Search Results (Searched for: 7i76e)

31 Oct 2023 17:26

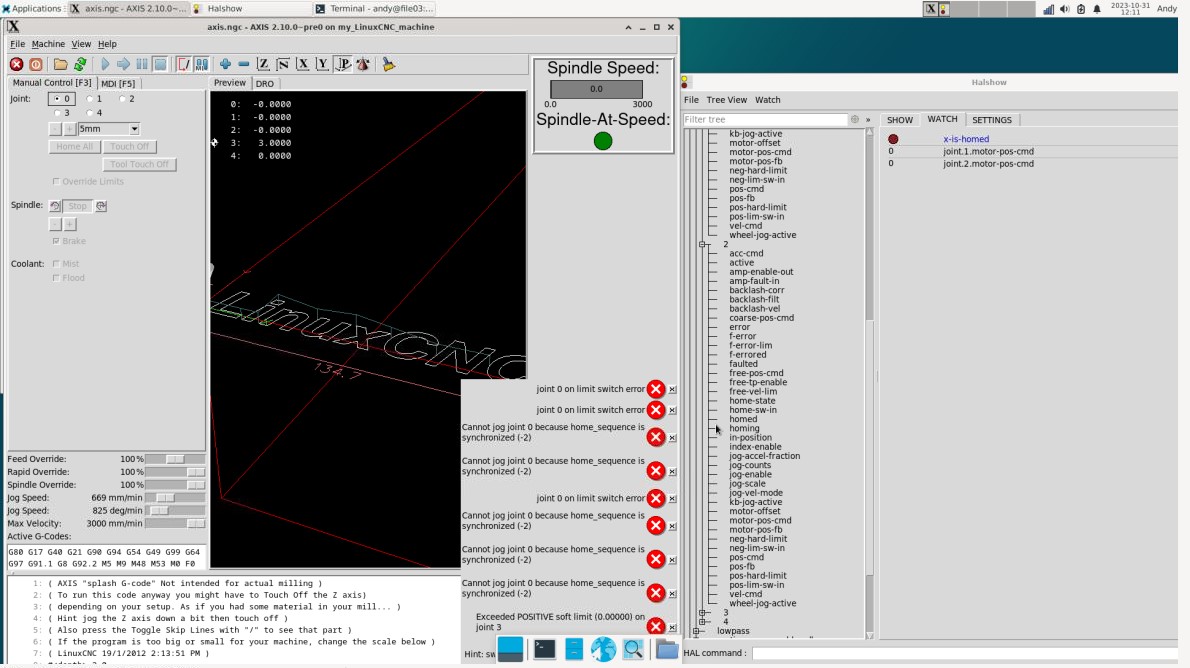

Replied by gardenweazel on topic Tandem Y Axis not working on 7i76E

Tandem Y Axis not working on 7i76E

Category: General LinuxCNC Questions

31 Oct 2023 16:30

Replied by PCW on topic Tandem Y Axis not working on 7i76E

Tandem Y Axis not working on 7i76E

Category: General LinuxCNC Questions

31 Oct 2023 15:28 - 31 Oct 2023 15:30

Replied by gardenweazel on topic Tandem Y Axis not working on 7i76E

Tandem Y Axis not working on 7i76E

Category: General LinuxCNC Questions

31 Oct 2023 15:16

Replied by PCW on topic Tandem Y Axis not working on 7i76E

Tandem Y Axis not working on 7i76E

Category: General LinuxCNC Questions

31 Oct 2023 14:28 - 31 Oct 2023 14:38

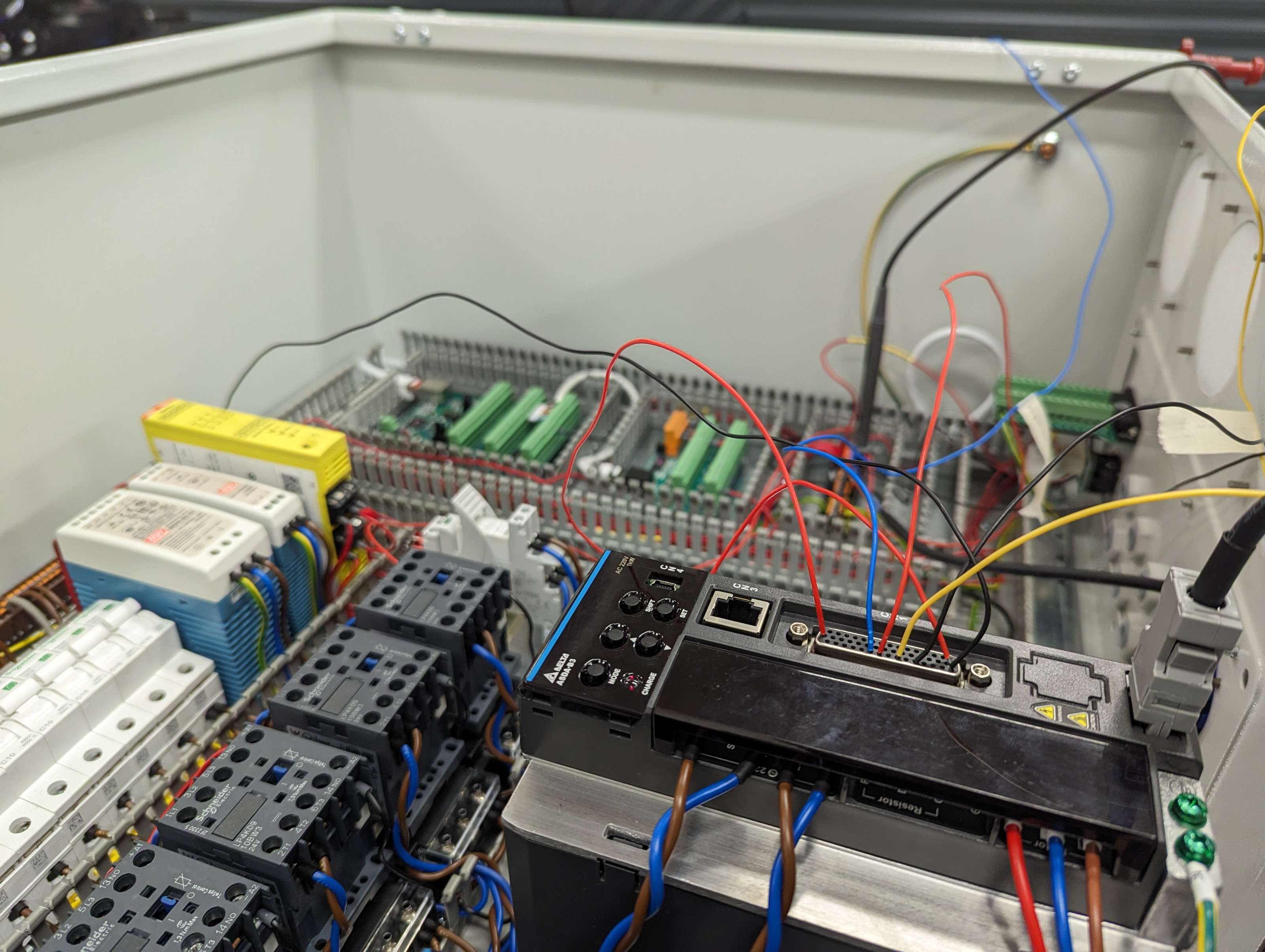

Tandem Y Axis not working on 7i76E was created by gardenweazel

Tandem Y Axis not working on 7i76E

Category: General LinuxCNC Questions

31 Oct 2023 13:37

Replied by jogger on topic PID for spindle with 7i76e A/B encoder AND index (Z)

PID for spindle with 7i76e A/B encoder AND index (Z)

Category: Advanced Configuration

30 Oct 2023 14:07 - 30 Oct 2023 14:08

Replied by PCW on topic PID for spindle with 7i76e A/B encoder AND index (Z)

PID for spindle with 7i76e A/B encoder AND index (Z)

Category: Advanced Configuration

30 Oct 2023 10:48

29 Oct 2023 20:01

Replied by MaHa on topic Handrad XHC richtig einbinden in LinuxCNC

Handrad XHC richtig einbinden in LinuxCNC

Category: Deutsch

29 Oct 2023 15:22

Handrad XHC richtig einbinden in LinuxCNC was created by tracer

Handrad XHC richtig einbinden in LinuxCNC

Category: Deutsch

28 Oct 2023 10:06

28 Oct 2023 09:10

28 Oct 2023 09:02

28 Oct 2023 08:47

25 Oct 2023 09:16

Time to create page: 0.922 seconds