Search Results (Searched for: )

- Todd Zuercher

10 Dec 2024 18:49

Replied by Todd Zuercher on topic FreeCAD 1.0 Who's using it?

FreeCAD 1.0 Who's using it?

Category: CAD CAM

- TooTall18T

10 Dec 2024 18:44 - 24 Feb 2025 19:15

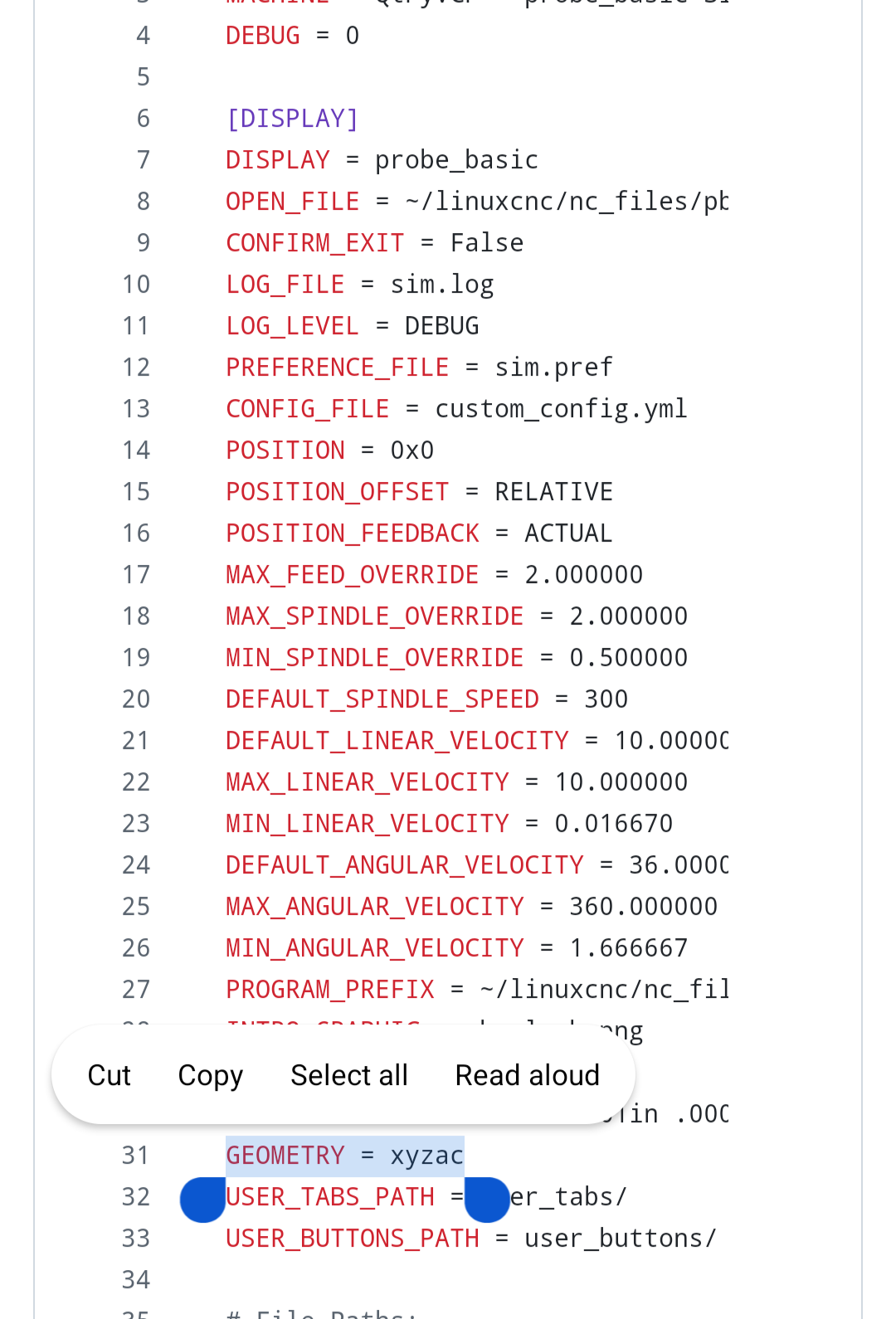

Replied by TooTall18T on topic tool length probe subroutine for Probe Basic

tool length probe subroutine for Probe Basic

Category: Mill Library

- schuetzbuilds

- schuetzbuilds

10 Dec 2024 18:23

Replied by schuetzbuilds on topic Retrofitting a MAHO MH600T

Retrofitting a MAHO MH600T

Category: Milling Machines

- CNC_ANDI

- CNC_ANDI

10 Dec 2024 18:02

- fully_defined

10 Dec 2024 17:05

Replied by fully_defined on topic Rotary Selector Switches & Resistors

Rotary Selector Switches & Resistors

Category: General LinuxCNC Questions

- PCW

10 Dec 2024 16:32 - 10 Dec 2024 16:37

Replied by PCW on topic Rotary Selector Switches & Resistors

Rotary Selector Switches & Resistors

Category: General LinuxCNC Questions

- Lcvette

10 Dec 2024 16:29 - 10 Dec 2024 16:30

- tommylight

10 Dec 2024 16:04

Replied by tommylight on topic Rotary Selector Switches & Resistors

Rotary Selector Switches & Resistors

Category: General LinuxCNC Questions

- hans48

- hans48

10 Dec 2024 15:53

- fully_defined

10 Dec 2024 15:53

Replied by fully_defined on topic Rotary Selector Switches & Resistors

Rotary Selector Switches & Resistors

Category: General LinuxCNC Questions

- Uthayne

- Uthayne

10 Dec 2024 15:10 - 10 Dec 2024 15:11

Replied by Uthayne on topic Cut Recovery Not Consistently Triggering

Cut Recovery Not Consistently Triggering

Category: Plasmac

- Wrightys99

- Wrightys99

10 Dec 2024 13:54

Replied by Wrightys99 on topic How to build a spaceship with Linuxcnc and a Mesa 7i76e

How to build a spaceship with Linuxcnc and a Mesa 7i76e

Category: Basic Configuration

- Hossein74Majidi

- Hossein74Majidi

10 Dec 2024 12:28

Replied by Hossein74Majidi on topic Real-Time Kernel with Orange Pi 4 LTS

Real-Time Kernel with Orange Pi 4 LTS

Category: General LinuxCNC Questions

- meister

- meister

10 Dec 2024 12:23

- my1987toyota

10 Dec 2024 11:28

Replied by my1987toyota on topic FreeCAD 1.0 Who's using it?

FreeCAD 1.0 Who's using it?

Category: CAD CAM

Time to create page: 0.421 seconds