Search Results (Searched for: )

- PCW

15 Dec 2025 16:54

- langdons

15 Dec 2025 16:25

Replied by langdons on topic Avon 3000 Mill retrofit

Avon 3000 Mill retrofit

Category: Milling Machines

- Aciera

15 Dec 2025 15:50

Replied by Aciera on topic VOLATILE_HOME not unhoming on fault

VOLATILE_HOME not unhoming on fault

Category: Basic Configuration

- jaro_p

15 Dec 2025 14:44

Replied by jaro_p on topic Changes in configuration files generated in pncconfig for 7i76 to 7i78

Changes in configuration files generated in pncconfig for 7i76 to 7i78

Category: PnCConf Wizard

- tommylight

15 Dec 2025 14:22

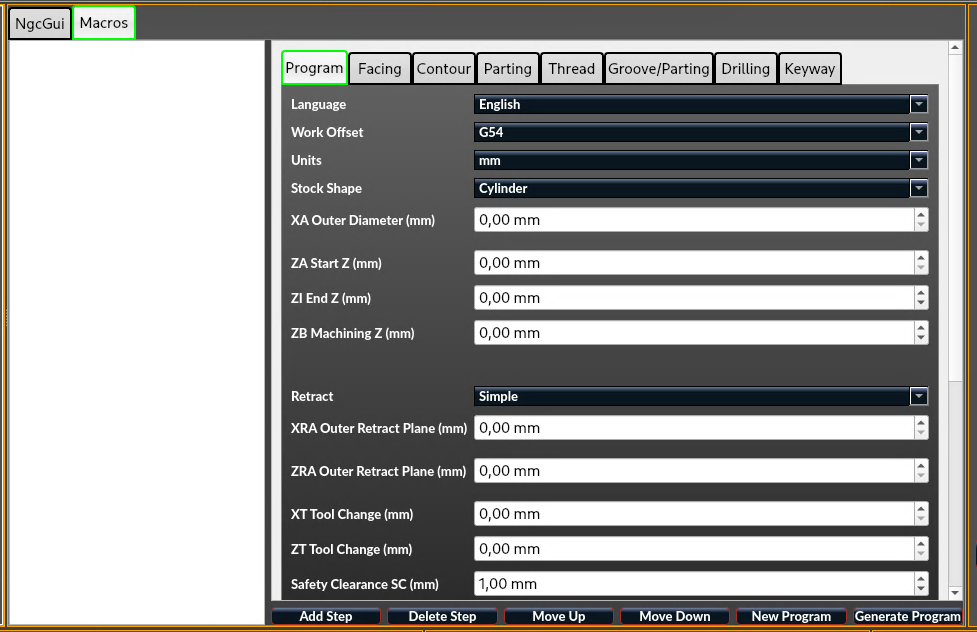

Replied by tommylight on topic LatheEasyStep – experimental QtVCP macro for step-by-step lathe programming

LatheEasyStep – experimental QtVCP macro for step-by-step lathe programming

Category: Qtvcp

- aDm1N

15 Dec 2025 14:15

- cmorley

- cmorley

15 Dec 2025 13:53

Replied by cmorley on topic LatheEasyStep – experimental QtVCP macro for step-by-step lathe programming

LatheEasyStep – experimental QtVCP macro for step-by-step lathe programming

Category: Qtvcp

- tommylight

15 Dec 2025 13:44

Replied by tommylight on topic VOLATILE_HOME not unhoming on fault

VOLATILE_HOME not unhoming on fault

Category: Basic Configuration

- Aciera

15 Dec 2025 13:41

Replied by Aciera on topic VOLATILE_HOME not unhoming on fault

VOLATILE_HOME not unhoming on fault

Category: Basic Configuration

- Murphy

- Murphy

15 Dec 2025 13:33 - 15 Dec 2025 13:33

Replied by Murphy on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- aDm1N

15 Dec 2025 12:19 - 15 Dec 2025 12:51

- zoeper

- zoeper

15 Dec 2025 10:53 - 15 Dec 2025 11:10

Replied by zoeper on topic Avon 3000 Mill retrofit

Avon 3000 Mill retrofit

Category: Milling Machines

- tommylight

15 Dec 2025 10:43

Replied by tommylight on topic Updating from LINUXCNC - 2.8.4-23, Mint 20.3 - gmoccapy lathe structure

Updating from LINUXCNC - 2.8.4-23, Mint 20.3 - gmoccapy lathe structure

Category: Gmoccapy

- rodw

15 Dec 2025 10:22

Replied by rodw on topic Axis deflecting while jogging in G54

Axis deflecting while jogging in G54

Category: QtPyVCP

- rodw

15 Dec 2025 10:19

Replied by rodw on topic Long initialization of Ethercat on servo drive SV660N

Long initialization of Ethercat on servo drive SV660N

Category: EtherCAT

Time to create page: 0.257 seconds