net estop-loopout iocontrol.0.emc-enable-in <= lcec.0.DI1.din-0 # This is the signal from wire "1"

net estop-relay iocontrol.0.user-enable-out => lcec.0.DO1.dout-3 # This is relay K13SO, the question: Has anyone got a combination of a physical safetyrelay and an estop latch to work "like it should"? I'd be very interested in seeing how others have solved this issue...

/Thomas

- Sternfox

- Sternfox

24 Dec 2024 18:25

Replied by Sternfox on topic Timed delay

Timed delay

Category: Advanced Configuration

Thanks for the code, im getting this error on startup ./main.hal:239: Pin 'xor.0.in0' does not exist

here is my hal file

# This file was created with the Mesa Configuration Tool on Nov 26 2024 15:50:59

# If you make changes to this file DO NOT run the configuration tool again!

# This file will be replaced with a new file if you do!

# kinematics

loadrt [KINS](KINEMATICS)

# motion controller

loadrt [EMCMOT](EMCMOT) servo_period_nsec=[EMCMOT](SERVO_PERIOD) num_joints=[KINS]JOINTS num_dio=30 num_aio=30

# hostmot2 driver

loadrt hostmot2

loadrt [HM2](DRIVER) board_ip=[HM2](ADDRESS) config="sserial_port_0=00000000"

loadrt oneshot count=1

setp hm2_[MESA](BOARD).0.watchdog.timeout_ns 10000000

loadrt timedelay count=1

loadrt xor2

loadrt pid names=pid.x,pid.y,pid.z,pid.s

# PID Information for Stepper Boards

# Mesa hardware step generators at every servo thread invocation, the step

# generator hardware is given a new velocity. Without feedback from the PID

# controller the hardware position would slowly drift because of clock speed and

# timing differences between LinuxCNC and the step generator hardware.

# The PID controller gets feedback from the actual (fractional) step position and

# corrects for these small differences.

# THREADS

addf hm2_[MESA](BOARD).0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_[MESA](BOARD).0.write servo-thread

addf timedelay.0 servo-thread

addf xor2.0 servo-thread

# DPLL TIMER

setp hm2_[MESA](BOARD).0.dpll.01.timer-us -50

setp hm2_[MESA](BOARD).0.stepgen.timer-number 1

# amp enable

#net motion-enable <= motion.motion-enabled => hm2_7i95.0.ssr.00.out-02

# Spindle Air Oil solenoid

# Board: 7i95

# Axis: X Joint: 0 Output: 0

# PID Setup

setp pid.x.Pgain [JOINT_0](P)

setp pid.x.Igain [JOINT_0](I)

setp pid.x.Dgain [JOINT_0](D)

setp pid.x.bias [JOINT_0](BIAS)

setp pid.x.FF0 [JOINT_0](FF0)

setp pid.x.FF1 [JOINT_0](FF1)

setp pid.x.FF2 [JOINT_0](FF2)

setp pid.x.deadband [JOINT_0](DEADBAND)

setp pid.x.maxoutput [JOINT_0](MAX_OUTPUT)

setp pid.x.error-previous-target True

# limit stepgen velocity corrections caused by position feedback jitter

setp pid.x.maxerror [JOINT_0](MAX_ERROR)

# joint-0 enable chain

net joint-0-index-enable <=> pid.x.index-enable

net joint-0-index-enable <=> joint.0.index-enable

net joint-0-enable <= joint.0.amp-enable-out

net joint-0-enable => pid.x.enable

net joint-0-enable => hm2_[MESA](BOARD).0.stepgen.00.enable

# Joint 0 Step Generator Settings

setp hm2_[MESA](BOARD).0.stepgen.00.dirsetup [JOINT_0](DIRSETUP)

setp hm2_[MESA](BOARD).0.stepgen.00.dirhold [JOINT_0](DIRHOLD)

