Search Results (Searched for: )

- andypugh

09 Apr 2025 13:40

Replied by andypugh on topic Weiler 160 CNC Retrofit

Weiler 160 CNC Retrofit

Category: Show Your Stuff

- my1987toyota

09 Apr 2025 13:23

Replied by my1987toyota on topic The dumification of humanity through internet

The dumification of humanity through internet

Category: Off Topic and Test Posts

- tommylight

09 Apr 2025 12:41

Replied by tommylight on topic The dumification of humanity through internet

The dumification of humanity through internet

Category: Off Topic and Test Posts

- tommylight

09 Apr 2025 12:38

Replied by tommylight on topic Firmware for 5i25

Firmware for 5i25

Category: General LinuxCNC Questions

- PCW

09 Apr 2025 12:34

- PCW

09 Apr 2025 12:25

- pgf

- pgf

09 Apr 2025 12:25

- my1987toyota

09 Apr 2025 11:50

Replied by my1987toyota on topic The dumification of humanity through internet

The dumification of humanity through internet

Category: Off Topic and Test Posts

- bevins

09 Apr 2025 11:50

- spumco

- spumco

09 Apr 2025 11:30

Replied by spumco on topic What do you really get for a $350 desk top engraver ?

What do you really get for a $350 desk top engraver ?

Category: Show Your Stuff

- JT

09 Apr 2025 11:26

- jenkinson8

- jenkinson8

09 Apr 2025 10:06

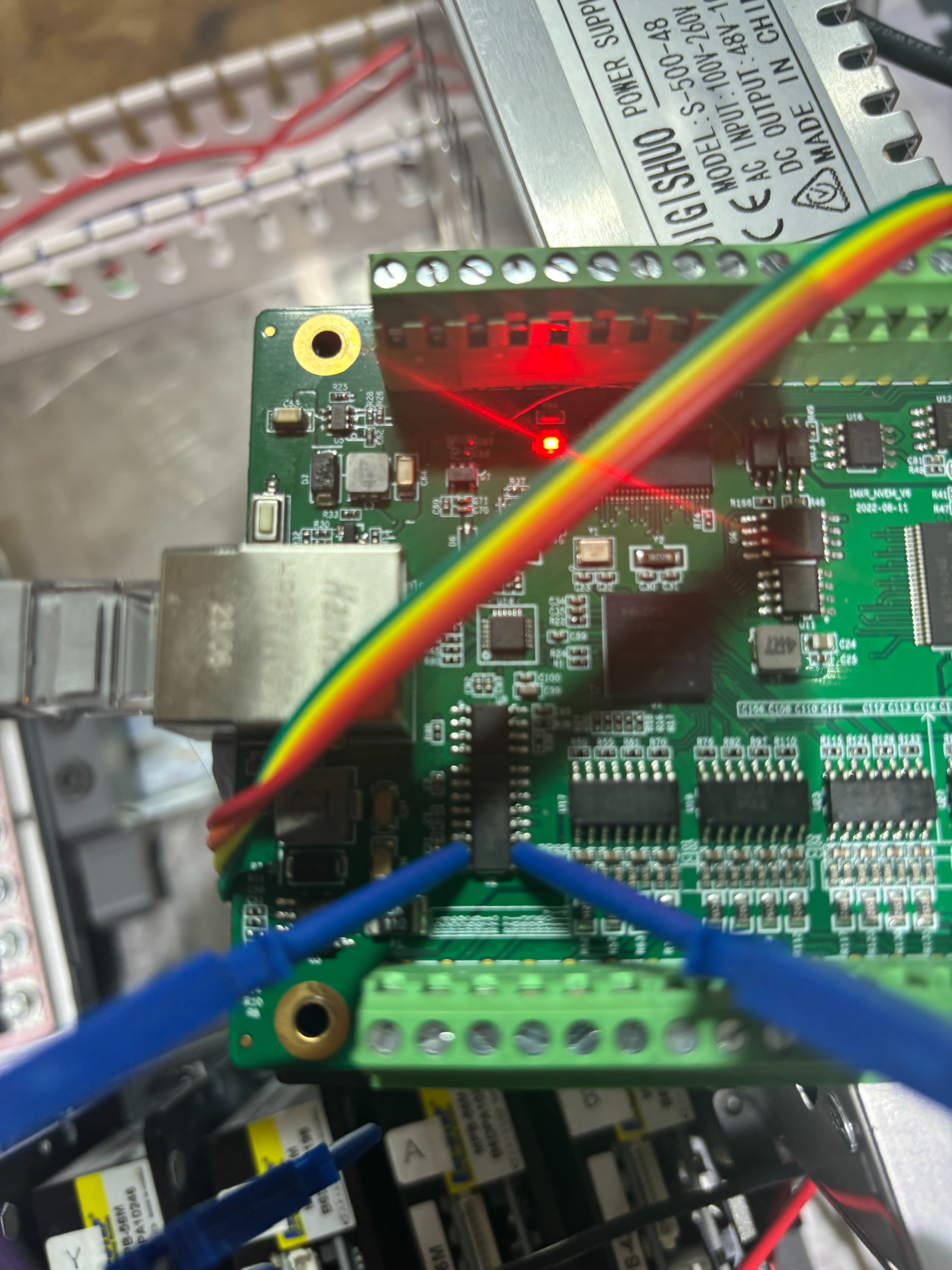

Replied by jenkinson8 on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- Boogie

- Boogie

09 Apr 2025 09:14

Replied by Boogie on topic ENCODER_RATIO function implementation.

ENCODER_RATIO function implementation.

Category: General LinuxCNC Questions

- Jan

- Jan

09 Apr 2025 08:41

Maschine only works in the Stepconf Wizard was created by Jan

Maschine only works in the Stepconf Wizard

Category: General LinuxCNC Questions

- snowgoer540

09 Apr 2025 08:29

Replied by snowgoer540 on topic Best cam software to use for plasma cutting

Best cam software to use for plasma cutting

Category: CAD CAM

Time to create page: 0.682 seconds