What do you really get for a $350 desk top engraver ?

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

19 Dec 2023 06:09 #288547

by machinedude

What do you really get for a $350 desk top engraver ? was created by machinedude

So i got curious and took a deep dive into how and why all these imports are so cheap  some things i liked and a lot of stuff i don't like so here i am not able to leave well enough alone.

some things i liked and a lot of stuff i don't like so here i am not able to leave well enough alone.

i wanted to do something simple with linux cnc as a first project to get my feet wet since i have been in limbo for a while with the pandemic turning everything upside down for a while and my kids needing bailed out every time i turn around things seem to be back to normal for the most part now

things seem to be back to normal for the most part now

The stock machine came with a Grbl controller and Candle software which is beyond basic. the stock table top was MDF and that was the first thing to get replaced. i had some 25mm x 75mm t slot extrusion on the shelf so it found a new home. i thought the 25mm x 75mm extrusion was light at the time and never used it. what is really light is the 3D printer extrusion on this machine and that is getting replaced soon.

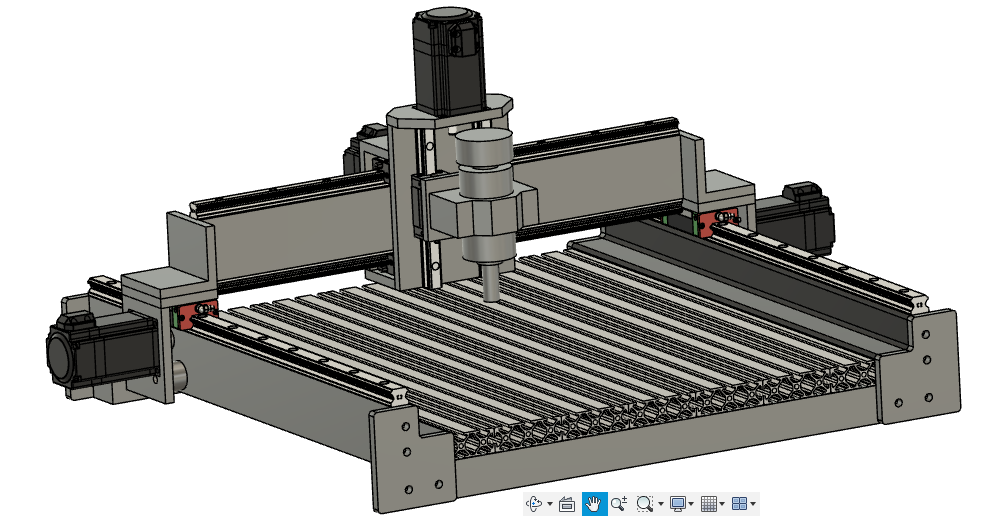

Over the last week or so i have been gathering bits and pieces and for the last few days i have been working on the design for a better foundation to build from. here is what i have so far just for visual reference. if i get smart about limit switches and belt tension i actually will pick up over 4" of travel on the Y axis so that is a plus at least should be around 16" x 20 " packed in a 600mm x 600mm foot print.

should be around 16" x 20 " packed in a 600mm x 600mm foot print.

i wanted to do something simple with linux cnc as a first project to get my feet wet since i have been in limbo for a while with the pandemic turning everything upside down for a while and my kids needing bailed out every time i turn around

The stock machine came with a Grbl controller and Candle software which is beyond basic. the stock table top was MDF and that was the first thing to get replaced. i had some 25mm x 75mm t slot extrusion on the shelf so it found a new home. i thought the 25mm x 75mm extrusion was light at the time and never used it. what is really light is the 3D printer extrusion on this machine and that is getting replaced soon.

Over the last week or so i have been gathering bits and pieces and for the last few days i have been working on the design for a better foundation to build from. here is what i have so far just for visual reference. if i get smart about limit switches and belt tension i actually will pick up over 4" of travel on the Y axis so that is a plus at least

Attachments:

