Search Results (Searched for: )

- PatJac

- PatJac

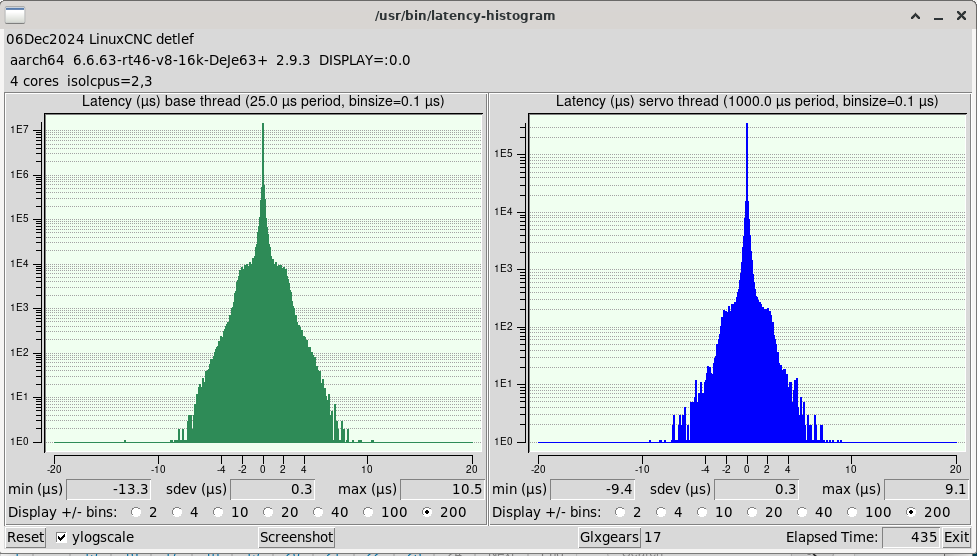

Real-Time Kernel with Orange Pi 4 LTS

Category: General LinuxCNC Questions

Did all those,yes ,first change i made ,fdtfile=rockchip/rk3399-orangepi-4.dtb, simply would not make it to login prompt ,i test again ,it hang led blink ,there is usb power but frozen kernel.And what result do you get?

lts is fine ,no change needed .

I never tried another armbian opi4lts image on this 4 ,your's only.

Results are not good , is it the gpu acceleration or rt or both ,i get random results ,lags,oops & hangs sometimes at boot & shutdown with isolcpu ,

system is snappy without cpu isolation ,did tested a lot , probably too many isolcpu combinations ,had fun installing all the lightest i could,one is jwm ,minimal desktop.

Logs i saw show knowed es8316 sound error at boot ,and memory allocation or cache management at shutdown (when oops&hangs) .

isolcpu=4,5 seems the best (or a little more stable) ,with wifi/ethernet(7i92 )/3 x glxgears ,

histogram state base/servo 48/37uSec stable, open firefox ,it spike to 120/130 .

Never detailed , it's an opi4 4gb 16gb emmc v1.4 ,

tested here from emmc install .Well powered(branded 4Amp ps) with heatsink&fan .

@roya , if you work on this image or optimize another one 6.12 , i'll be glad to test some more , and i guess there should be some fixes in 6.12 , or regressions...

Thanks for sharing your work .

- yaska

- yaska

Flex gui touchoff_le

Category: Flex GUI

- vibram

- vibram

6i25 and 7i77 , what am I doing wrong?

Category: PnCConf Wizard

I have a 6i25 flashed with firmware 5i25_7i77x2

5i25 W1 ,W2, W3, W4 are up

7i77 W5, W1, W4,W12 left handed,

CR1, CR6 and CR7 are yellow, no other LED turned on

loadrt hm2_pci output:

hm2_pci: loading Mesa AnyIO HostMot2 driver version 0.7

hm2_pci: discovered 5i25 at 0000:02:00.0

hm2/hm2_5i25.0: Low Level init 0.15

hm2/hm2_5i25.0: Smart Serial Firmware Version 43

Board hm2_5i25.0.7i77.0.1 Hardware Mode 0 = standard

Board hm2_5i25.0.7i77.0.1 Software Mode 0 = analogout_enables

hm2/hm2_5i25.0: 34 I/O Pins used:

