Search Results (Searched for: )

- RotarySMP

Today 20:00

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

Schaublin 125-CNC retrofit.

Category: Turning

- Dudelbert

- Dudelbert

Today 19:54

Replied by Dudelbert on topic Considering a Full Rewire on a Working Schaublin 125 CNC

Considering a Full Rewire on a Working Schaublin 125 CNC

Category: Turning

- Finngineering

- Finngineering

Today 19:42

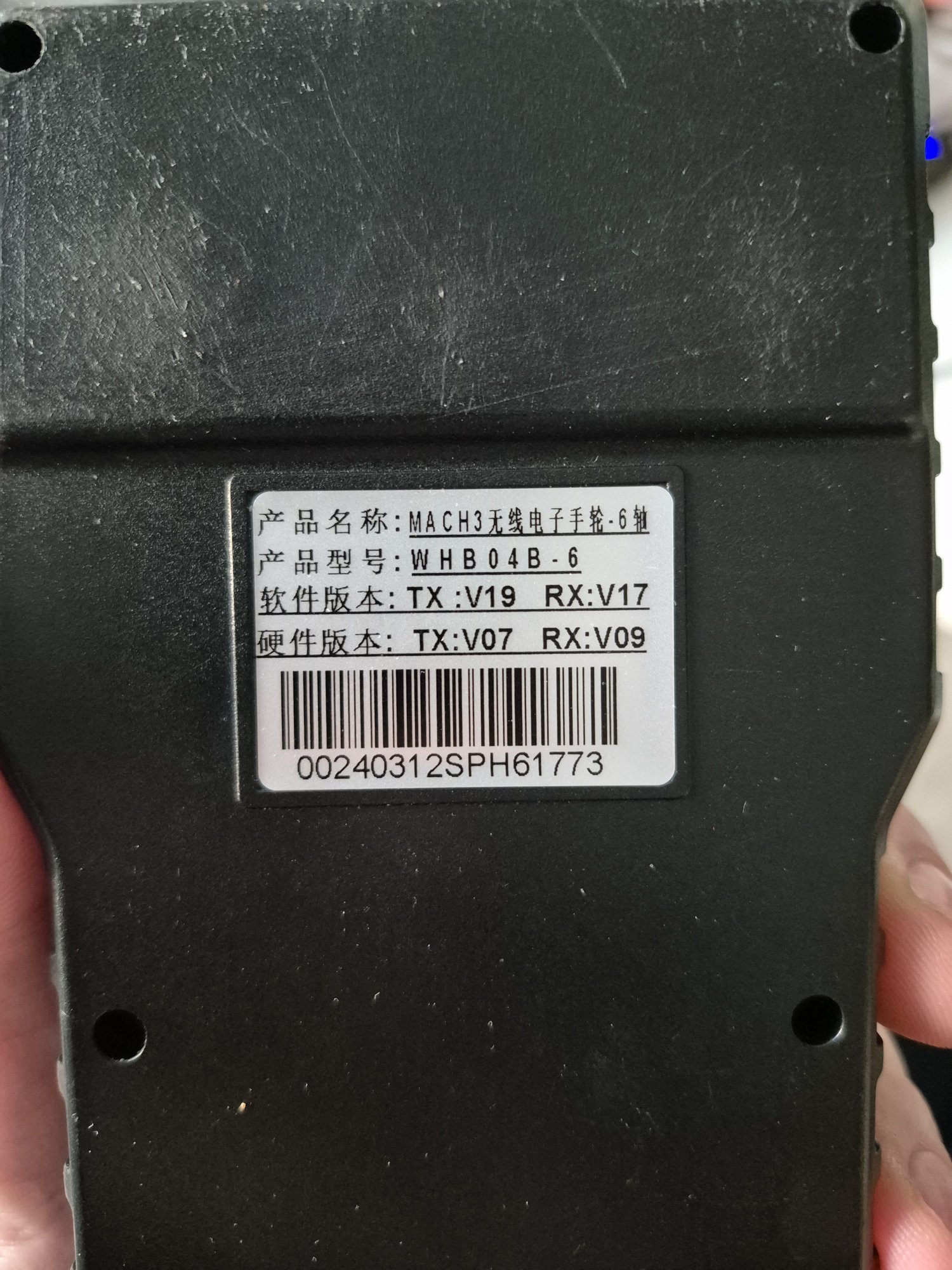

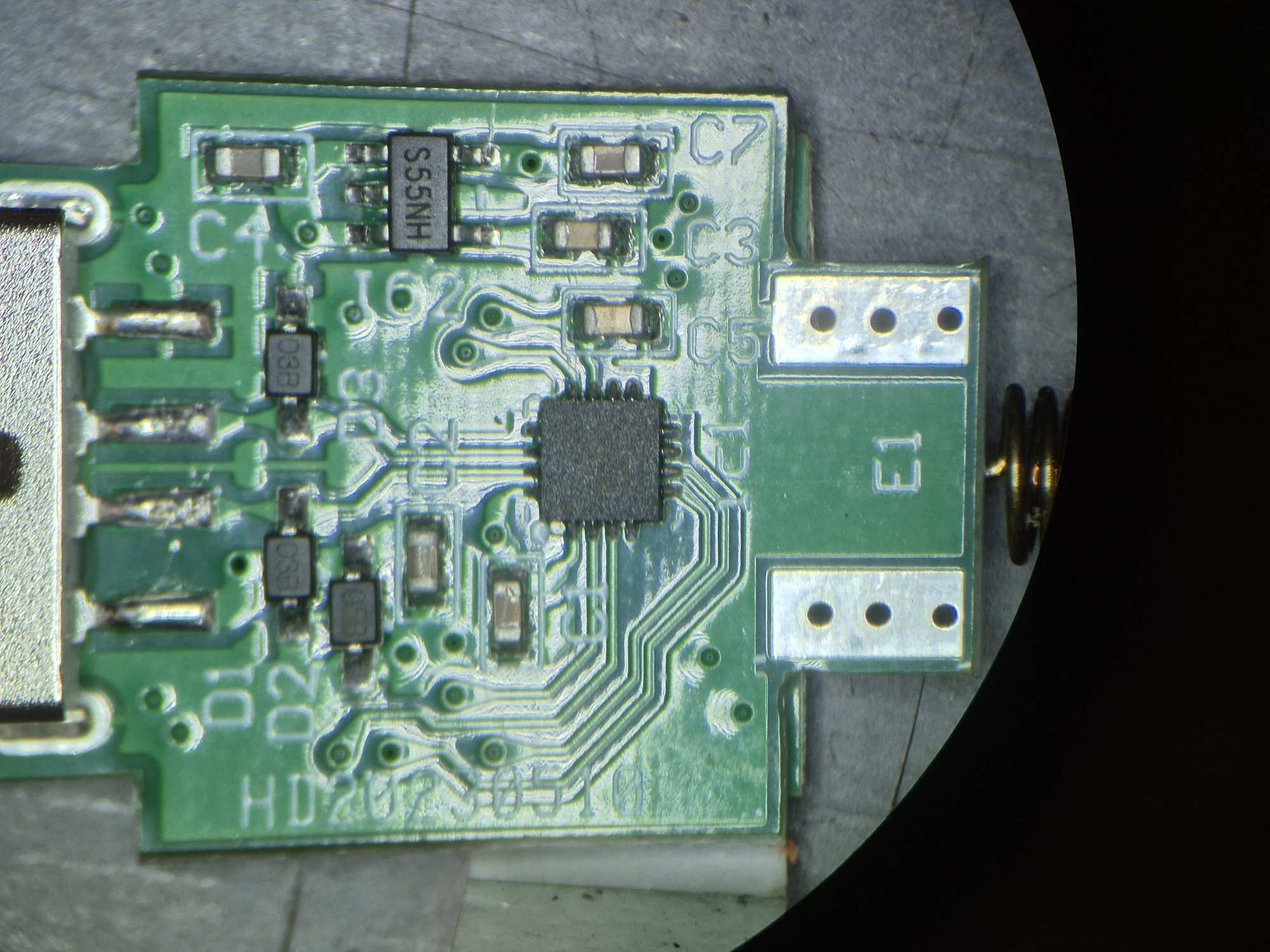