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

19 Dec 2023 23:00 #288624

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

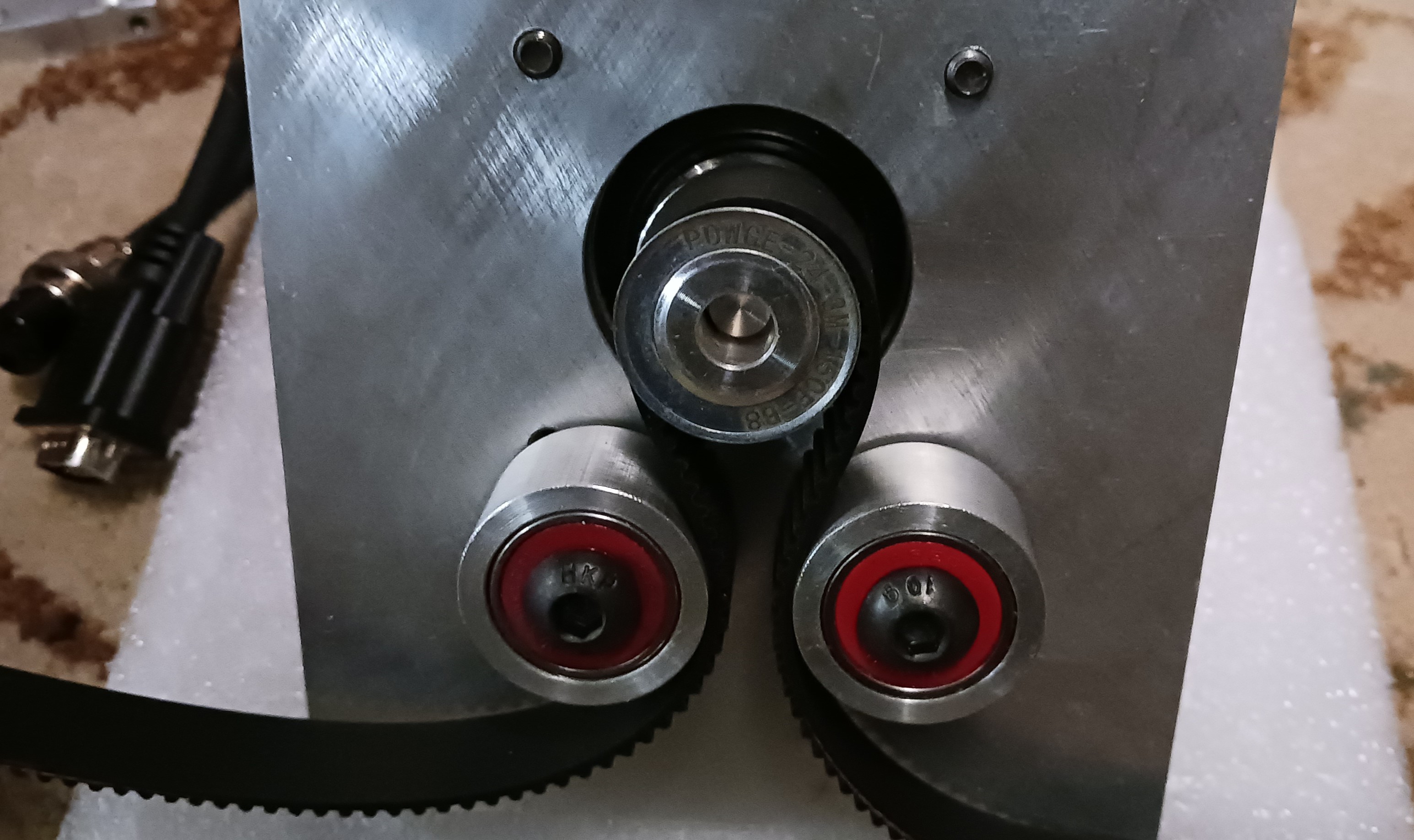

Santa came early this year  4 motors and drives with 2 power supplies plus a 7I96S that came yesterday

4 motors and drives with 2 power supplies plus a 7I96S that came yesterday

on a side note the original machine has the option for a laser so once i get the new frame done for the spindle that's most likely the direction the things will end up going when I'm done with this.

on a side note the original machine has the option for a laser so once i get the new frame done for the spindle that's most likely the direction the things will end up going when I'm done with this.

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Cant do this anymore bye all

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1200

- Thank you received: 425

20 Dec 2023 08:23 #288653

by Cant do this anymore bye all

Replied by Cant do this anymore bye all on topic What do you really get for a $350 desk top engraver ?