hm2/hm2_5i25.0: IO Pin 000 (P3-01): IOPort

hm2/hm2_5i25.0: IO Pin 001 (P3-14): IOPort

hm2/hm2_5i25.0: IO Pin 002 (P3-02): IOPort

hm2/hm2_5i25.0: IO Pin 003 (P3-15): Smart Serial Interface #0, pin tx1 (Output)

hm2/hm2_5i25.0: IO Pin 004 (P3-03): Smart Serial Interface #0, pin rx1 (Input)

hm2/hm2_5i25.0: IO Pin 005 (P3-16): IOPort

hm2/hm2_5i25.0: IO Pin 006 (P3-04): IOPort

hm2/hm2_5i25.0: IO Pin 007 (P3-17): Muxed Encoder Select #0, pin Mux Select 0 (Output)

hm2/hm2_5i25.0: IO Pin 008 (P3-05): Muxed Encoder #0, pin Muxed A (Input)

hm2/hm2_5i25.0: IO Pin 009 (P3-06): Muxed Encoder #0, pin Muxed B (Input)

hm2/hm2_5i25.0: IO Pin 010 (P3-07): Muxed Encoder #0, pin Muxed Index (Input)

hm2/hm2_5i25.0: IO Pin 011 (P3-08): Muxed Encoder #1, pin Muxed A (Input)

hm2/hm2_5i25.0: IO Pin 012 (P3-09): Muxed Encoder #1, pin Muxed B (Input)

hm2/hm2_5i25.0: IO Pin 013 (P3-10): Muxed Encoder #1, pin Muxed Index (Input)

hm2/hm2_5i25.0: IO Pin 014 (P3-11): Muxed Encoder #2, pin Muxed A (Input)

hm2/hm2_5i25.0: IO Pin 015 (P3-12): Muxed Encoder #2, pin Muxed B (Input)

hm2/hm2_5i25.0: IO Pin 016 (P3-13): Muxed Encoder #2, pin Muxed Index (Input)

hm2/hm2_5i25.0: IO Pin 017 (P2-01): IOPort

hm2/hm2_5i25.0: IO Pin 018 (P2-14): IOPort

hm2/hm2_5i25.0: IO Pin 019 (P2-02): IOPort

hm2/hm2_5i25.0: IO Pin 020 (P2-15): IOPort

hm2/hm2_5i25.0: IO Pin 021 (P2-03): IOPort

hm2/hm2_5i25.0: IO Pin 022 (P2-16): IOPort

hm2/hm2_5i25.0: IO Pin 023 (P2-04): IOPort

hm2/hm2_5i25.0: IO Pin 024 (P2-17): Muxed Encoder Select #6, pin Mux Select 0 (Output)

hm2/hm2_5i25.0: IO Pin 025 (P2-05): Muxed Encoder #3, pin Muxed A (Input)

hm2/hm2_5i25.0: IO Pin 026 (P2-06): Muxed Encoder #3, pin Muxed B (Input)

hm2/hm2_5i25.0: IO Pin 027 (P2-07): Muxed Encoder #3, pin Muxed Index (Input)

hm2/hm2_5i25.0: IO Pin 028 (P2-08): Muxed Encoder #4, pin Muxed A (Input)

hm2/hm2_5i25.0: IO Pin 029 (P2-09): Muxed Encoder #4, pin Muxed B (Input)

hm2/hm2_5i25.0: IO Pin 030 (P2-10): Muxed Encoder #4, pin Muxed Index (Input)

hm2/hm2_5i25.0: IO Pin 031 (P2-11): Muxed Encoder #5, pin Muxed A (Input)

hm2/hm2_5i25.0: IO Pin 032 (P2-12): Muxed Encoder #5, pin Muxed B (Input)

hm2/hm2_5i25.0: IO Pin 033 (P2-13): Muxed Encoder #5, pin Muxed Index (Input)

hm2/hm2_5i25.0: registered

show pin output:omponent Pins:

