Category: User Exchange

I wrote this up in chat gpt pretty quickly I think it just about covers all of the bases here of the project.

CNC Plasma Table – Electrical & Wiring Requirements

Project: Remote design of electrical system + wiring documentation for LinuxCNC plasma table

Client: TCB Metal Works

1. Project Overview

You will remotely design the complete electrical and control system for a custom CNC plasma cutting table powered by LinuxCNC.

You will create:

Complete wiring diagram set (schematic + physical routing)

Full Bill of Materials (BOM) with real part numbers

Wire gauge, shielding, grounding, and EMI mitigation plan

Bulkhead connector list + panel layout

Mesa board selection + full LinuxCNC I/O map

Integration notes for all components

Testing & commissioning checklist

This is a 100% remote engineering job — no physical inspection of hardware is required.

2. Available Power Sources

Near the machine:

220 VAC available

460 VAC available

No dedicated 110/120 VAC, which must be generated using a control transformer if needed

Engineer must design the incoming power strategy and transformer selection.

3. Motion Hardware

3.1 X & Y Axis – AC Servos (Provided)

3× A6 Series 1000W RS485 AC Servo Motor Kits

3000 rpm

3.18 Nm

17-bit absolute encoder

IP67 motors

Axis layout:

Y axis: 2 servos (dual-drive gantry)

X axis: 1 servo

Notes:

Motor-to-drive cables are already supplied by the manufacturer.

You do not need to design or evaluate those cables.

Engineer must:

Design AC mains wiring to each servo drive

Design control, enable, alarm, and ESTOP signal wiring between drives and Mesa

Include needed fuses, breakers, filters, and terminals

Provide cabinet layout and routing plan

Include proper grounding and shielding recommendations

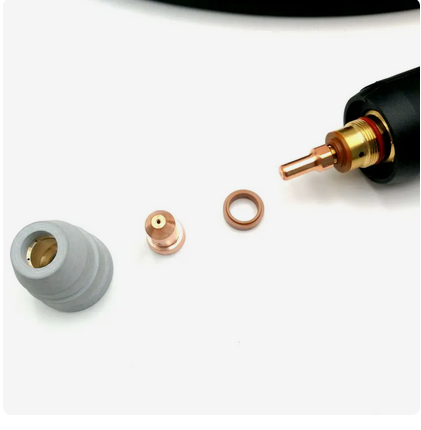

3.2 Z Axis – Stepper Motor (Needs Driver + Cable)

PV267-D2.8AA stepper motor — Oriental Motor

Stepper driver not provided

Stepper motor cable not provided

Engineer must:

Select a compatible stepper driver suitable for PV267-D2.8AA + LinuxCNC step/dir

Define driver voltage supply requirements

Design:

Step/Dir wiring from Mesa

Motor wiring from driver to Z motor

Required cable shielding, gauge, and insulation

Connector type and strain relief

4. Control Electronics (Mesa + Power)

Engineer must select Mesa hardware capable of supporting:

3× servo axes

1× stepper axis

THC-AD

Ohmic sensing

All limit/floating switches

Plasma start / Arc OK

E-stop & safety I/O

Deliverables:

Recommended Mesa board combination (e.g., 7i76E, 7i96S, 7i85, THCAD, etc.)

Justification for chosen hardware

Complete LinuxCNC I/O mapping

Required DC power supplies (24V / 5V / others)

Proper AC distribution, fuses, breakers, and protection devices

5. Torch Height & Ohmic Sensing

5.1 THC-AD Integration

Engineer must design:

Raw arc voltage wiring from Hypertherm HT2000 to THC-AD

THC-AD signal wiring to Mesa

Required shielding and filtering

Scaling notes for LinuxCNC

5.2 Ohmic Sensing (Planned)

Engineer must:

Recommend a compatible ohmic board

Provide wiring diagram for torch → ohmic board → Mesa

Specify cable type and shielding

Document signal polarity & behavior

6. Hypertherm HT2000 Integration

Engineer must design wiring for:

Required signals

Torch start / trigger

Arc OK

Raw arc voltage (+/–) into THC-AD

Required protection

Isolation (if needed)

Surge suppression

Filtering

EMI protection

Routing rules

Arc voltage wiring must be kept separate from low-voltage control wiring

7. Limit Switches & Floating Head

X Axis

2 limit switches:

X-min

X-max

Y Axis (Dual Gantry Drive)

2 limit switches:

Y-min

Y-max

Engineer must propose a reliable gantry squaring / homing method for the two Y motors.

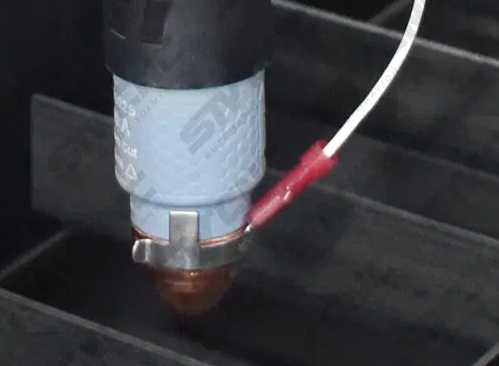

Z Axis

2 end-of-travel limit switches:

Z-min

Z-max

1 floating-head switch (touch-off)

Engineer must:

Select appropriate switch type (mechanical or prox)

Provide wiring diagrams to Mesa

Specify wire gauge, shielding, and cable routing

Provide LinuxCNC input mapping

Include any debouncing/filtering requirements

8. Wiring, Shielding, & EMI

Engineer must specify:

Wire gauges for:

AC mains

Servo drive feeds

Stepper driver feeds

Stepper motor wiring

Limit/floating/ohmic wires

Plasma signals

DC supply lines

Shielding requirements for:

Step/dir

Limits/floating/ohmic

Arc voltage

THC-AD lines

EMI considerations

Cable separation

Ferrite locations

Filtering recommendations

9. Grounding & Bonding

The engineer must design the grounding/bonding approach.

Important physical detail:

The water table, gantry, and control cabinet are three separate physical assemblies.

The engineer must account for this when designing:

Grounding/bonding layout

EMC/EMI mitigation

Plasma return path considerations

Ohmic sensing grounding

No grounding method (star, bus, single-point, etc.) is mandated — the engineer chooses the correct approach.

10. Control Cabinet & Bulkheads

Engineer must design:

Cabinet Layout

AC distribution, transformers, PSUs

Mesa boards

Servo drives

Stepper driver

Fuses, breakers, contactors

DIN rail layout

Ventilation/fans

Bulkhead Connectors

Used wherever practical for:

Servo cables (using glands or pass-throughs)

Z stepper cable

Limit/floating switches

Ohmic sensing

Plasma start / Arc OK

E-stop / operator controls

Ethernet access

Engineer must specify:

Connector type

Pinout

Panel cutout style

Labeling

11. Documentation Package

Engineer must deliver:

11.1 Wiring Diagram Set

Full schematic

Cabinet wiring

Field wiring

Power distribution

Grounding/bonding

Bulkhead connector pinouts

11.2 BOM

Complete list of:

Mesa hardware

Stepper driver

Transformers / PSUs

Switches

Connectors

Wire/cable

Protection devices

Cabinet hardware

11.3 I/O Map

All LinuxCNC inputs/outputs

Axis definitions

THC/ohmic mappings

E-stop & safety signals

11.4 Commissioning Checklist

Power-up verification

Servo enable/jog

Stepper test

Homing / gantry squaring

Z floating-head test

Plasma start / Arc OK

THC test

Ohmic test

EMI/noise checks