Search Results (Searched for: )

- karnalta

- karnalta

28 Dec 2024 18:01 - 28 Dec 2024 18:12

Replied by karnalta on topic Easy way to compensate skew in X/Y axis ?

Easy way to compensate skew in X/Y axis ?

Category: General LinuxCNC Questions

- Aciera

28 Dec 2024 17:21

Replied by Aciera on topic Easy way to compensate skew in X/Y axis ?

Easy way to compensate skew in X/Y axis ?

Category: General LinuxCNC Questions

- karnalta

- karnalta

28 Dec 2024 16:26

Easy way to compensate skew in X/Y axis ? was created by karnalta

Easy way to compensate skew in X/Y axis ?

Category: General LinuxCNC Questions

- Blume

- Blume

28 Dec 2024 15:40

- MaHa

- MaHa

28 Dec 2024 15:17

Replied by MaHa on topic LinuxCNC 2.9.x hand wheel xhc-whb04b OFF/ON problem

LinuxCNC 2.9.x hand wheel xhc-whb04b OFF/ON problem

Category: Installing LinuxCNC

- tu_koper

- tu_koper

28 Dec 2024 15:02

Replied by tu_koper on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- Lcvette

28 Dec 2024 14:12

- tu_koper

- tu_koper

28 Dec 2024 13:58

Replied by tu_koper on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- TooTall18T

28 Dec 2024 13:46

LinuxCNC 2.9.x hand wheel xhc-whb04b OFF/ON problem was created by TooTall18T

LinuxCNC 2.9.x hand wheel xhc-whb04b OFF/ON problem

Category: Installing LinuxCNC

- Lcvette

28 Dec 2024 13:21

- Trihwangyudi1990

- Trihwangyudi1990

28 Dec 2024 11:24 - 29 Dec 2024 09:43

Replied by Trihwangyudi1990 on topic ESP32/S2/S3 LinuxCNC Controller (6 axis hardware step gen), USB plug-and-play

ESP32/S2/S3 LinuxCNC Controller (6 axis hardware step gen), USB plug-and-play

Category: Computers and Hardware

- Grotius

28 Dec 2024 11:10 - 28 Dec 2024 11:35

- Blume

- Blume

28 Dec 2024 10:55

- zelo

- zelo

28 Dec 2024 09:44 - 28 Dec 2024 13:26

Replied by zelo on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- thomaseg

- thomaseg

28 Dec 2024 09:19

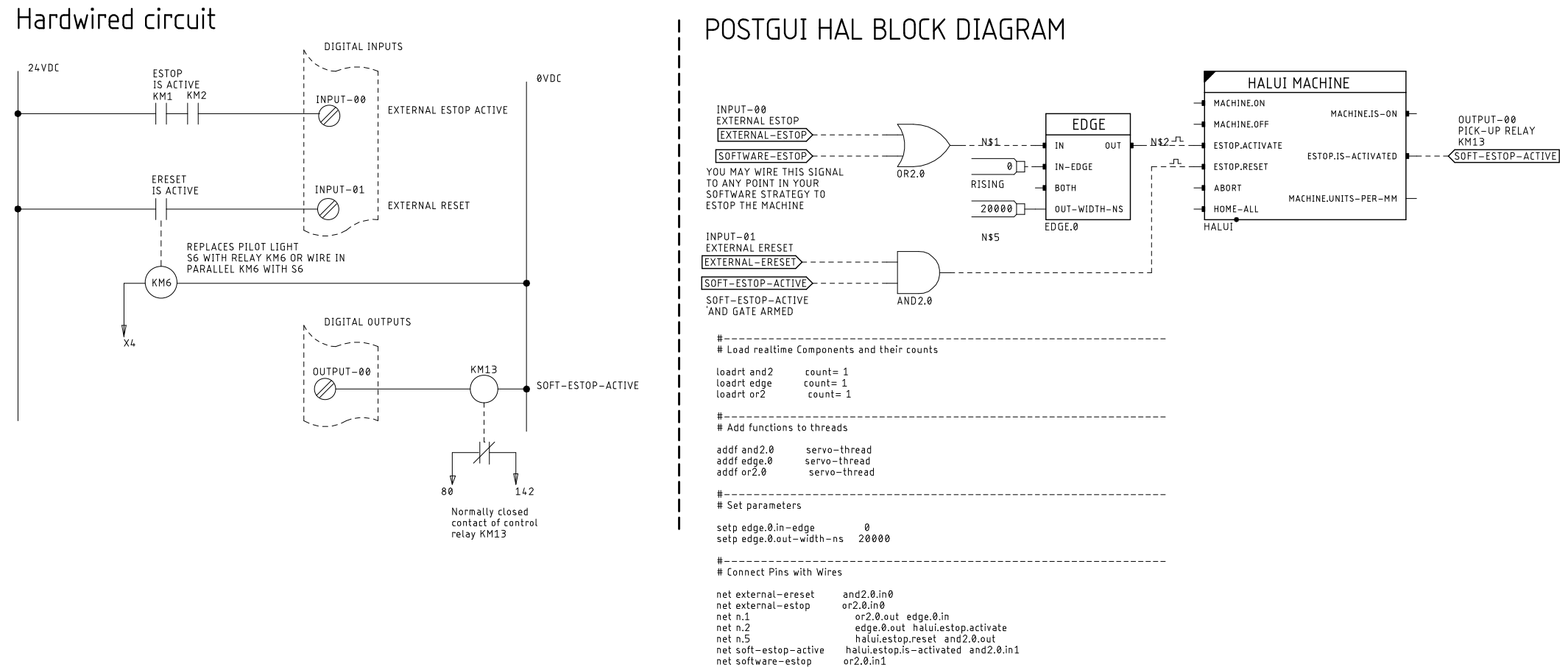

Replied by thomaseg on topic Physical safety relay and software estop latch working together?

Physical safety relay and software estop latch working together?

Category: HAL

Time to create page: 0.432 seconds