Owner Type Dir Value Name

11 s32 OUT 0 hm2_5i25.0.0.debug

11 bit IN FALSE hm2_5i25.0.7i77.0.1.analogena

11 float IN 0 hm2_5i25.0.7i77.0.1.analogout0

11 float IN 0 hm2_5i25.0.7i77.0.1.analogout1

11 float IN 0 hm2_5i25.0.7i77.0.1.analogout2

11 float IN 0 hm2_5i25.0.7i77.0.1.analogout3

11 float IN 0 hm2_5i25.0.7i77.0.1.analogout4

11 float IN 0 hm2_5i25.0.7i77.0.1.analogout5

11 bit IN FALSE hm2_5i25.0.7i77.0.1.spinena

11 s32 OUT 0 hm2_5i25.0.encoder.00.count

11 s32 OUT 0 hm2_5i25.0.encoder.00.count-latched

11 bit I/O FALSE hm2_5i25.0.encoder.00.index-enable

11 bit OUT TRUE hm2_5i25.0.encoder.00.input-a

11 bit OUT FALSE hm2_5i25.0.encoder.00.input-b

11 bit OUT TRUE hm2_5i25.0.encoder.00.input-index

11 float OUT 0 hm2_5i25.0.encoder.00.position

11 float OUT 0 hm2_5i25.0.encoder.00.position-latched

11 bit OUT FALSE hm2_5i25.0.encoder.00.quad-error

11 bit IN FALSE hm2_5i25.0.encoder.00.quad-error-enable

11 s32 OUT 1 hm2_5i25.0.encoder.00.rawcounts

11 s32 OUT 1 hm2_5i25.0.encoder.00.rawlatch

11 bit IN FALSE hm2_5i25.0.encoder.00.reset

11 float OUT 0 hm2_5i25.0.encoder.00.velocity

11 float OUT 0 hm2_5i25.0.encoder.00.velocity-rpm

11 s32 OUT 0 hm2_5i25.0.encoder.01.count

11 s32 OUT 0 hm2_5i25.0.encoder.01.count-latched

11 bit I/O FALSE hm2_5i25.0.encoder.01.index-enable

11 bit OUT FALSE hm2_5i25.0.encoder.01.input-a

11 bit OUT TRUE hm2_5i25.0.encoder.01.input-b

11 bit OUT FALSE hm2_5i25.0.encoder.01.input-index

11 float OUT 0 hm2_5i25.0.encoder.01.position

11 float OUT 0 hm2_5i25.0.encoder.01.position-latched

11 bit OUT FALSE hm2_5i25.0.encoder.01.quad-error

11 bit IN FALSE hm2_5i25.0.encoder.01.quad-error-enable

11 s32 OUT 65535 hm2_5i25.0.encoder.01.rawcounts

11 s32 OUT 65535 hm2_5i25.0.encoder.01.rawlatch

11 bit IN FALSE hm2_5i25.0.encoder.01.reset

11 float OUT 0 hm2_5i25.0.encoder.01.velocity

11 float OUT 0 hm2_5i25.0.encoder.01.velocity-rpm

11 s32 OUT 0 hm2_5i25.0.encoder.02.count

11 s32 OUT 0 hm2_5i25.0.encoder.02.count-latched

11 bit I/O FALSE hm2_5i25.0.encoder.02.index-enable

11 bit OUT FALSE hm2_5i25.0.encoder.02.input-a

11 bit OUT TRUE hm2_5i25.0.encoder.02.input-b

11 bit OUT FALSE hm2_5i25.0.encoder.02.input-index

11 float OUT 0 hm2_5i25.0.encoder.02.position

11 float OUT 0 hm2_5i25.0.encoder.02.position-latched

11 bit OUT FALSE hm2_5i25.0.encoder.02.quad-error

11 bit IN FALSE hm2_5i25.0.encoder.02.quad-error-enable

11 s32 OUT 65535 hm2_5i25.0.encoder.02.rawcounts

11 s32 OUT 65535 hm2_5i25.0.encoder.02.rawlatch

11 bit IN FALSE hm2_5i25.0.encoder.02.reset

11 float OUT 0 hm2_5i25.0.encoder.02.velocity

11 float OUT 0 hm2_5i25.0.encoder.02.velocity-rpm

11 s32 OUT 0 hm2_5i25.0.encoder.03.count

