What do you really get for a $350 desk top engraver ?

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

08 Sep 2024 11:10 #309644

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

the belts i am using don't have much backlash if any. Planetary gear boxes have some backlash to them and they require some space. i agree you can get some cheap gear boxes out of China even a small harmonic is not too bad in price but require the extra space. if you were needing loads of torque a harmonic drive would be the way to go but i noticed the life on the cheap ones is only 6000 or 7000 hours.

Belts are dirt cheap i would have to price around but you can even get pulley stock with the teeth cut if you don't want to get into doing that part and want to do some custom pulley ideas.

i would have to price around but you can even get pulley stock with the teeth cut if you don't want to get into doing that part and want to do some custom pulley ideas.

Belts are dirt cheap

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

08 Sep 2024 12:02 #309650

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

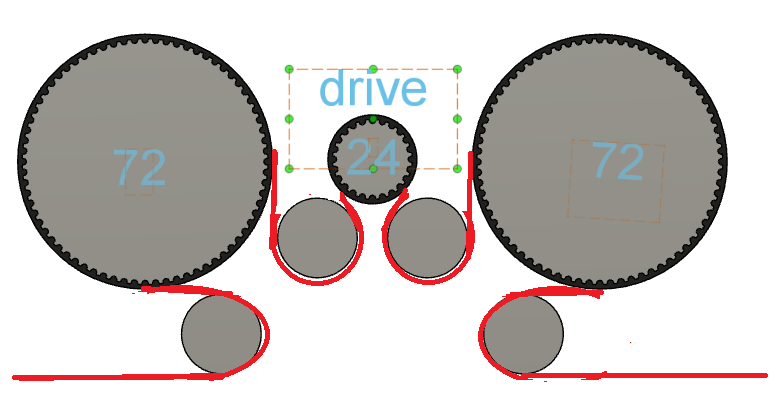

this is just a very crude picture of the belt route and gears for a linear reduction for open ended belts. the 72 tooth pulley's would just be a toothed idler pulley for the reduction and the idlers are for the omega configuration to route the belt out of the serpentine. the motor for the drive would just be mounted on the back side of a plate that holds everything in place.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21216

- Thank you received: 7246

08 Sep 2024 13:05 #309652

by tommylight

Replied by tommylight on topic What do you really get for a $350 desk top engraver ?

Hmmmm something very wrong with that picture,

-if there is a single belt used and the red lines are also that belt, it will not reduce anything at all

-if there are more belts in use, again it just seems to much parts and effort for nothing

-if there is friction used somewhere (black belts only on pulleys???) again no use for two sets of everything

-if there is a single belt used and the red lines are also that belt, it will not reduce anything at all

-if there are more belts in use, again it just seems to much parts and effort for nothing

-if there is friction used somewhere (black belts only on pulleys???) again no use for two sets of everything

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

08 Sep 2024 14:00 #309655

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

no the black is just a reference for the belt thickness i was not even going to try to draw teeth on everything. It was was just an idea and i will probably test it just because it gives me something to do  if nothing else you end up with a lot more surface contact engaged into the belt. Which i think is my man issue for a solution.

if nothing else you end up with a lot more surface contact engaged into the belt. Which i think is my man issue for a solution.

i look at things differently i had no idea how to model a arc tooth pulley before and now i do so i learned something so if you learn something it's not a total loss.

so if you learn something it's not a total loss.

i look at things differently i had no idea how to model a arc tooth pulley before and now i do so i learned something

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21216

- Thank you received: 7246

08 Sep 2024 14:49 #309667

by tommylight

Replied by tommylight on topic What do you really get for a $350 desk top engraver ?

Keep on chugging along, utmost respect for your persistence and effort.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

08 Sep 2024 16:58 #309681

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

this is why i got the 3d printer to test stuff and not spend much money on idea's  i probably have OCD

i probably have OCD  i have to see stuff with my own eyes before i give up on anything

i have to see stuff with my own eyes before i give up on anything  i share the good bad and the ugly regardless of outcome

i share the good bad and the ugly regardless of outcome

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1973

- Thank you received: 807

08 Sep 2024 17:16 #309683

by spumco

Replied by spumco on topic What do you really get for a $350 desk top engraver ?

The Bell-Everman drive is a nice system, but you need to put any reduction upstream/ahead of the pinion. As Tommy pointed out the 72T idlers won't reduce anything.

A low-backlash, helical gear reducer between the motor and the pinion is the way to go.

And if you've got the space for some extra carriage length, the 'Loop-track' system brom B-E is really nice.

A low-backlash, helical gear reducer between the motor and the pinion is the way to go.

And if you've got the space for some extra carriage length, the 'Loop-track' system brom B-E is really nice.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1973

- Thank you received: 807

08 Sep 2024 17:20 - 08 Sep 2024 17:24 #309686

by spumco

Replied by spumco on topic What do you really get for a $350 desk top engraver ?

Like this one I built for a couple of plasma tables.

In these photos the motor is mocked up directly on the pinion, but we wound up using a 10:1 reducer between the motor and pinion.

Belt was T5, pinion was 15T (bought T5 15T bar stock). Mr. Everman pointed out on CNCZone years ago that only T-series belt teeth/valleys are symmetrical - HTD and GT2/GT3 have non-meshing teeth.

In these photos the motor is mocked up directly on the pinion, but we wound up using a 10:1 reducer between the motor and pinion.

Belt was T5, pinion was 15T (bought T5 15T bar stock). Mr. Everman pointed out on CNCZone years ago that only T-series belt teeth/valleys are symmetrical - HTD and GT2/GT3 have non-meshing teeth.

Last edit: 08 Sep 2024 17:24 by spumco.

The following user(s) said Thank You: tommylight, Aciera

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

09 Sep 2024 07:12 #309714

by machinedude

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

the biggest problem is the machine is built already and space is limited. if i could do any kind of reduction it would probably have to hang out to the side but if i could come up with a way now i know i can put whatever size on the open loop side and increase the circumference to get more engagement. i think the belt is compressing under load with a tiny 24 tooth pulley. so if it is doing it on the open loop belt side a bigger set on the other side would be a good idea too i think if it's even possible my fear is i painted myself into a corner

i will have to dig some more and look at the stuff you suggested in more depth thanks for the feedback

straight cuts work just fine but cutting a contour is where things get weird shows up looking like chatter when trying to finish. it is so close to being there but needs a little help to get that little extra bit of stiffness needed

i will have to dig some more and look at the stuff you suggested in more depth thanks for the feedback

straight cuts work just fine but cutting a contour is where things get weird shows up looking like chatter when trying to finish. it is so close to being there but needs a little help to get that little extra bit of stiffness needed

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11657

- Thank you received: 3924

09 Sep 2024 08:17 #309718

by rodw

Replied by rodw on topic What do you really get for a $350 desk top engraver ?

It is possible to build a belt driven reduction that mounts in place of a NEMA23 motor. I did it here (but using a pinion.)

forum.linuxcnc.org/30-cnc-machines/31509...inion-drive?start=20

forum.linuxcnc.org/30-cnc-machines/31509...inion-drive?start=20

Please Log in or Create an account to join the conversation.

Time to create page: 0.100 seconds