Search Results (Searched for: )

- cmorley

- cmorley

11 Nov 2025 02:54

Replied by cmorley on topic qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

Category: Qtvcp

- EDesro

- EDesro

11 Nov 2025 02:02

Replied by EDesro on topic qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

Category: Qtvcp

- EDesro

- EDesro

10 Nov 2025 23:55

Replied by EDesro on topic qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

Category: Qtvcp

- EDesro

- EDesro

10 Nov 2025 23:51

Replied by EDesro on topic qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

Category: Qtvcp

- unknown

- unknown

10 Nov 2025 23:13

Replied by unknown on topic [SOLVED] Backlash issues on Y-AXIS

[SOLVED] Backlash issues on Y-AXIS

Category: Advanced Configuration

- NidyCNC

- NidyCNC

10 Nov 2025 23:07

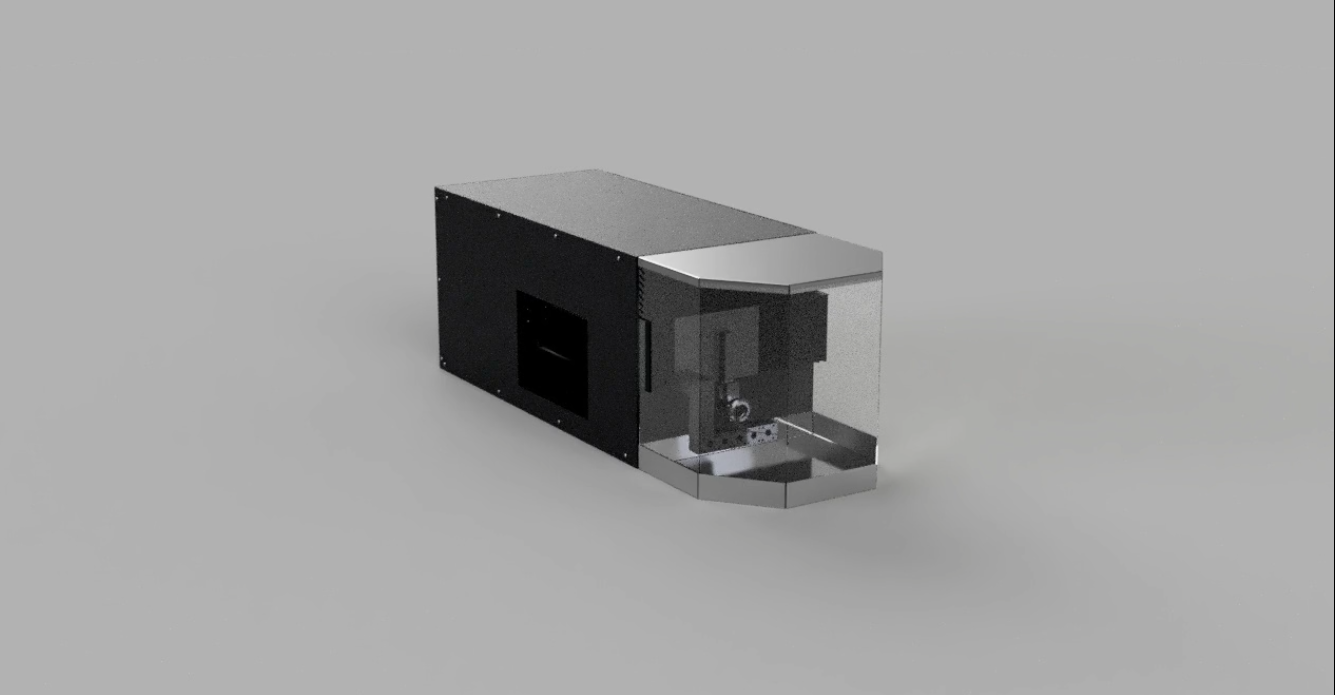

Desktop swiss cnc epoxy granite desktop lathe - Nidycnc was created by NidyCNC

Desktop swiss cnc epoxy granite desktop lathe - Nidycnc

Category: Turning

- Hakan

- Hakan

10 Nov 2025 23:05

Replied by Hakan on topic ASDA-A2-1521-E parameter list for ethercat com

ASDA-A2-1521-E parameter list for ethercat com

Category: EtherCAT

- Hakan

- Hakan

10 Nov 2025 22:54 - 10 Nov 2025 22:59

Replied by Hakan on topic Trouble with Cia402 drive configuration

Trouble with Cia402 drive configuration

Category: EtherCAT

- Beovoxo

- Beovoxo

10 Nov 2025 22:14

ASDA-A2-1521-E parameter list for ethercat com was created by Beovoxo

ASDA-A2-1521-E parameter list for ethercat com

Category: EtherCAT

- langdons

10 Nov 2025 22:09

Replied by langdons on topic qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

Category: Qtvcp

- langdons

10 Nov 2025 22:06

Replied by langdons on topic [SOLVED] Backlash issues on Y-AXIS

[SOLVED] Backlash issues on Y-AXIS

Category: Advanced Configuration

- langdons

10 Nov 2025 22:03

Replied by langdons on topic qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

qtdragon crash during 3d viewer translation (QTvcp ERROR! Message # 1)

Category: Qtvcp

- davmer42

10 Nov 2025 21:39

Replied by davmer42 on topic issues with cnc 2.9

issues with cnc 2.9

Category: General LinuxCNC Questions

- peterpan

- peterpan

10 Nov 2025 21:35

Replied by peterpan on topic Trouble with Cia402 drive configuration

Trouble with Cia402 drive configuration

Category: EtherCAT

- Robert312

- Robert312

10 Nov 2025 21:30

carousel component integration was created by Robert312

carousel component integration

Category: General LinuxCNC Questions

Time to create page: 0.213 seconds