setp hm2_[MESA](BOARD).0.stepgen.00.steplen [JOINT_0](STEPLEN)

setp hm2_[MESA](BOARD).0.stepgen.00.stepspace [JOINT_0](STEPSPACE)

setp hm2_[MESA](BOARD).0.stepgen.00.position-scale [JOINT_0](SCALE)

setp hm2_[MESA](BOARD).0.stepgen.00.maxvel [JOINT_0](STEPGEN_MAX_VEL)

setp hm2_[MESA](BOARD).0.stepgen.00.maxaccel [JOINT_0](STEPGEN_MAX_ACC)

setp hm2_[MESA](BOARD).0.stepgen.00.step_type 0

setp hm2_[MESA](BOARD).0.stepgen.00.control-type 1

# position command and feedback

net joint-0-pos-cmd <= joint.0.motor-pos-cmd

net joint-0-pos-cmd => pid.x.command

net joint-0-pos-fb <= hm2_[MESA](BOARD).0.stepgen.00.position-fb

net joint-0-pos-fb => joint.0.motor-pos-fb

net joint-0-pos-fb => pid.x.feedback

# PID Output

net joint.0.output <= pid.x.output

net joint.0.output => hm2_[MESA](BOARD).0.stepgen.00.velocity-cmd

# Axis: Y Joint: 1 Output: 1

# PID Setup

setp pid.y.Pgain [JOINT_1](P)

setp pid.y.Igain [JOINT_1](I)

setp pid.y.Dgain [JOINT_1](D)

setp pid.y.bias [JOINT_1](BIAS)

setp pid.y.FF0 [JOINT_1](FF0)

setp pid.y.FF1 [JOINT_1](FF1)

setp pid.y.FF2 [JOINT_1](FF2)

setp pid.y.deadband [JOINT_1](DEADBAND)

setp pid.y.maxoutput [JOINT_1](MAX_OUTPUT)

setp pid.y.error-previous-target True

# limit stepgen velocity corrections caused by position feedback jitter

setp pid.y.maxerror [JOINT_1](MAX_ERROR)

# joint-1 enable chain

net joint-1-index-enable <=> pid.y.index-enable

net joint-1-index-enable <=> joint.1.index-enable

net joint-1-enable <= joint.1.amp-enable-out

net joint-1-enable => pid.y.enable

net joint-1-enable => hm2_[MESA](BOARD).0.stepgen.01.enable

# Joint 1 Step Generator Settings

setp hm2_[MESA](BOARD).0.stepgen.01.dirsetup [JOINT_1](DIRSETUP)

setp hm2_[MESA](BOARD).0.stepgen.01.dirhold [JOINT_1](DIRHOLD)

setp hm2_[MESA](BOARD).0.stepgen.01.steplen [JOINT_1](STEPLEN)

setp hm2_[MESA](BOARD).0.stepgen.01.stepspace [JOINT_1](STEPSPACE)

setp hm2_[MESA](BOARD).0.stepgen.01.position-scale [JOINT_1](SCALE)

setp hm2_[MESA](BOARD).0.stepgen.01.maxvel [JOINT_1](STEPGEN_MAX_VEL)

setp hm2_[MESA](BOARD).0.stepgen.01.maxaccel [JOINT_1](STEPGEN_MAX_ACC)

setp hm2_[MESA](BOARD).0.stepgen.01.step_type 0

setp hm2_[MESA](BOARD).0.stepgen.01.control-type 1

# position command and feedback

net joint-1-pos-cmd <= joint.1.motor-pos-cmd

net joint-1-pos-cmd => pid.y.command

net joint-1-pos-fb <= hm2_[MESA](BOARD).0.stepgen.01.position-fb

net joint-1-pos-fb => joint.1.motor-pos-fb

net joint-1-pos-fb => pid.y.feedback

# PID Output

net joint.1.output <= pid.y.output

net joint.1.output => hm2_[MESA](BOARD).0.stepgen.01.velocity-cmd

# Axis: Z Joint: 2 Output: 2

# PID Setup

setp pid.z.Pgain [JOINT_2](P)

