Search Results (Searched for: 7i76e)

- DerKlotz

- DerKlotz

12 Oct 2025 14:42

Replied by DerKlotz on topic Button on Linuxcnc interface that switches an output on Mesa 7i76e on and off

Button on Linuxcnc interface that switches an output on Mesa 7i76e on and off

Category: GladeVCP

- PCW

12 Oct 2025 14:19 - 12 Oct 2025 14:19

- DerKlotz

- DerKlotz

12 Oct 2025 14:04 - 12 Oct 2025 14:05

Replied by DerKlotz on topic Button on Linuxcnc interface that switches an output on Mesa 7i76e on and off

Button on Linuxcnc interface that switches an output on Mesa 7i76e on and off

Category: GladeVCP

- Aciera

12 Oct 2025 11:54

- DerKlotz

- DerKlotz

12 Oct 2025 11:06 - 12 Oct 2025 11:36

Replied by DerKlotz on topic Button on Linuxcnc interface that switches an output on Mesa 7i76e on and off

Button on Linuxcnc interface that switches an output on Mesa 7i76e on and off

Category: GladeVCP

- Aciera

12 Oct 2025 01:30

- bnet

11 Oct 2025 15:40

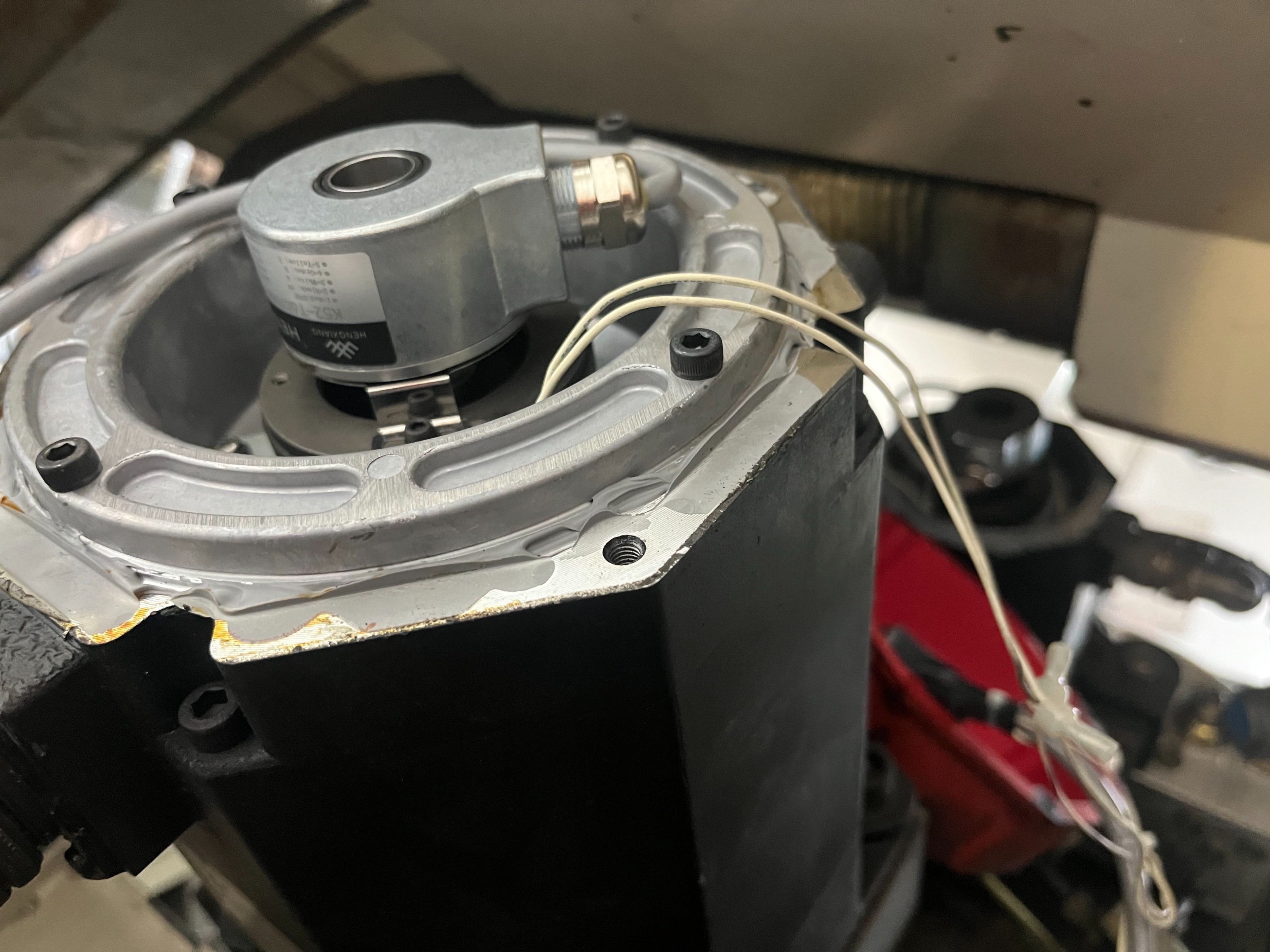

Replied by bnet on topic Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Category: Driver Boards

- DerKlotz

- DerKlotz

11 Oct 2025 14:15 - 11 Oct 2025 14:59

Replied by DerKlotz on topic Button on Linuxcnc interface that switches an output on Mesa 7i76e on and off

Button on Linuxcnc interface that switches an output on Mesa 7i76e on and off

Category: GladeVCP

- Aciera

11 Oct 2025 07:29

- andypugh

10 Oct 2025 20:03

Replied by andypugh on topic Button on Linuxcnc interface that switches an output on Mesa 7i76e on and off

Button on Linuxcnc interface that switches an output on Mesa 7i76e on and off

Category: GladeVCP

- DerKlotz

- DerKlotz

10 Oct 2025 18:50

Replied by DerKlotz on topic Button on Linuxcnc interface that switches an output on Mesa 7i76e on and off

Button on Linuxcnc interface that switches an output on Mesa 7i76e on and off

Category: GladeVCP

- Aciera

10 Oct 2025 17:26

- Aciera

10 Oct 2025 17:25

- DerKlotz

- DerKlotz

10 Oct 2025 16:58

Replied by DerKlotz on topic Button on Linuxcnc interface that switches an output on Mesa 7i76e on and off

Button on Linuxcnc interface that switches an output on Mesa 7i76e on and off

Category: GladeVCP

- Aciera

10 Oct 2025 15:12 - 10 Oct 2025 15:15

Time to create page: 1.177 seconds