Myfordboy did a bit of work on a cheap one a few years ago, not so big but kinda similar project, similar not as involved.

www.youtube.com/playlist?list=PLHUJDLlTM...R4jF0rJAO8ySmhwsysRD

www.youtube.com/playlist?list=PLHUJDLlTM...R4jF0rJAO8ySmhwsysRD

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

20 Dec 2023 09:58 #288658

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

with the exception of the v rollers in the extrusion t slots and the mdf top the machine is well designed. the z axis would be the only linear rails on the original machine. i did circle mill the t slot table i added but took it slow an easy. it did good believe it or not  but it took a long time.

but it took a long time.

this machine came with a 300 watt spindle and runs at 10,000 rpm and is not that bad and was one of the few things i liked. but with the current set up you can not even get close to getting what you can from this spindle.

i don't have any hopes of running it at anything less than wide open so soft material is all i am looking for at high feed rates.right now i would not even try anything more than a 1/8 end mill and a 1/4 is the max with the ER 11 collets.

this machine came with a 300 watt spindle and runs at 10,000 rpm and is not that bad and was one of the few things i liked. but with the current set up you can not even get close to getting what you can from this spindle.

i don't have any hopes of running it at anything less than wide open so soft material is all i am looking for at high feed rates.right now i would not even try anything more than a 1/8 end mill and a 1/4 is the max with the ER 11 collets.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

22 Dec 2023 09:39 #288816

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

It sure would be nice to get my open ended belt early  it's in the tracking system here. and the estimated delivery date was Jan 4th.

it's in the tracking system here. and the estimated delivery date was Jan 4th.

I have 4 days off and plan on doing a bunch and that would just be sweet if that showed up before Christmas

I have 4 days off and plan on doing a bunch and that would just be sweet if that showed up before Christmas

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

27 Dec 2023 05:22 #289144

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

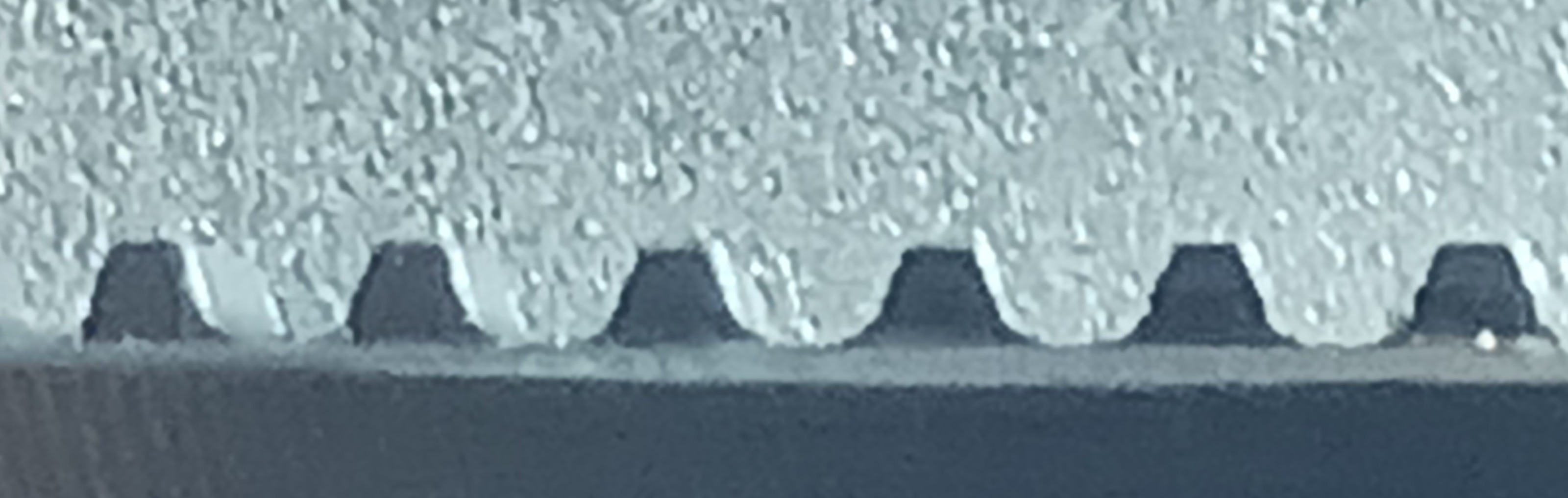

well no belts before Christmas but they did come on the 26th which is way ahead of the Jan 4th date. However they are not steel corded like i thought? i guess i will have to use them and see how well they do? they look like they are well made so time will tell i guess.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

