Search Results (Searched for: )

- tommylight

12 Dec 2024 20:31

Replied by tommylight on topic Mesa firmware versions and updating

Mesa firmware versions and updating

Category: Driver Boards

- PCW

12 Dec 2024 20:27

Replied by PCW on topic Solution fo "hm2 error finishing read" with no good PC

Solution fo "hm2 error finishing read" with no good PC

Category: Computers and Hardware

- aDm1N

12 Dec 2024 20:06

Replied by aDm1N on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- greg23_78

- greg23_78

12 Dec 2024 19:57

Replied by greg23_78 on topic Solution fo "hm2 error finishing read" with no good PC

Solution fo "hm2 error finishing read" with no good PC

Category: Computers and Hardware

- Lisov_R

- Lisov_R

12 Dec 2024 19:55

Replied by Lisov_R on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- Ricoch3T

- Ricoch3T

12 Dec 2024 19:55

- greg23_78

- greg23_78

12 Dec 2024 19:54

Replied by greg23_78 on topic Solution fo "hm2 error finishing read" with no good PC

Solution fo "hm2 error finishing read" with no good PC

Category: Computers and Hardware

- PCW

12 Dec 2024 19:45

Replied by PCW on topic Solution fo "hm2 error finishing read" with no good PC

Solution fo "hm2 error finishing read" with no good PC

Category: Computers and Hardware

- greg23_78

- greg23_78

12 Dec 2024 19:37

Replied by greg23_78 on topic Solution fo "hm2 error finishing read" with no good PC

Solution fo "hm2 error finishing read" with no good PC

Category: Computers and Hardware

- PCW

12 Dec 2024 19:25

Replied by PCW on topic Solution fo "hm2 error finishing read" with no good PC

Solution fo "hm2 error finishing read" with no good PC

Category: Computers and Hardware

- greg23_78

- greg23_78

12 Dec 2024 19:05

Replied by greg23_78 on topic Solution fo "hm2 error finishing read" with no good PC

Solution fo "hm2 error finishing read" with no good PC

Category: Computers and Hardware

- aDm1N

12 Dec 2024 19:00 - 12 Dec 2024 19:01

Replied by aDm1N on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- PCW

12 Dec 2024 18:45

Replied by PCW on topic Solution fo "hm2 error finishing read" with no good PC

Solution fo "hm2 error finishing read" with no good PC

Category: Computers and Hardware

- greg23_78

- greg23_78

12 Dec 2024 18:22 - 12 Dec 2024 18:36

Replied by greg23_78 on topic Solution fo "hm2 error finishing read" with no good PC

Solution fo "hm2 error finishing read" with no good PC

Category: Computers and Hardware

- rodw

12 Dec 2024 17:48

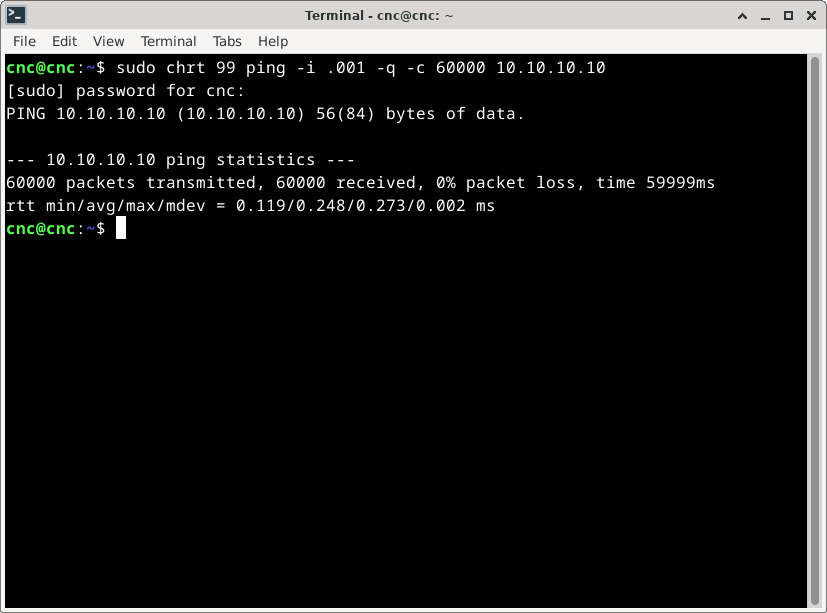

Replied by rodw on topic Improving Base Thread Jitter

Improving Base Thread Jitter

Category: Installing LinuxCNC

Time to create page: 0.534 seconds