11 s32 OUT 0 hm2_5i25.0.encoder.03.count-latched

11 bit I/O FALSE hm2_5i25.0.encoder.03.index-enable

11 bit OUT FALSE hm2_5i25.0.encoder.03.input-a

11 bit OUT FALSE hm2_5i25.0.encoder.03.input-b

11 bit OUT TRUE hm2_5i25.0.encoder.03.input-index

11 float OUT 0 hm2_5i25.0.encoder.03.position

11 float OUT 0 hm2_5i25.0.encoder.03.position-latched

11 bit OUT FALSE hm2_5i25.0.encoder.03.quad-error

11 bit IN FALSE hm2_5i25.0.encoder.03.quad-error-enable

11 s32 OUT 0 hm2_5i25.0.encoder.03.rawcounts

11 s32 OUT 0 hm2_5i25.0.encoder.03.rawlatch

11 bit IN FALSE hm2_5i25.0.encoder.03.reset

11 float OUT 0 hm2_5i25.0.encoder.03.velocity

11 float OUT 0 hm2_5i25.0.encoder.03.velocity-rpm

11 s32 OUT 0 hm2_5i25.0.encoder.04.count

11 s32 OUT 0 hm2_5i25.0.encoder.04.count-latched

11 bit I/O FALSE hm2_5i25.0.encoder.04.index-enable

11 bit OUT TRUE hm2_5i25.0.encoder.04.input-a

11 bit OUT FALSE hm2_5i25.0.encoder.04.input-b

11 bit OUT TRUE hm2_5i25.0.encoder.04.input-index

11 float OUT 0 hm2_5i25.0.encoder.04.position

11 float OUT 0 hm2_5i25.0.encoder.04.position-latched

11 bit OUT FALSE hm2_5i25.0.encoder.04.quad-error

11 bit IN FALSE hm2_5i25.0.encoder.04.quad-error-enable

11 s32 OUT 1 hm2_5i25.0.encoder.04.rawcounts

11 s32 OUT 1 hm2_5i25.0.encoder.04.rawlatch

11 bit IN FALSE hm2_5i25.0.encoder.04.reset

11 float OUT 0 hm2_5i25.0.encoder.04.velocity

11 float OUT 0 hm2_5i25.0.encoder.04.velocity-rpm

11 s32 OUT 0 hm2_5i25.0.encoder.05.count

11 s32 OUT 0 hm2_5i25.0.encoder.05.count-latched

11 bit I/O FALSE hm2_5i25.0.encoder.05.index-enable

11 bit OUT TRUE hm2_5i25.0.encoder.05.input-a

11 bit OUT FALSE hm2_5i25.0.encoder.05.input-b

11 bit OUT TRUE hm2_5i25.0.encoder.05.input-index

11 float OUT 0 hm2_5i25.0.encoder.05.position

11 float OUT 0 hm2_5i25.0.encoder.05.position-latched

11 bit OUT FALSE hm2_5i25.0.encoder.05.quad-error

11 bit IN FALSE hm2_5i25.0.encoder.05.quad-error-enable

11 s32 OUT 1 hm2_5i25.0.encoder.05.rawcounts

11 s32 OUT 1 hm2_5i25.0.encoder.05.rawlatch

11 bit IN FALSE hm2_5i25.0.encoder.05.reset

11 float OUT 0 hm2_5i25.0.encoder.05.velocity

11 float OUT 0 hm2_5i25.0.encoder.05.velocity-rpm

11 s32 OUT 0 hm2_5i25.0.encoder.06.count

11 s32 OUT 0 hm2_5i25.0.encoder.06.count-latched

11 bit I/O FALSE hm2_5i25.0.encoder.06.index-enable

11 bit OUT TRUE hm2_5i25.0.encoder.06.input-a

11 bit OUT TRUE hm2_5i25.0.encoder.06.input-b

11 bit OUT FALSE hm2_5i25.0.encoder.06.input-index

11 float OUT 0 hm2_5i25.0.encoder.06.position

11 float OUT 0 hm2_5i25.0.encoder.06.position-latched

11 bit OUT FALSE hm2_5i25.0.encoder.06.quad-error

11 bit IN FALSE hm2_5i25.0.encoder.06.quad-error-enable

