What do you really get for a $350 desk top engraver ?

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 Mar 2025 08:23 #325228

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

well i have my first real issue with this build. the X axis stepper tapped out on me today. to be fair i was giving it a workout as usual

the funny part is i made a video and got thought the first one fine but only made it halfway through the next one

I'm pretty sure i stripped something out on the internal parts of the motor which is a first for me. i guess if you mess around with this stuff long enough you run into just about everything

the funny part is i made a video and got thought the first one fine but only made it halfway through the next one

I'm pretty sure i stripped something out on the internal parts of the motor which is a first for me. i guess if you mess around with this stuff long enough you run into just about everything

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11668

- Thank you received: 3932

29 Mar 2025 08:55 #325230

by rodw

Replied by rodw on topic What do you really get for a $350 desk top engraver ?

Thats unusual. Usually, they overheat and loose steps if you push them too far and eventually stop. There isn't anything to strip really. But the temperature could exceed the safe limit and melt the insulation in the windings. What happens if you swap stepper drives?

There is something to be said for using quality motors. Try Moons Industries who you are in US.

There is something to be said for using quality motors. Try Moons Industries who you are in US.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 Mar 2025 09:21 #325231

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

it did seem odd to me too but i did a quick search on google on mechanical failures with steppers and it said gears stripping? i never tore one apart before but i might on this one just to see the inside. when you spin it by hand it feels wrong. usually, you can feel the 1.8-degree full steps.it turns under power but it has no torque.

i got a bigger one this time of the same brand because i can have it later today. my x was a bit under powered, so this is reason to bump up a little since i can get a 3 Nm with the same frame and shaft size.

i got a bigger one this time of the same brand because i can have it later today. my x was a bit under powered, so this is reason to bump up a little since i can get a 3 Nm with the same frame and shaft size.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11668

- Thank you received: 3932

29 Mar 2025 09:35 #325232

by rodw

Replied by rodw on topic What do you really get for a $350 desk top engraver ?

Great to see adoption of real engineering units in an imperial world!my x was a bit under powered, so this is reason to bump up a little since i can get a 3 Nm with the same frame and shaft size.