28 Dec 2023 15:25 #289254

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

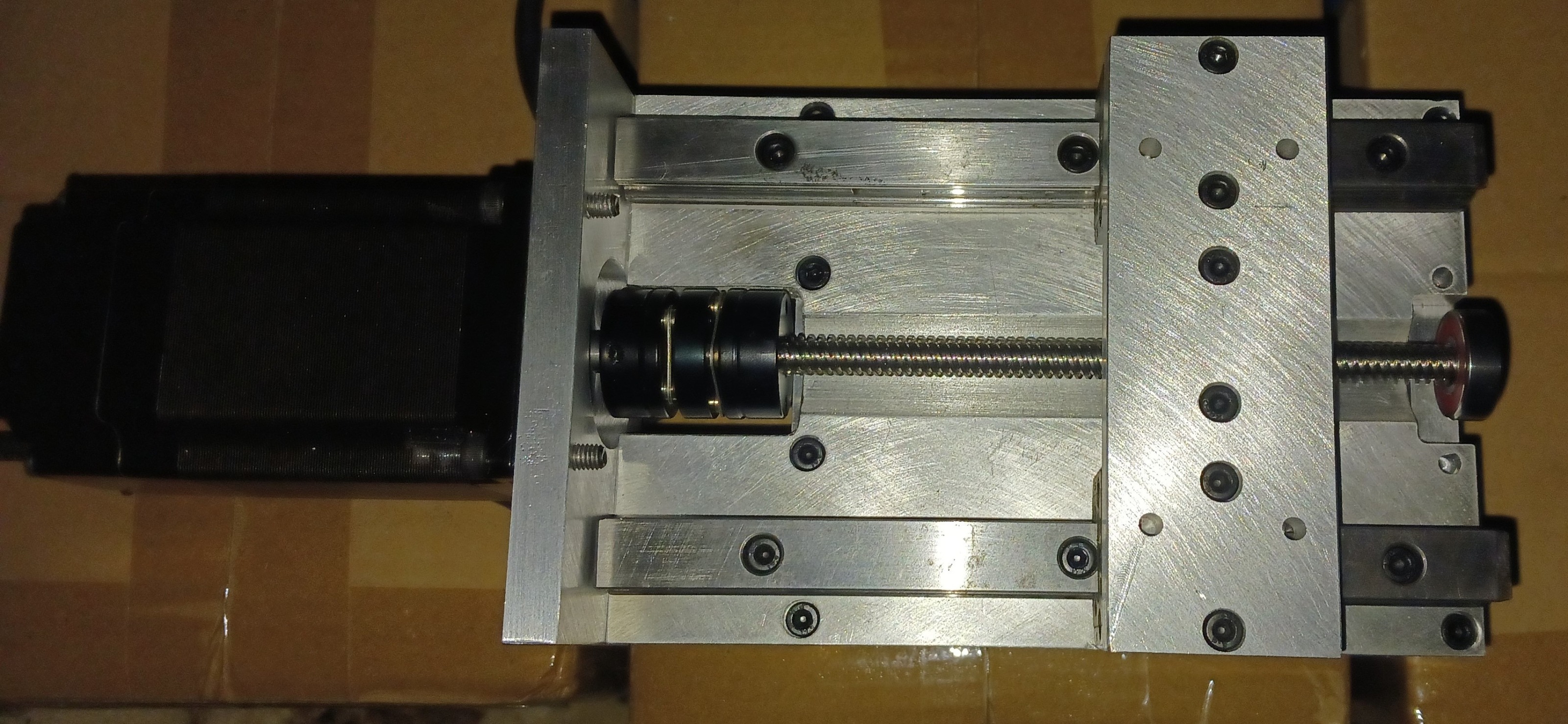

bits and pieces of odds and ends mostly from past projects but the start of something here  making parts on this thing as it is now is like trying to dig a ditch with a spoon

making parts on this thing as it is now is like trying to dig a ditch with a spoon  at least i will have a base line to gauge from to see how much better it gets

at least i will have a base line to gauge from to see how much better it gets  the old linear rails i had laying around were actually lower profile so fitting a screw under took some sorting out.

the old linear rails i had laying around were actually lower profile so fitting a screw under took some sorting out.