11 s32 OUT 0 hm2_5i25.0.encoder.06.rawcounts

11 s32 OUT 0 hm2_5i25.0.encoder.06.rawlatch

11 bit IN FALSE hm2_5i25.0.encoder.06.reset

11 float OUT 0 hm2_5i25.0.encoder.06.velocity

11 float OUT 0 hm2_5i25.0.encoder.06.velocity-rpm

11 s32 OUT 0 hm2_5i25.0.encoder.07.count

11 s32 OUT 0 hm2_5i25.0.encoder.07.count-latched

11 bit I/O FALSE hm2_5i25.0.encoder.07.index-enable

11 bit OUT TRUE hm2_5i25.0.encoder.07.input-a

11 bit OUT TRUE hm2_5i25.0.encoder.07.input-b

11 bit OUT FALSE hm2_5i25.0.encoder.07.input-index

11 float OUT 0 hm2_5i25.0.encoder.07.position

11 float OUT 0 hm2_5i25.0.encoder.07.position-latched

11 bit OUT FALSE hm2_5i25.0.encoder.07.quad-error

11 bit IN FALSE hm2_5i25.0.encoder.07.quad-error-enable

11 s32 OUT 0 hm2_5i25.0.encoder.07.rawcounts

11 s32 OUT 0 hm2_5i25.0.encoder.07.rawlatch

11 bit IN FALSE hm2_5i25.0.encoder.07.reset

11 float OUT 0 hm2_5i25.0.encoder.07.velocity

11 float OUT 0 hm2_5i25.0.encoder.07.velocity-rpm

11 s32 OUT 0 hm2_5i25.0.encoder.08.count

11 s32 OUT 0 hm2_5i25.0.encoder.08.count-latched

11 bit I/O FALSE hm2_5i25.0.encoder.08.index-enable

11 bit OUT TRUE hm2_5i25.0.encoder.08.input-a

11 bit OUT TRUE hm2_5i25.0.encoder.08.input-b

11 bit OUT FALSE hm2_5i25.0.encoder.08.input-index

11 float OUT 0 hm2_5i25.0.encoder.08.position

11 float OUT 0 hm2_5i25.0.encoder.08.position-latched

11 bit OUT FALSE hm2_5i25.0.encoder.08.quad-error

11 bit IN FALSE hm2_5i25.0.encoder.08.quad-error-enable

11 s32 OUT 0 hm2_5i25.0.encoder.08.rawcounts

11 s32 OUT 0 hm2_5i25.0.encoder.08.rawlatch

11 bit IN FALSE hm2_5i25.0.encoder.08.reset

11 float OUT 0 hm2_5i25.0.encoder.08.velocity

11 float OUT 0 hm2_5i25.0.encoder.08.velocity-rpm

11 s32 OUT 0 hm2_5i25.0.encoder.09.count

11 s32 OUT 0 hm2_5i25.0.encoder.09.count-latched

11 bit I/O FALSE hm2_5i25.0.encoder.09.index-enable

11 bit OUT TRUE hm2_5i25.0.encoder.09.input-a

11 bit OUT TRUE hm2_5i25.0.encoder.09.input-b

11 bit OUT FALSE hm2_5i25.0.encoder.09.input-index

11 float OUT 0 hm2_5i25.0.encoder.09.position

11 float OUT 0 hm2_5i25.0.encoder.09.position-latched

11 bit OUT FALSE hm2_5i25.0.encoder.09.quad-error

11 bit IN FALSE hm2_5i25.0.encoder.09.quad-error-enable

11 s32 OUT 0 hm2_5i25.0.encoder.09.rawcounts

11 s32 OUT 0 hm2_5i25.0.encoder.09.rawlatch

11 bit IN FALSE hm2_5i25.0.encoder.09.reset

11 float OUT 0 hm2_5i25.0.encoder.09.velocity

11 float OUT 0 hm2_5i25.0.encoder.09.velocity-rpm

11 s32 OUT 0 hm2_5i25.0.encoder.10.count

11 s32 OUT 0 hm2_5i25.0.encoder.10.count-latched

11 bit I/O FALSE hm2_5i25.0.encoder.10.index-enable

11 bit OUT TRUE hm2_5i25.0.encoder.10.input-a

11 bit OUT TRUE hm2_5i25.0.encoder.10.input-b

