Search Results (Searched for: )

- skyguybrad

- skyguybrad

13 Nov 2025 04:28

pulling my hair out please help was created by skyguybrad

pulling my hair out please help

Category: Basic Configuration

- tommylight

13 Nov 2025 02:14

Replied by tommylight on topic qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

Category: Qtvcp

- EDesro

- EDesro

13 Nov 2025 01:37

Replied by EDesro on topic qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

Category: Qtvcp

- tommylight

13 Nov 2025 01:14

Replied by tommylight on topic Avon 3000 Mill retrofit

Avon 3000 Mill retrofit

Category: Milling Machines

- CaliusOptimus

- CaliusOptimus

12 Nov 2025 22:49

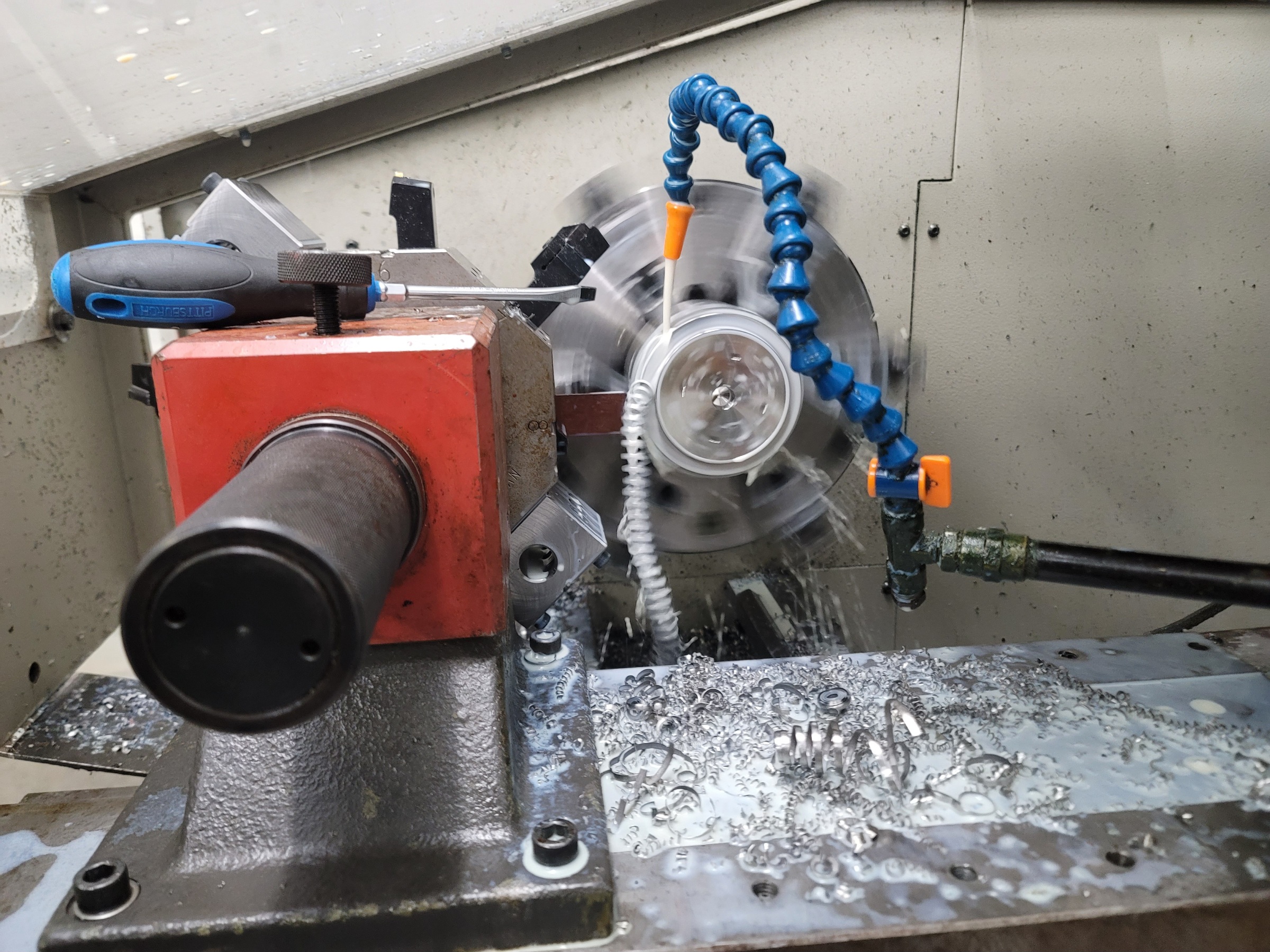

Replied by CaliusOptimus on topic Lathe project needs a turret

Lathe project needs a turret

Category: Turning

- Hakan

- Hakan

12 Nov 2025 22:41 - 12 Nov 2025 23:00

Replied by Hakan on topic Configuration Schnider electric ILA2 Servo

Configuration Schnider electric ILA2 Servo

Category: EtherCAT

- zoeper

- zoeper

12 Nov 2025 22:17

Replied by zoeper on topic Avon 3000 Mill retrofit

Avon 3000 Mill retrofit

Category: Milling Machines

- unknown

- unknown

12 Nov 2025 22:13

Replied by unknown on topic 7i92 cnc motion controller from aliexpress?

7i92 cnc motion controller from aliexpress?

Category: Driver Boards

- Reyes

- Reyes

12 Nov 2025 22:05

Replied by Reyes on topic 7i92 cnc motion controller from aliexpress?

7i92 cnc motion controller from aliexpress?

Category: Driver Boards

- Reyes

- Reyes

12 Nov 2025 22:03

Replied by Reyes on topic 7i92 cnc motion controller from aliexpress?

7i92 cnc motion controller from aliexpress?

Category: Driver Boards

- miro199315

- miro199315

12 Nov 2025 22:01

Configuration Schnider electric ILA2 Servo was created by miro199315

Configuration Schnider electric ILA2 Servo

Category: EtherCAT

- tommylight

12 Nov 2025 21:56

Replied by tommylight on topic Avon 3000 Mill retrofit

Avon 3000 Mill retrofit

Category: Milling Machines

- tommylight

12 Nov 2025 21:53

Replied by tommylight on topic issues with cnc 2.9

issues with cnc 2.9

Category: General LinuxCNC Questions

- davmer42

12 Nov 2025 21:48

Replied by davmer42 on topic issues with cnc 2.9

issues with cnc 2.9

Category: General LinuxCNC Questions

- zoeper

- zoeper

12 Nov 2025 21:42

Replied by zoeper on topic Avon 3000 Mill retrofit

Avon 3000 Mill retrofit

Category: Milling Machines

Time to create page: 0.564 seconds