Search Results (Searched for: )

- TimP

- TimP

21 Nov 2025 12:12

Replied by TimP on topic Need your opinion on Axes placement.

Need your opinion on Axes placement.

Category: CNC Machines

- Mr. Mass

21 Nov 2025 12:09

- snowgoer540

21 Nov 2025 12:06

Replied by snowgoer540 on topic How do you vote in the hardware survey?

How do you vote in the hardware survey?

Category: General LinuxCNC Questions

- abs32

- abs32

21 Nov 2025 11:43 - 23 Nov 2025 16:16

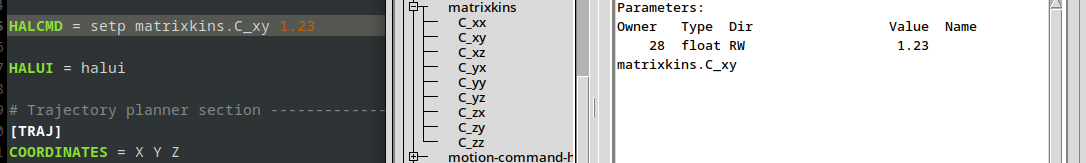

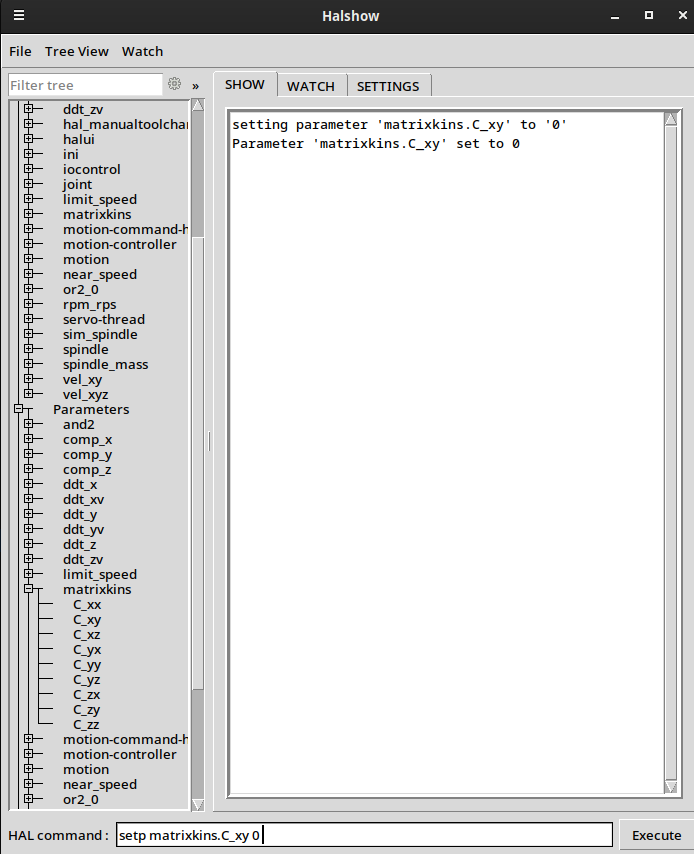

Replied by abs32 on topic v2.9 and not the perpendicularity of X and Y

v2.9 and not the perpendicularity of X and Y

Category: General LinuxCNC Questions

- Aciera

21 Nov 2025 10:28

Replied by Aciera on topic v2.9 and not the perpendicularity of X and Y

v2.9 and not the perpendicularity of X and Y

Category: General LinuxCNC Questions

- abs32

- abs32

21 Nov 2025 10:20 - 21 Nov 2025 10:21

Replied by abs32 on topic v2.9 and not the perpendicularity of X and Y

v2.9 and not the perpendicularity of X and Y

Category: General LinuxCNC Questions

- abs32

- abs32

21 Nov 2025 10:13 - 21 Nov 2025 10:16

Replied by abs32 on topic v2.9 and not the perpendicularity of X and Y

v2.9 and not the perpendicularity of X and Y

Category: General LinuxCNC Questions

- abs32

- abs32

21 Nov 2025 10:09

Replied by abs32 on topic v2.9 and not the perpendicularity of X and Y

v2.9 and not the perpendicularity of X and Y

Category: General LinuxCNC Questions

- Aciera

21 Nov 2025 09:52

Replied by Aciera on topic v2.9 and not the perpendicularity of X and Y

v2.9 and not the perpendicularity of X and Y

Category: General LinuxCNC Questions

- abs32

- abs32

21 Nov 2025 09:42 - 21 Nov 2025 09:43

Replied by abs32 on topic v2.9 and not the perpendicularity of X and Y

v2.9 and not the perpendicularity of X and Y

Category: General LinuxCNC Questions

- Aciera

21 Nov 2025 09:25

Replied by Aciera on topic v2.9 and not the perpendicularity of X and Y

v2.9 and not the perpendicularity of X and Y

Category: General LinuxCNC Questions

- abs32

- abs32

21 Nov 2025 09:21 - 21 Nov 2025 09:21

Replied by abs32 on topic v2.9 and not the perpendicularity of X and Y

v2.9 and not the perpendicularity of X and Y

Category: General LinuxCNC Questions

- dgdodo

- dgdodo

21 Nov 2025 09:19

Replied by dgdodo on topic [SOLVED] Backlash issues on Y-AXIS

[SOLVED] Backlash issues on Y-AXIS

Category: Advanced Configuration

- Aciera

21 Nov 2025 09:17

Replied by Aciera on topic v2.9 and not the perpendicularity of X and Y

v2.9 and not the perpendicularity of X and Y

Category: General LinuxCNC Questions

- viacolvento

- viacolvento

21 Nov 2025 08:52

Replied by viacolvento on topic Funzioni pausa e resume con pulsanti esterni.

Funzioni pausa e resume con pulsanti esterni.

Category: HAL

Time to create page: 0.237 seconds