Search Results (Searched for: )

- partec

- partec

09 Dec 2024 11:12

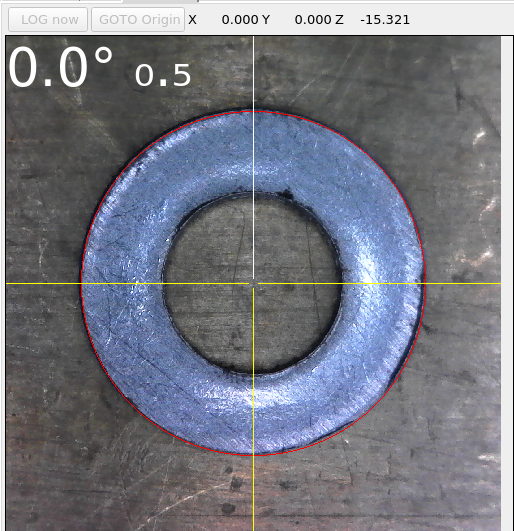

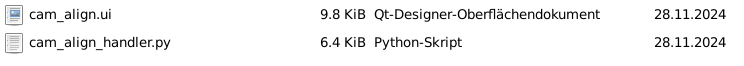

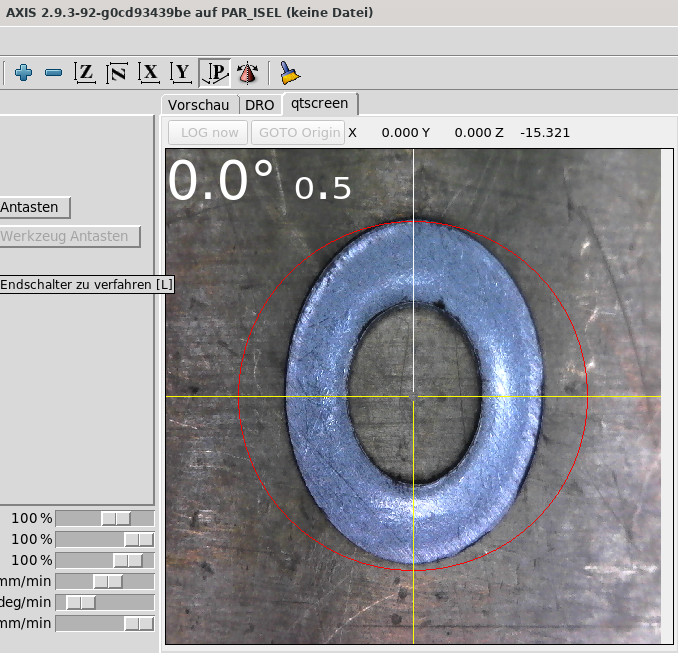

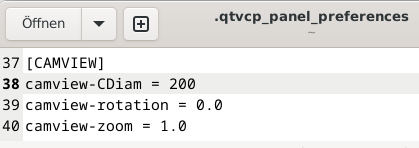

Replied by partec on topic camera resolution doesn' fit

camera resolution doesn' fit

Category: Qtvcp

- my1987toyota

09 Dec 2024 10:49

FreeCAD 1.0 Who's using it? was created by my1987toyota

FreeCAD 1.0 Who's using it?

Category: CAD CAM

- vibram

- vibram

09 Dec 2024 09:36 - 09 Dec 2024 09:36

Replied by vibram on topic Ethercat-conf.xml with beckhoff el1008

Ethercat-conf.xml with beckhoff el1008

Category: EtherCAT

- abdulasis12

- abdulasis12

09 Dec 2024 08:55

Replied by abdulasis12 on topic Feedback control XY not full speed run G1 when curve or Arc

Feedback control XY not full speed run G1 when curve or Arc

Category: General LinuxCNC Questions

- meister

- meister

09 Dec 2024 08:41

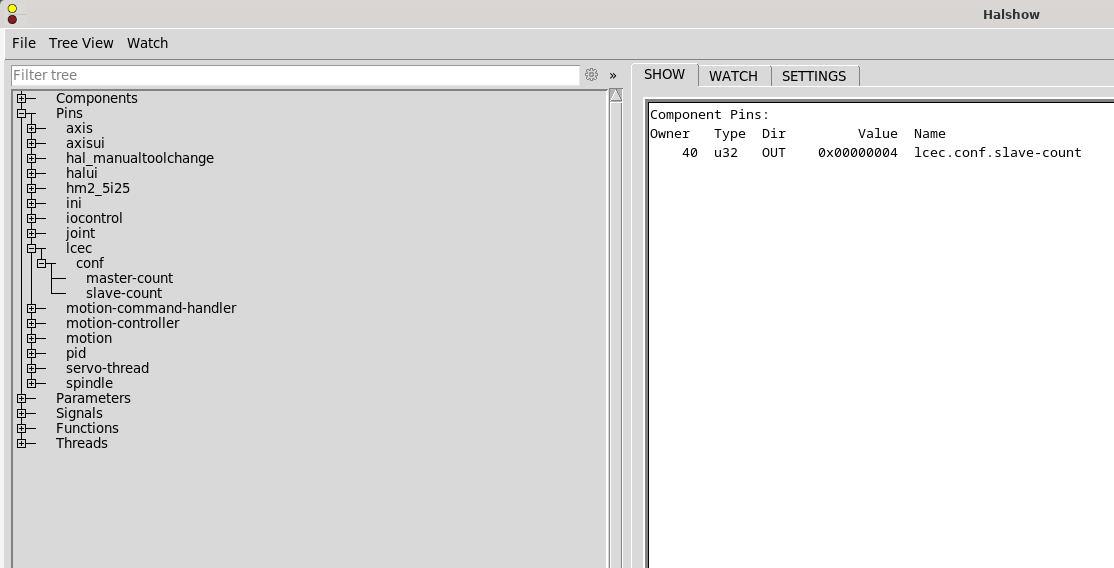

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- MirkoCNC

- MirkoCNC

09 Dec 2024 08:23

Replied by MirkoCNC on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- partec

- partec

09 Dec 2024 08:18 - 09 Dec 2024 10:46

Replied by partec on topic camera resolution doesn' fit

camera resolution doesn' fit

Category: Qtvcp

- MirkoCNC

- MirkoCNC

09 Dec 2024 08:16

Replied by MirkoCNC on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- cmorley

- cmorley

09 Dec 2024 04:26

- snowgoer540

09 Dec 2024 04:11

- fully_defined

09 Dec 2024 01:18

- jmelson

- jmelson

09 Dec 2024 00:53

Replied by jmelson on topic Kuka robot project - hardware choice

Kuka robot project - hardware choice

Category: Driver Boards

- JT

09 Dec 2024 00:47

- jmelson

- jmelson

09 Dec 2024 00:46

Replied by jmelson on topic Kuka robot project - hardware choice

Kuka robot project - hardware choice

Category: Driver Boards

- jmelson

- jmelson

09 Dec 2024 00:42

Replied by jmelson on topic Kuka robot project - hardware choice

Kuka robot project - hardware choice

Category: Driver Boards

Time to create page: 0.444 seconds