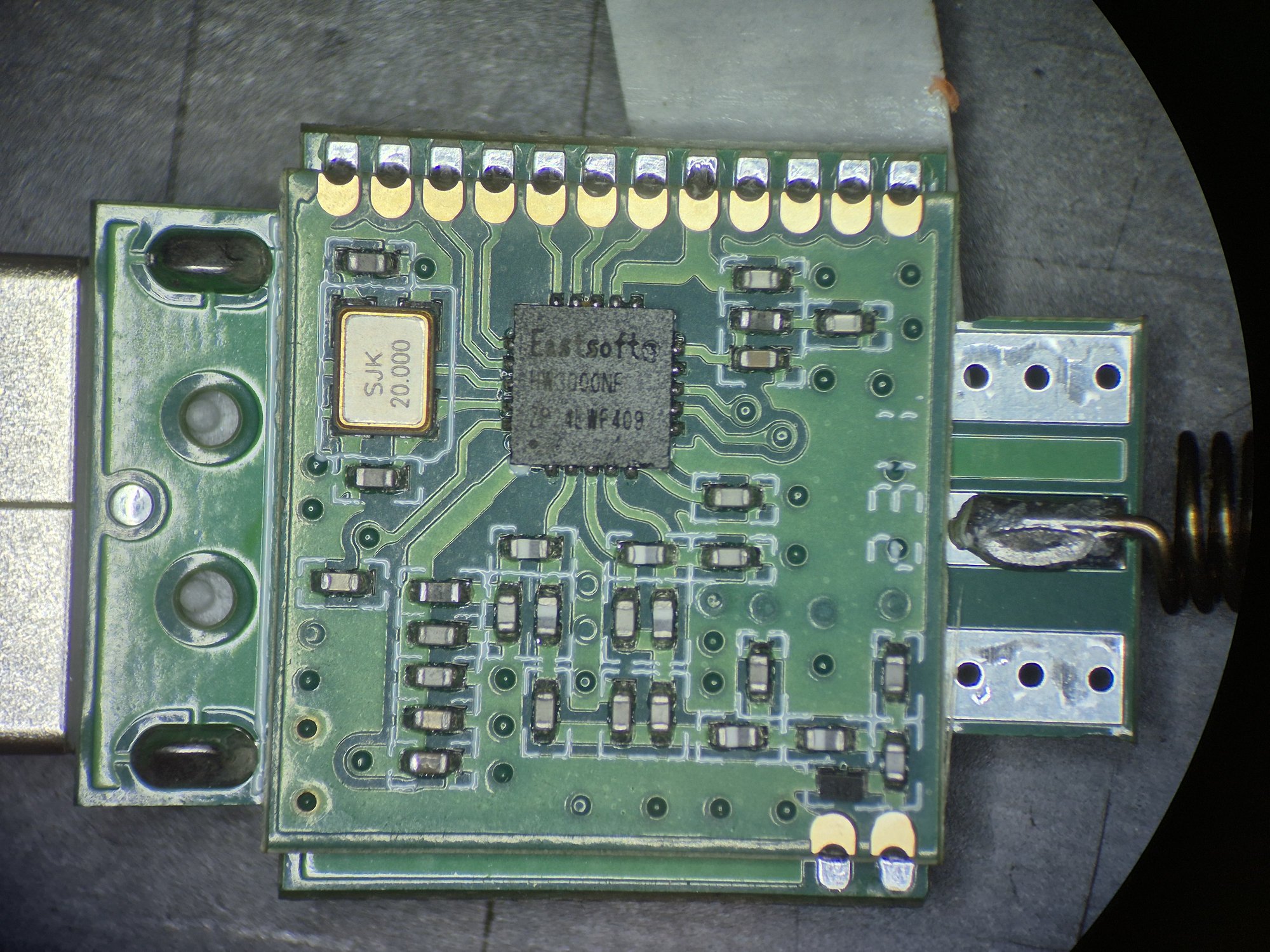

Replied by Finngineering on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- RotarySMP

Today 19:36

Replied by RotarySMP on topic Considering a Full Rewire on a Working Schaublin 125 CNC

Considering a Full Rewire on a Working Schaublin 125 CNC

Category: Turning

- AlessandroEmm

- AlessandroEmm

Today 18:49 - Today 19:06

Replied by AlessandroEmm on topic Remora - Cannot clear E-STOP, without error

Remora - Cannot clear E-STOP, without error

Category: Basic Configuration

- PCW

Today 18:37

- Todd Zuercher

Today 17:38

- Konstantin

- Konstantin

Today 17:25 - Today 17:27

- radom

- radom

Today 17:23

Replied by radom on topic DMU 50M retrofit 99% done, Z axis falling on brake release

DMU 50M retrofit 99% done, Z axis falling on brake release

Category: General LinuxCNC Questions

- Todd Zuercher

Today 17:15

- radom

- radom

Today 17:01

Replied by radom on topic DMU 50M retrofit 99% done, Z axis falling on brake release