setp pid.z.Igain [JOINT_2](I)

setp pid.z.Dgain [JOINT_2](D)

setp pid.z.bias [JOINT_2](BIAS)

setp pid.z.FF0 [JOINT_2](FF0)

setp pid.z.FF1 [JOINT_2](FF1)

setp pid.z.FF2 [JOINT_2](FF2)

setp pid.z.deadband [JOINT_2](DEADBAND)

setp pid.z.maxoutput [JOINT_2](MAX_OUTPUT)

setp pid.z.error-previous-target True

# limit stepgen velocity corrections caused by position feedback jitter

setp pid.z.maxerror [JOINT_2](MAX_ERROR)

# joint-2 enable chain

net joint-2-index-enable <=> pid.z.index-enable

net joint-2-index-enable <=> joint.2.index-enable

net joint-2-enable <= joint.2.amp-enable-out

net joint-2-enable => pid.z.enable

net joint-2-enable => hm2_[MESA](BOARD).0.stepgen.02.enable

# Joint 2 Step Generator Settings

setp hm2_[MESA](BOARD).0.stepgen.02.dirsetup [JOINT_2](DIRSETUP)

setp hm2_[MESA](BOARD).0.stepgen.02.dirhold [JOINT_2](DIRHOLD)

setp hm2_[MESA](BOARD).0.stepgen.02.steplen [JOINT_2](STEPLEN)

setp hm2_[MESA](BOARD).0.stepgen.02.stepspace [JOINT_2](STEPSPACE)

setp hm2_[MESA](BOARD).0.stepgen.02.position-scale [JOINT_2](SCALE)

setp hm2_[MESA](BOARD).0.stepgen.02.maxvel [JOINT_2](STEPGEN_MAX_VEL)

setp hm2_[MESA](BOARD).0.stepgen.02.maxaccel [JOINT_2](STEPGEN_MAX_ACC)

setp hm2_[MESA](BOARD).0.stepgen.02.step_type 0

setp hm2_[MESA](BOARD).0.stepgen.02.control-type 1

# position command and feedback

net joint-2-pos-cmd <= joint.2.motor-pos-cmd

net joint-2-pos-cmd => pid.z.command

net joint-2-pos-fb <= hm2_[MESA](BOARD).0.stepgen.02.position-fb

net joint-2-pos-fb => joint.2.motor-pos-fb

net joint-2-pos-fb => pid.z.feedback

# PID Output

net joint.2.output <= pid.z.output

net joint.2.output => hm2_[MESA](BOARD).0.stepgen.02.velocity-cmd

# Manual Tool Change Dialog

loadusr -W hal_manualtoolchange

net tool-change-request => hal_manualtoolchange.change

net tool-change-confirmed <= hal_manualtoolchange.changed

net tool-number => hal_manualtoolchange.number

# create signals for tool loading loopback

net tool-prep-loop iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

net tool-change-loop iocontrol.0.tool-change => iocontrol.0.tool-changed

# # Load Classicladder without GUI

loadrt classicladder_rt

addf classicladder.0.refresh servo-thread 1

# E-Stop Chain

loadrt estop_latch count=1

addf estop-latch.0 servo-thread

# E-Stop Loop

net estop-loopin iocontrol.0.user-enable-out => estop-latch.0.ok-in

net estop-loopout estop-latch.0.ok-out => iocontrol.0.emc-enable-in

# E-Stop Reset

net estop-reset iocontrol.0.user-request-enable

net estop-reset => estop-latch.0.reset

net remote-estop0 estop-latch.0.fault-in <= hm2_7i95.0.inmux.00.input-01-not

# Input and output configuration

net button-press <= hm2_7i95.0.inmux.00.input-05 # Connect input pin 5 to signal button-press