Attachments:

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

31 Dec 2023 09:50 - 31 Dec 2023 09:56 #289422

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

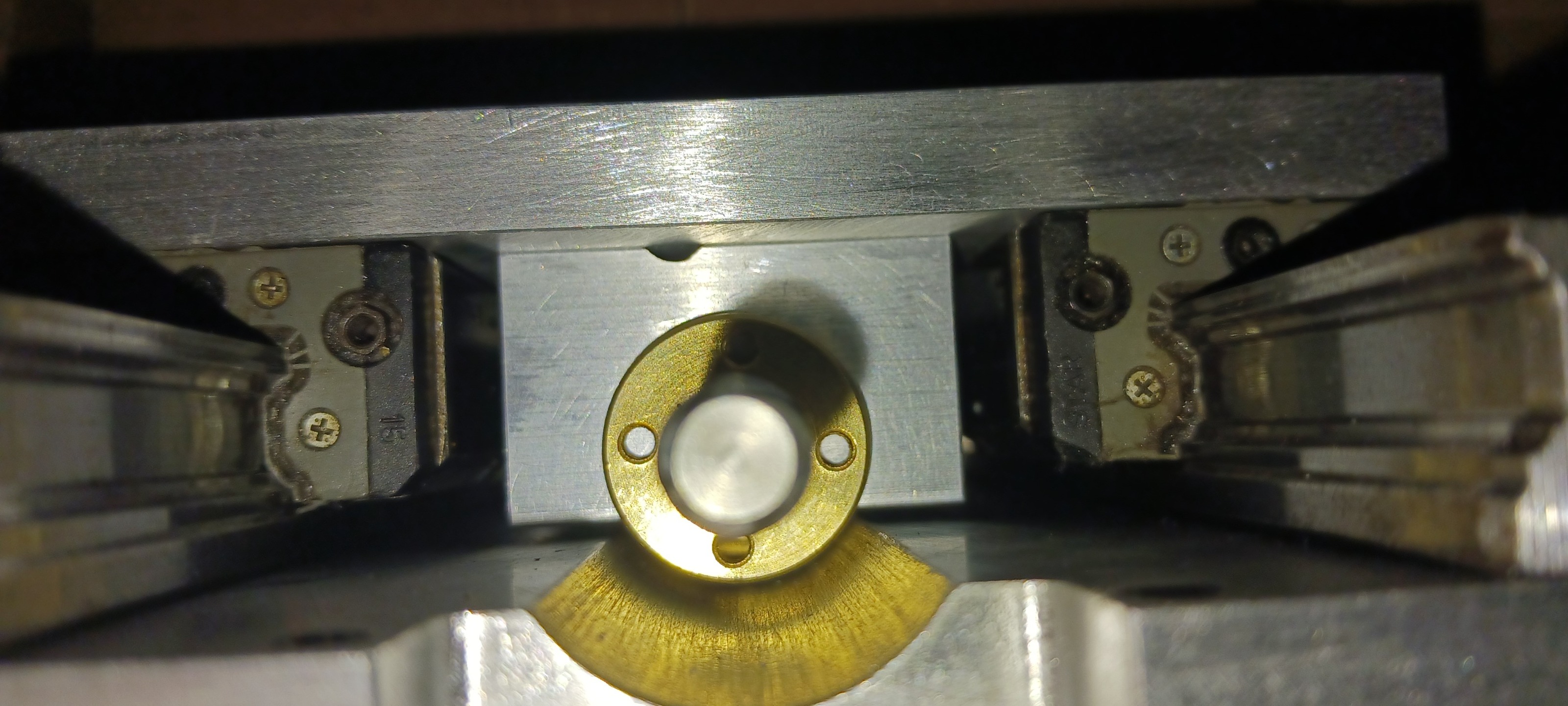

I still have a few small things to finish on my Z axis but i made some progress on it and you can start to see how it all comes together now. Where i had to set the motor so the spindle clears on retraction created some fit issues on the screw section. I have to modify the brass nut flanges but am running double nuts to deal with backlash. 8mm screw with 8mm lead but they are under 6 inches in total length so it should work fine here. I also had to cut out around the coupler to make room as well and had to do a recessed bearing block just to get a bearing on the right center line for the whole assembly. Needless to so things are pretty tight around the screw assembly I think the one picture shows it well. from the top of the bearing blocks to the base plate is only 24mm and the flange on the brass nuts are 22mm in diameter so a tight fit to say the least

Attachments:

Last edit: 31 Dec 2023 09:56 by machinedude.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

07 Jan 2024 13:00 #290086

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

15 Jan 2024 05:34 #290732

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.219 seconds