The following user(s) said Thank You: machinedude

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 Mar 2025 09:50 #325233

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

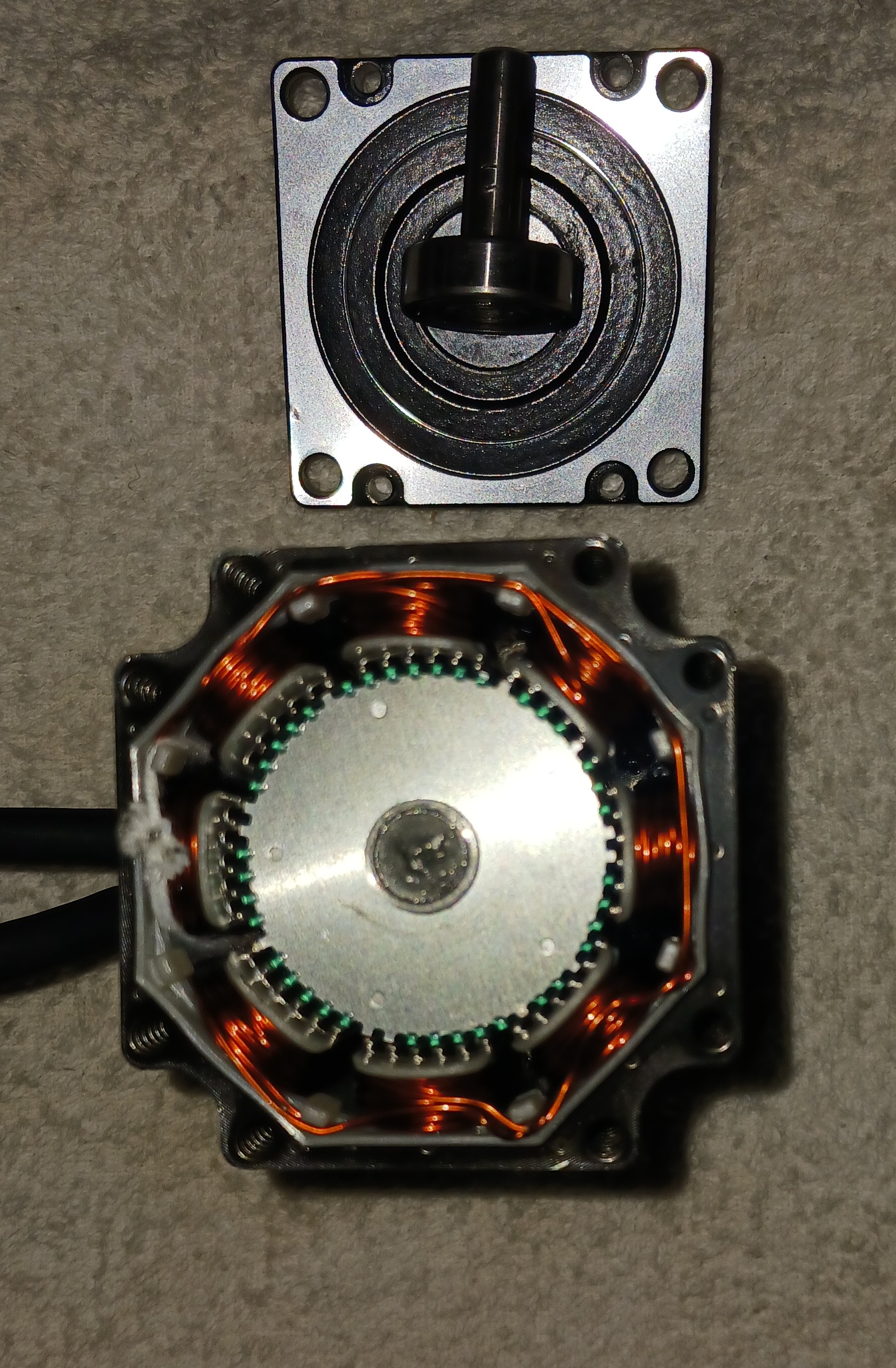

the end of the shaft snaped off. i just pulled it apart to see what i could find. that's pretty odd

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 Mar 2025 16:15 - 29 Mar 2025 16:16 #325258

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

Makes me wonder if this could have been my source of the surface finish issues i was chasing around before? to me it always seemed to be coming from this axis. it's almost looking like a material defect in the shaft material? it's hard to say for sure but i will keep an eye on my finishes to see if that gets better after a motor swap.

the shaft twisted off right behind the bearing. the whole thing came apart in two pieces with the end of the shaft and bearing in the end cap of the motor. no crashes so it seems odd on a 2 Nm motor i would guess it would stall before something this drastic would happen taking a guess.

the shaft twisted off right behind the bearing. the whole thing came apart in two pieces with the end of the shaft and bearing in the end cap of the motor. no crashes so it seems odd on a 2 Nm motor i would guess it would stall before something this drastic would happen taking a guess.

Attachments:

Last edit: 29 Mar 2025 16:16 by machinedude.

The following user(s) said Thank You: cakeslob

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11668

- Thank you received: 3932

30 Mar 2025 01:28 #325298

by rodw

Replied by rodw on topic What do you really get for a $350 desk top engraver ?

I said it was unusual. It had to be a flaw as you can stall a motor that size with your hand! First I've seen like that..

The following user(s) said Thank You: machinedude

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21230

- Thank you received: 7249

30 Mar 2025 01:59 #325299

by tommylight

Replied by tommylight on topic What do you really get for a $350 desk top engraver ?

I've seen those before but not on such a small size motor, that always happens when the shaft is mounted crooked as all motors have a pretty low "side load" value for shafts.

Having said all that, shafts bend almost always, very rare occasions of them braking.

This on the other hand seems it was put under to much stress when inserting the metal plates as it sheared clean off, so i would venture a guess that it was already cracked, can be seen by the discoloration, although might be from the low quality picture.

Having said all that, shafts bend almost always, very rare occasions of them braking.

This on the other hand seems it was put under to much stress when inserting the metal plates as it sheared clean off, so i would venture a guess that it was already cracked, can be seen by the discoloration, although might be from the low quality picture.

The following user(s) said Thank You: machinedude

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

30 Mar 2025 02:44 - 30 Mar 2025 02:45 #325300

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

when i first built the machine my finishes looked like they were almost perfect and as time went on it settled into something i noticed and I messed around with for a while.

then i got sidetracked when i started thinking plasma machine and am just now coming back to deal with it

new motor is here already and am now working on getting that put on. i just thought it was interesting since i never seen this happen before. hopefully the new motor fixes everything. unplanned upgrade at this point

then i got sidetracked when i started thinking plasma machine and am just now coming back to deal with it

new motor is here already and am now working on getting that put on. i just thought it was interesting since i never seen this happen before. hopefully the new motor fixes everything. unplanned upgrade at this point

Last edit: 30 Mar 2025 02:45 by machinedude.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

30 Mar 2025 12:29 #325318

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

huge difference with surface finish with a less than perfect tool path and part for a machine this size.

Machinedude does his happy dance

Machinedude does his happy dance

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

Time to create page: 0.125 seconds