Search Results (Searched for: )

- papagno-source

- papagno-source

29 Mar 2025 12:34

- mclien

- mclien

29 Mar 2025 12:29

Replied by mclien on topic How to build a CNC Router?

How to build a CNC Router?

Category: Milling Machines

- Masiwood123

29 Mar 2025 12:27

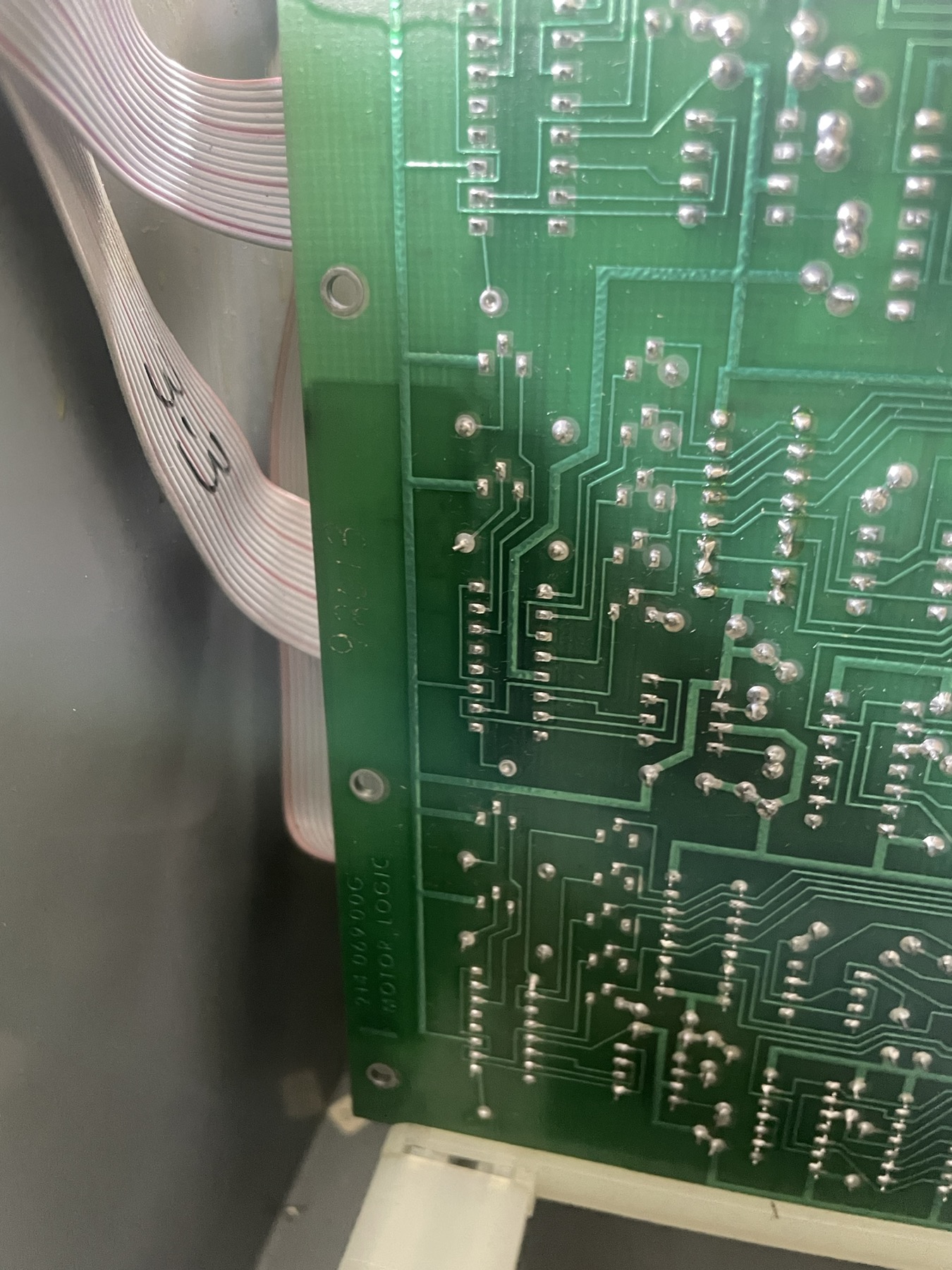

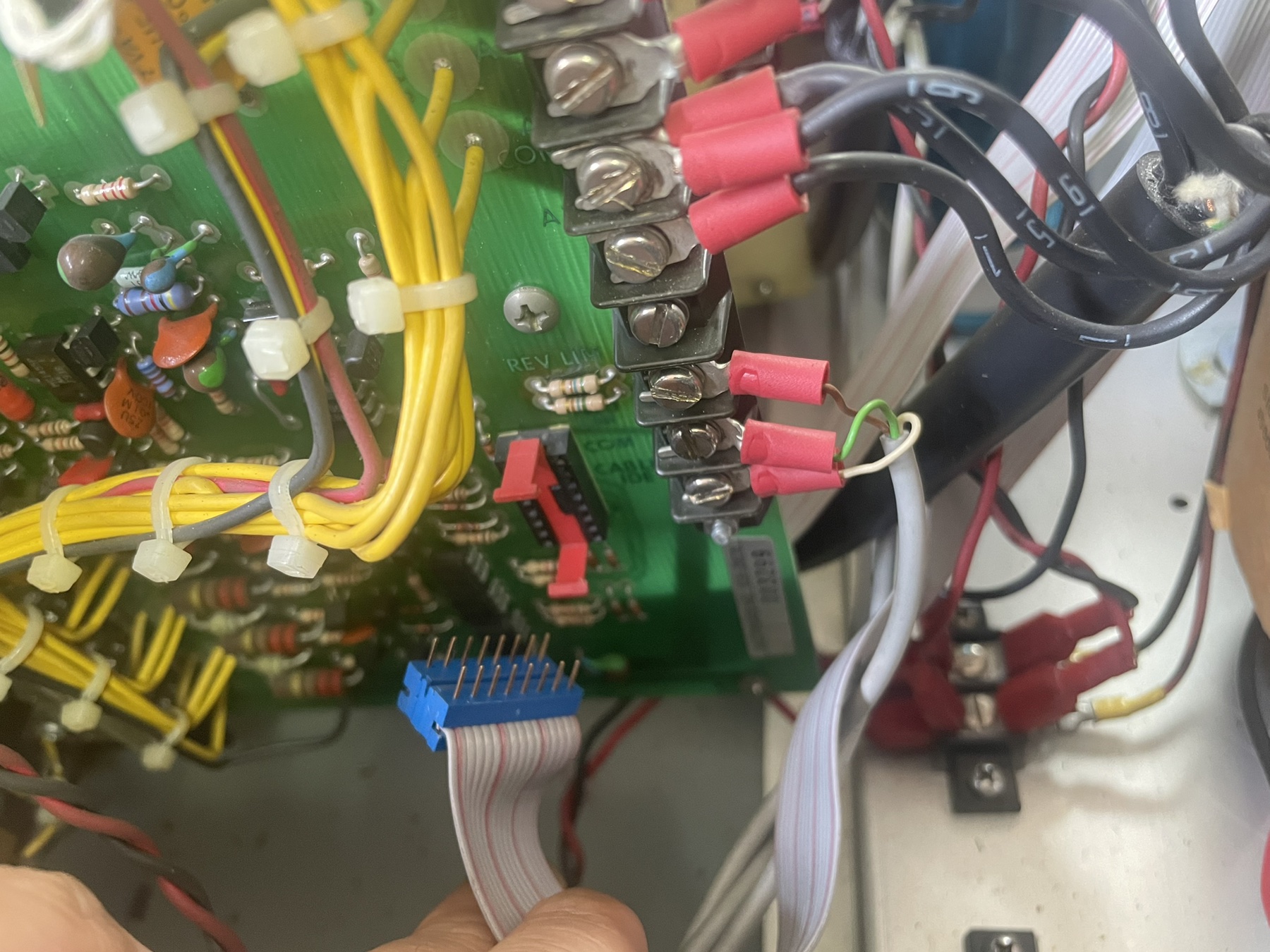

Replied by Masiwood123 on topic bandit controller retrofit

bandit controller retrofit

Category: General LinuxCNC Questions

- Grotius

29 Mar 2025 12:17

Replied by Grotius on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- rodw

29 Mar 2025 11:59 - 29 Mar 2025 12:00

Replied by rodw on topic Adding a M.2 ethernet port

Adding a M.2 ethernet port

Category: Computers and Hardware

- Grotius

29 Mar 2025 11:37 - 29 Mar 2025 11:46

Replied by Grotius on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- Domi

- Domi

29 Mar 2025 11:23

Replied by Domi on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- Hakan

- Hakan

29 Mar 2025 11:05 - 29 Mar 2025 11:32

Replied by Hakan on topic Adding a M.2 ethernet port

Adding a M.2 ethernet port

Category: Computers and Hardware

- Masiwood123

29 Mar 2025 10:24

Replied by Masiwood123 on topic bandit controller retrofit

bandit controller retrofit

Category: General LinuxCNC Questions

- machinedude

29 Mar 2025 09:50

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

What do you really get for a $350 desk top engraver ?

Category: Show Your Stuff

- rodw

29 Mar 2025 09:35

Replied by rodw on topic What do you really get for a $350 desk top engraver ?

What do you really get for a $350 desk top engraver ?

Category: Show Your Stuff

- machinedude

29 Mar 2025 09:21

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

What do you really get for a $350 desk top engraver ?

Category: Show Your Stuff

- rodw

29 Mar 2025 08:55

Replied by rodw on topic What do you really get for a $350 desk top engraver ?

What do you really get for a $350 desk top engraver ?

Category: Show Your Stuff

- rodw

29 Mar 2025 08:39

Replied by rodw on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- machinedude

29 Mar 2025 08:23

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

What do you really get for a $350 desk top engraver ?

Category: Show Your Stuff

Time to create page: 0.371 seconds