net relay-1-control => hm2_7i95.0.ssr.00.out-01 # Connect signal relay-1-control to relay output 1

net relay-2-control => hm2_7i95.0.ssr.00.out-03 # Connect signal relay-2-control to relay output 3

setp timedelay.0.on-delay 1.0 # 1-second delay

setp timedelay.0.off-delay 0.0 # No off delay

# Timedelay connections

net button-press => timedelay.0.in xor.0.in0 # Link button-press to timedelay and logic

net relay-1-control <= timedelay.0.out xor.0.in1 # Link timedelay output to relay-1-control and logic

net relay-2-control <= xor.0.out # Link xor out to relay-2-control

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]MAX_OUTPUT

setp pid.s.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.s.maxerror 0.012700

net spindle-index-enable => pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm => pid.s.command

net spindle-vel-fb-rpm => pid.s.feedback

net spindle-output <= pid.s.output

# Step Gen signals/setup

setp hm2_[MESA](BOARD).0.stepgen.03.dirsetup [SPINDLE_0]DIRSETUP

setp hm2_[MESA](BOARD).0.stepgen.03.dirhold [SPINDLE_0]DIRHOLD

setp hm2_[MESA](BOARD).0.stepgen.03.steplen [SPINDLE_0]STEPLEN

setp hm2_[MESA](BOARD).0.stepgen.03.stepspace [SPINDLE_0]STEPSPACE

setp hm2_[MESA](BOARD).0.stepgen.03.position-scale [SPINDLE_0]SCALE

setp hm2_[MESA](BOARD).0.stepgen.03.step_type 0

setp hm2_[MESA](BOARD).0.stepgen.03.control-type 1

setp hm2_[MESA](BOARD).0.stepgen.03.maxaccel [SPINDLE_0]STEPGEN_MAX_ACC

setp hm2_[MESA](BOARD).0.stepgen.03.maxvel [SPINDLE_0]STEPGEN_MAX_VEL

net machine-is-on => hm2_[MESA](BOARD).0.stepgen.03.enable

net spindle-vel-cmd-rps => hm2_[MESA](BOARD).0.stepgen.03.velocity-cmd

net spindle-vel-fb-rps <= hm2_[MESA](BOARD).0.stepgen.03.velocity-fb

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

here is my hal file

# This file was created with the Mesa Configuration Tool on Nov 26 2024 15:50:59

# If you make changes to this file DO NOT run the configuration tool again!

# This file will be replaced with a new file if you do!

# kinematics

loadrt [KINS](KINEMATICS)

# motion controller

loadrt [EMCMOT](EMCMOT) servo_period_nsec=[EMCMOT](SERVO_PERIOD) num_joints=[KINS]JOINTS num_dio=30 num_aio=30

# hostmot2 driver

loadrt hostmot2

loadrt [HM2](DRIVER) board_ip=[HM2](ADDRESS) config="sserial_port_0=00000000"

loadrt oneshot count=1

setp hm2_[MESA](BOARD).0.watchdog.timeout_ns 10000000

loadrt timedelay count=1

loadrt xor2

loadrt pid names=pid.x,pid.y,pid.z,pid.s

# PID Information for Stepper Boards

# Mesa hardware step generators at every servo thread invocation, the step

# generator hardware is given a new velocity. Without feedback from the PID

# controller the hardware position would slowly drift because of clock speed and

# timing differences between LinuxCNC and the step generator hardware.

# The PID controller gets feedback from the actual (fractional) step position and

# corrects for these small differences.

# THREADS

addf hm2_[MESA](BOARD).0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_[MESA](BOARD).0.write servo-thread

addf timedelay.0 servo-thread

addf xor2.0 servo-thread

# DPLL TIMER

setp hm2_[MESA](BOARD).0.dpll.01.timer-us -50

setp hm2_[MESA](BOARD).0.stepgen.timer-number 1

# amp enable

#net motion-enable <= motion.motion-enabled => hm2_7i95.0.ssr.00.out-02

# Spindle Air Oil solenoid

# Board: 7i95

# Axis: X Joint: 0 Output: 0

# PID Setup

setp pid.x.Pgain [JOINT_0](P)