DMU 50M retrofit 99% done, Z axis falling on brake release

Category: General LinuxCNC Questions

- tommylight

Today 16:56

- PCW

Today 16:43 - Today 17:13

- Todd Zuercher

Today 16:26

- PCW

Today 16:19

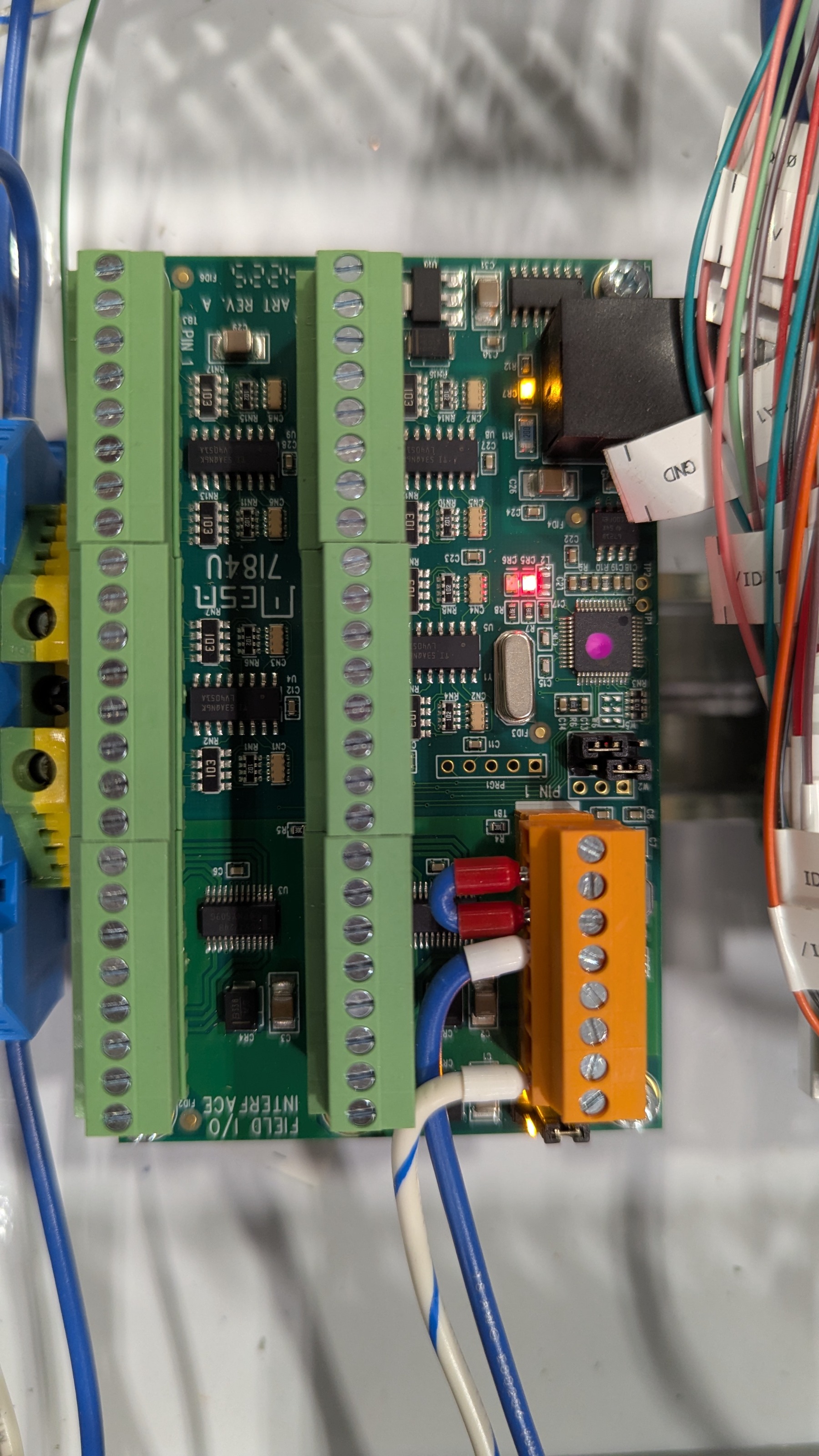

Replied by PCW on topic 7i92TM defect? How to verify?

7i92TM defect? How to verify?

Category: Driver Boards

Time to create page: 0.420 seconds