Search Results (Searched for: )

- gardenweazel

14 Dec 2024 14:20 - 14 Dec 2024 14:23

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Inconsistent values from Versaprobe

Category: Qtvcp

- tommylight

14 Dec 2024 14:05

Replied by tommylight on topic Improving Base Thread Jitter

Improving Base Thread Jitter

Category: Installing LinuxCNC

- Lcvette

14 Dec 2024 14:02

Replied by Lcvette on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

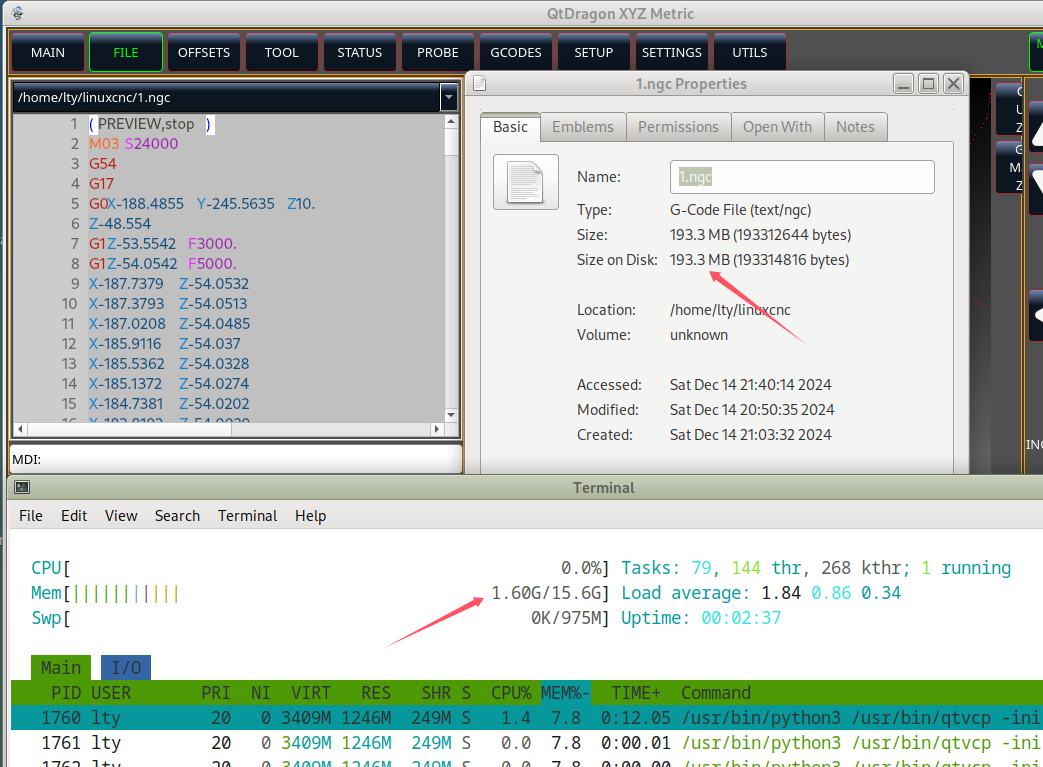

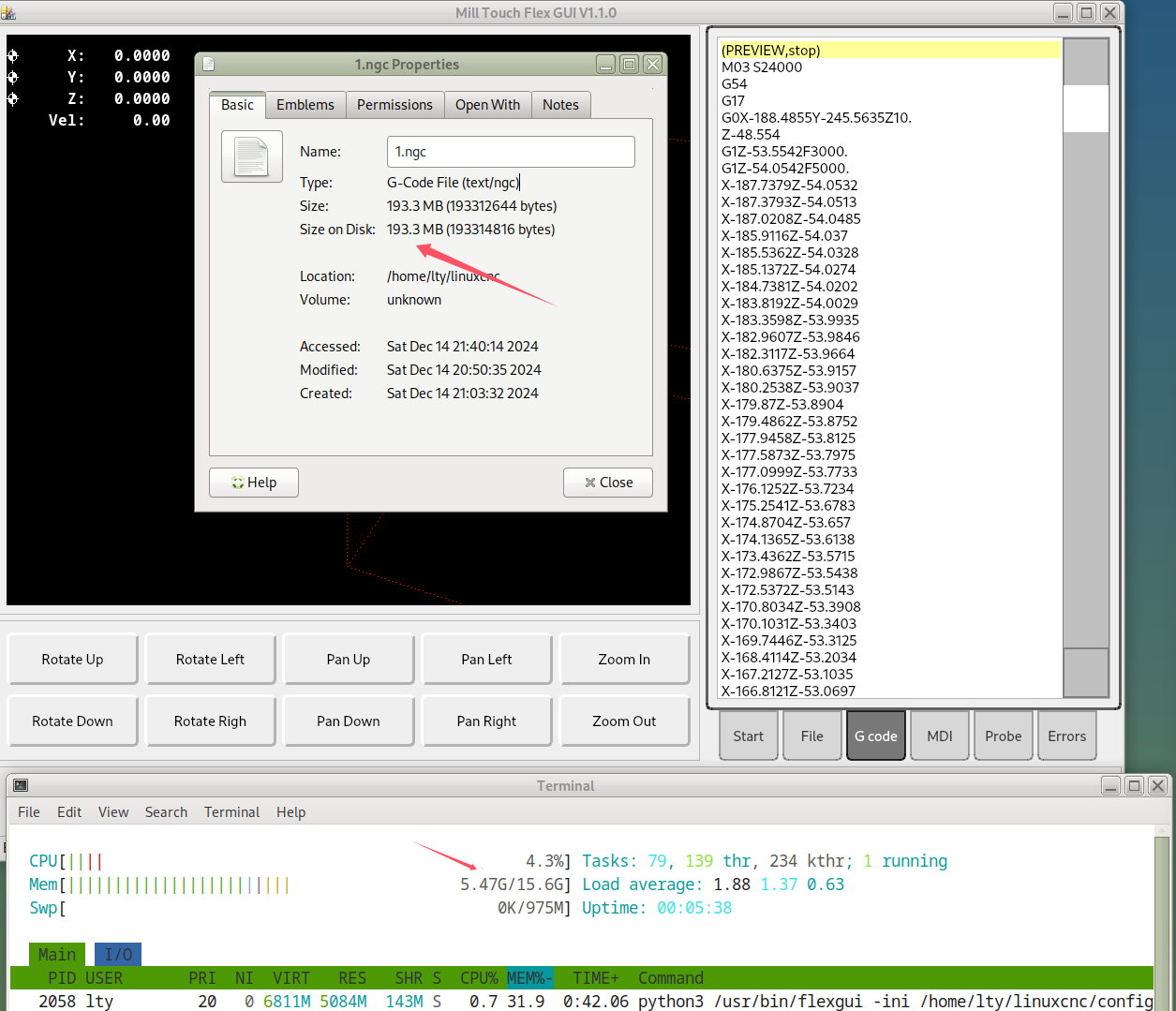

- kjlty

- kjlty

14 Dec 2024 14:01

- kjlty

- kjlty

14 Dec 2024 13:56

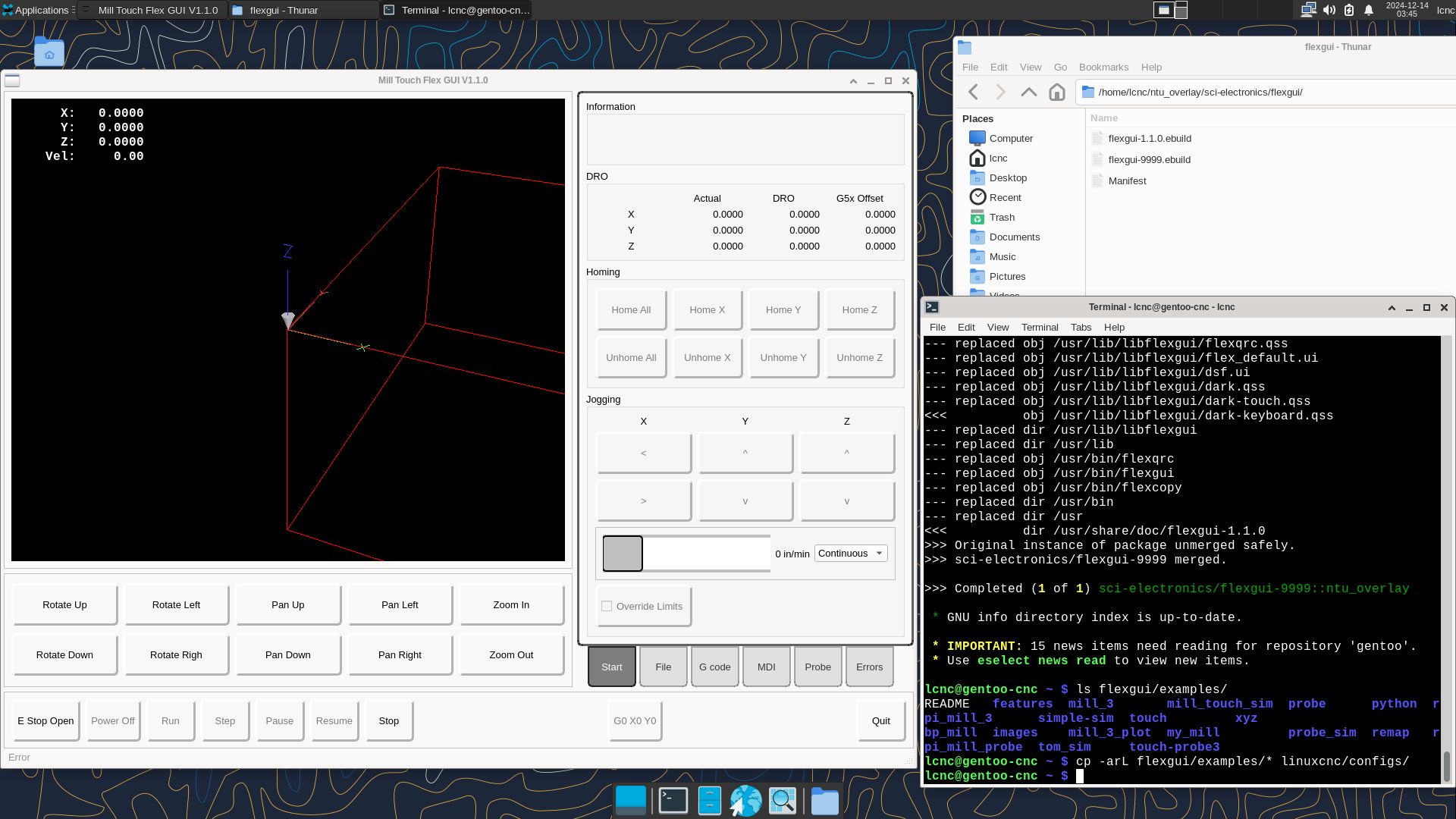