setp pid.x.Igain [JOINT_0](I)

setp pid.x.Dgain [JOINT_0](D)

setp pid.x.bias [JOINT_0](BIAS)

setp pid.x.FF0 [JOINT_0](FF0)

setp pid.x.FF1 [JOINT_0](FF1)

setp pid.x.FF2 [JOINT_0](FF2)

setp pid.x.deadband [JOINT_0](DEADBAND)

setp pid.x.maxoutput [JOINT_0](MAX_OUTPUT)

setp pid.x.error-previous-target True

# limit stepgen velocity corrections caused by position feedback jitter

setp pid.x.maxerror [JOINT_0](MAX_ERROR)

# joint-0 enable chain

net joint-0-index-enable <=> pid.x.index-enable

net joint-0-index-enable <=> joint.0.index-enable

net joint-0-enable <= joint.0.amp-enable-out

net joint-0-enable => pid.x.enable

net joint-0-enable => hm2_[MESA](BOARD).0.stepgen.00.enable

# Joint 0 Step Generator Settings

setp hm2_[MESA](BOARD).0.stepgen.00.dirsetup [JOINT_0](DIRSETUP)

setp hm2_[MESA](BOARD).0.stepgen.00.dirhold [JOINT_0](DIRHOLD)

setp hm2_[MESA](BOARD).0.stepgen.00.steplen [JOINT_0](STEPLEN)

setp hm2_[MESA](BOARD).0.stepgen.00.stepspace [JOINT_0](STEPSPACE)

setp hm2_[MESA](BOARD).0.stepgen.00.position-scale [JOINT_0](SCALE)

setp hm2_[MESA](BOARD).0.stepgen.00.maxvel [JOINT_0](STEPGEN_MAX_VEL)

setp hm2_[MESA](BOARD).0.stepgen.00.maxaccel [JOINT_0](STEPGEN_MAX_ACC)

setp hm2_[MESA](BOARD).0.stepgen.00.step_type 0

setp hm2_[MESA](BOARD).0.stepgen.00.control-type 1

# position command and feedback

net joint-0-pos-cmd <= joint.0.motor-pos-cmd

net joint-0-pos-cmd => pid.x.command

net joint-0-pos-fb <= hm2_[MESA](BOARD).0.stepgen.00.position-fb

net joint-0-pos-fb => joint.0.motor-pos-fb

net joint-0-pos-fb => pid.x.feedback

# PID Output

net joint.0.output <= pid.x.output

net joint.0.output => hm2_[MESA](BOARD).0.stepgen.00.velocity-cmd

# Axis: Y Joint: 1 Output: 1

# PID Setup

setp pid.y.Pgain [JOINT_1](P)

setp pid.y.Igain [JOINT_1](I)

setp pid.y.Dgain [JOINT_1](D)

setp pid.y.bias [JOINT_1](BIAS)

setp pid.y.FF0 [JOINT_1](FF0)

setp pid.y.FF1 [JOINT_1](FF1)

setp pid.y.FF2 [JOINT_1](FF2)

setp pid.y.deadband [JOINT_1](DEADBAND)

setp pid.y.maxoutput [JOINT_1](MAX_OUTPUT)

setp pid.y.error-previous-target True

# limit stepgen velocity corrections caused by position feedback jitter

setp pid.y.maxerror [JOINT_1](MAX_ERROR)

# joint-1 enable chain

net joint-1-index-enable <=> pid.y.index-enable

net joint-1-index-enable <=> joint.1.index-enable

net joint-1-enable <= joint.1.amp-enable-out

net joint-1-enable => pid.y.enable

net joint-1-enable => hm2_[MESA](BOARD).0.stepgen.01.enable

# Joint 1 Step Generator Settings

setp hm2_[MESA](BOARD).0.stepgen.01.dirsetup [JOINT_1](DIRSETUP)

setp hm2_[MESA](BOARD).0.stepgen.01.dirhold [JOINT_1](DIRHOLD)

setp hm2_[MESA](BOARD).0.stepgen.01.steplen [JOINT_1](STEPLEN)

setp hm2_[MESA](BOARD).0.stepgen.01.stepspace [JOINT_1](STEPSPACE)

setp hm2_[MESA](BOARD).0.stepgen.01.position-scale [JOINT_1](SCALE)

setp hm2_[MESA](BOARD).0.stepgen.01.maxvel [JOINT_1](STEPGEN_MAX_VEL)

setp hm2_[MESA](BOARD).0.stepgen.01.maxaccel [JOINT_1](STEPGEN_MAX_ACC)

setp hm2_[MESA](BOARD).0.stepgen.01.step_type 0

setp hm2_[MESA](BOARD).0.stepgen.01.control-type 1

# position command and feedback

net joint-1-pos-cmd <= joint.1.motor-pos-cmd

net joint-1-pos-cmd => pid.y.command

net joint-1-pos-fb <= hm2_[MESA](BOARD).0.stepgen.01.position-fb

net joint-1-pos-fb => joint.1.motor-pos-fb

net joint-1-pos-fb => pid.y.feedback

# PID Output

net joint.1.output <= pid.y.output

net joint.1.output => hm2_[MESA](BOARD).0.stepgen.01.velocity-cmd

# Axis: Z Joint: 2 Output: 2

# PID Setup

setp pid.z.Pgain [JOINT_2](P)

setp pid.z.Igain [JOINT_2](I)

setp pid.z.Dgain [JOINT_2](D)

setp pid.z.bias [JOINT_2](BIAS)

setp pid.z.FF0 [JOINT_2](FF0)

setp pid.z.FF1 [JOINT_2](FF1)

setp pid.z.FF2 [JOINT_2](FF2)

setp pid.z.deadband [JOINT_2](DEADBAND)

setp pid.z.maxoutput [JOINT_2](MAX_OUTPUT)

setp pid.z.error-previous-target True

# limit stepgen velocity corrections caused by position feedback jitter

setp pid.z.maxerror [JOINT_2](MAX_ERROR)

# joint-2 enable chain

net joint-2-index-enable <=> pid.z.index-enable

net joint-2-index-enable <=> joint.2.index-enable

net joint-2-enable <= joint.2.amp-enable-out

net joint-2-enable => pid.z.enable

net joint-2-enable => hm2_[MESA](BOARD).0.stepgen.02.enable

# Joint 2 Step Generator Settings

setp hm2_[MESA](BOARD).0.stepgen.02.dirsetup [JOINT_2](DIRSETUP)

setp hm2_[MESA](BOARD).0.stepgen.02.dirhold [JOINT_2](DIRHOLD)

setp hm2_[MESA](BOARD).0.stepgen.02.steplen [JOINT_2](STEPLEN)

setp hm2_[MESA](BOARD).0.stepgen.02.stepspace [JOINT_2](STEPSPACE)

setp hm2_[MESA](BOARD).0.stepgen.02.position-scale [JOINT_2](SCALE)

setp hm2_[MESA](BOARD).0.stepgen.02.maxvel [JOINT_2](STEPGEN_MAX_VEL)

setp hm2_[MESA](BOARD).0.stepgen.02.maxaccel [JOINT_2](STEPGEN_MAX_ACC)