- Lcvette

14 Dec 2024 13:31

- Mitch66

- Mitch66

14 Dec 2024 13:20

Replied by Mitch66 on topic Improving Base Thread Jitter

Improving Base Thread Jitter

Category: Installing LinuxCNC

- seebaer1976

- seebaer1976

14 Dec 2024 13:13 - 14 Dec 2024 13:49

Replied by seebaer1976 on topic Inconsistent values from Versaprobe

Inconsistent values from Versaprobe

Category: Qtvcp

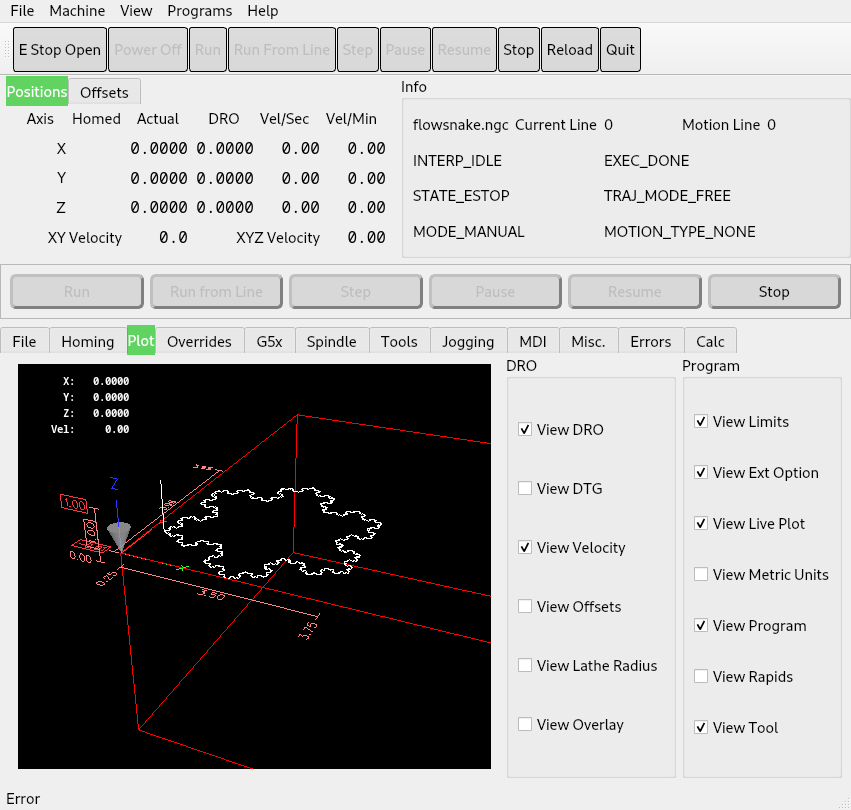

- JT

14 Dec 2024 11:29 - 14 Dec 2024 12:19

- JT

14 Dec 2024 11:21

- Cant do this anymore bye all

14 Dec 2024 11:08

Replied by Cant do this anymore bye all on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- HansU

14 Dec 2024 10:35

Building debian package without GTK2 was created by HansU

Building debian package without GTK2

Category: Installing LinuxCNC

- rodw

14 Dec 2024 10:18

Replied by rodw on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- gitin

- gitin

14 Dec 2024 09:24

Replied by gitin on topic Equivalent of some Fanuc codes

Equivalent of some Fanuc codes

Category: General LinuxCNC Questions

- Cant do this anymore bye all

14 Dec 2024 09:09

Replied by Cant do this anymore bye all on topic Mesa firmware versions and updating

Mesa firmware versions and updating

Category: Driver Boards

Time to create page: 0.972 seconds