setp hm2_[MESA](BOARD).0.stepgen.02.step_type 0

setp hm2_[MESA](BOARD).0.stepgen.02.control-type 1

# position command and feedback

net joint-2-pos-cmd <= joint.2.motor-pos-cmd

net joint-2-pos-cmd => pid.z.command

net joint-2-pos-fb <= hm2_[MESA](BOARD).0.stepgen.02.position-fb

net joint-2-pos-fb => joint.2.motor-pos-fb

net joint-2-pos-fb => pid.z.feedback

# PID Output

net joint.2.output <= pid.z.output

net joint.2.output => hm2_[MESA](BOARD).0.stepgen.02.velocity-cmd

# Manual Tool Change Dialog

loadusr -W hal_manualtoolchange

net tool-change-request => hal_manualtoolchange.change

net tool-change-confirmed <= hal_manualtoolchange.changed

net tool-number => hal_manualtoolchange.number

# create signals for tool loading loopback

net tool-prep-loop iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

net tool-change-loop iocontrol.0.tool-change => iocontrol.0.tool-changed

# # Load Classicladder without GUI

loadrt classicladder_rt

addf classicladder.0.refresh servo-thread 1

# E-Stop Chain

loadrt estop_latch count=1

addf estop-latch.0 servo-thread

# E-Stop Loop

net estop-loopin iocontrol.0.user-enable-out => estop-latch.0.ok-in

net estop-loopout estop-latch.0.ok-out => iocontrol.0.emc-enable-in

# E-Stop Reset

net estop-reset iocontrol.0.user-request-enable

net estop-reset => estop-latch.0.reset

net remote-estop0 estop-latch.0.fault-in <= hm2_7i95.0.inmux.00.input-01-not

# Input and output configuration

net button-press <= hm2_7i95.0.inmux.00.input-05 # Connect input pin 5 to signal button-press

net relay-1-control => hm2_7i95.0.ssr.00.out-01 # Connect signal relay-1-control to relay output 1

net relay-2-control => hm2_7i95.0.ssr.00.out-03 # Connect signal relay-2-control to relay output 3

setp timedelay.0.on-delay 1.0 # 1-second delay

setp timedelay.0.off-delay 0.0 # No off delay

# Timedelay connections

net button-press => timedelay.0.in xor.0.in0 # Link button-press to timedelay and logic

net relay-1-control <= timedelay.0.out xor.0.in1 # Link timedelay output to relay-1-control and logic

net relay-2-control <= xor.0.out # Link xor out to relay-2-control

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]MAX_OUTPUT

setp pid.s.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.s.maxerror 0.012700

net spindle-index-enable => pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm => pid.s.command

net spindle-vel-fb-rpm => pid.s.feedback

net spindle-output <= pid.s.output

# Step Gen signals/setup

setp hm2_[MESA](BOARD).0.stepgen.03.dirsetup [SPINDLE_0]DIRSETUP

setp hm2_[MESA](BOARD).0.stepgen.03.dirhold [SPINDLE_0]DIRHOLD

setp hm2_[MESA](BOARD).0.stepgen.03.steplen [SPINDLE_0]STEPLEN

setp hm2_[MESA](BOARD).0.stepgen.03.stepspace [SPINDLE_0]STEPSPACE

setp hm2_[MESA](BOARD).0.stepgen.03.position-scale [SPINDLE_0]SCALE

setp hm2_[MESA](BOARD).0.stepgen.03.step_type 0

setp hm2_[MESA](BOARD).0.stepgen.03.control-type 1

setp hm2_[MESA](BOARD).0.stepgen.03.maxaccel [SPINDLE_0]STEPGEN_MAX_ACC

setp hm2_[MESA](BOARD).0.stepgen.03.maxvel [SPINDLE_0]STEPGEN_MAX_VEL

net machine-is-on => hm2_[MESA](BOARD).0.stepgen.03.enable

net spindle-vel-cmd-rps => hm2_[MESA](BOARD).0.stepgen.03.velocity-cmd

net spindle-vel-fb-rps <= hm2_[MESA](BOARD).0.stepgen.03.velocity-fb

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

Time to create page: 1.424 seconds