11 bit OUT FALSE hm2_5i25.0.encoder.10.input-index

11 float OUT 0 hm2_5i25.0.encoder.10.position

11 float OUT 0 hm2_5i25.0.encoder.10.position-latched

11 bit OUT FALSE hm2_5i25.0.encoder.10.quad-error

11 bit IN FALSE hm2_5i25.0.encoder.10.quad-error-enable

11 s32 OUT 0 hm2_5i25.0.encoder.10.rawcounts

11 s32 OUT 0 hm2_5i25.0.encoder.10.rawlatch

11 bit IN FALSE hm2_5i25.0.encoder.10.reset

11 float OUT 0 hm2_5i25.0.encoder.10.velocity

11 float OUT 0 hm2_5i25.0.encoder.10.velocity-rpm

11 s32 OUT 0 hm2_5i25.0.encoder.11.count

11 s32 OUT 0 hm2_5i25.0.encoder.11.count-latched

11 bit I/O FALSE hm2_5i25.0.encoder.11.index-enable

11 bit OUT TRUE hm2_5i25.0.encoder.11.input-a

11 bit OUT TRUE hm2_5i25.0.encoder.11.input-b

11 bit OUT FALSE hm2_5i25.0.encoder.11.input-index

11 float OUT 0 hm2_5i25.0.encoder.11.position

11 float OUT 0 hm2_5i25.0.encoder.11.position-latched

11 bit OUT FALSE hm2_5i25.0.encoder.11.quad-error

11 bit IN FALSE hm2_5i25.0.encoder.11.quad-error-enable

11 s32 OUT 0 hm2_5i25.0.encoder.11.rawcounts

11 s32 OUT 0 hm2_5i25.0.encoder.11.rawlatch

11 bit IN FALSE hm2_5i25.0.encoder.11.reset

11 float OUT 0 hm2_5i25.0.encoder.11.velocity

11 float OUT 0 hm2_5i25.0.encoder.11.velocity-rpm

11 bit IN FALSE hm2_5i25.0.encoder.hires-timestamp

11 u32 IN 0x007F2815 hm2_5i25.0.encoder.muxed-sample-frequency

11 bit OUT TRUE hm2_5i25.0.gpio.000.in

11 bit OUT FALSE hm2_5i25.0.gpio.000.in_not

11 bit IN FALSE hm2_5i25.0.gpio.000.out

11 bit OUT TRUE hm2_5i25.0.gpio.001.in

11 bit OUT FALSE hm2_5i25.0.gpio.001.in_not

11 bit IN FALSE hm2_5i25.0.gpio.001.out

11 bit OUT TRUE hm2_5i25.0.gpio.002.in

11 bit OUT FALSE hm2_5i25.0.gpio.002.in_not

11 bit IN FALSE hm2_5i25.0.gpio.002.out

11 bit OUT TRUE hm2_5i25.0.gpio.003.in

11 bit OUT FALSE hm2_5i25.0.gpio.003.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.004.in

11 bit OUT FALSE hm2_5i25.0.gpio.004.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.005.in

11 bit OUT FALSE hm2_5i25.0.gpio.005.in_not

11 bit IN FALSE hm2_5i25.0.gpio.005.out

11 bit OUT FALSE hm2_5i25.0.gpio.006.in

11 bit OUT TRUE hm2_5i25.0.gpio.006.in_not

11 bit IN FALSE hm2_5i25.0.gpio.006.out

11 bit OUT FALSE hm2_5i25.0.gpio.007.in

11 bit OUT TRUE hm2_5i25.0.gpio.007.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.008.in

11 bit OUT FALSE hm2_5i25.0.gpio.008.in_not

11 bit OUT FALSE hm2_5i25.0.gpio.009.in

11 bit OUT TRUE hm2_5i25.0.gpio.009.in_not

11 bit OUT FALSE hm2_5i25.0.gpio.010.in

11 bit OUT TRUE hm2_5i25.0.gpio.010.in_not

11 bit OUT FALSE hm2_5i25.0.gpio.011.in

11 bit OUT TRUE hm2_5i25.0.gpio.011.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.012.in

11 bit OUT FALSE hm2_5i25.0.gpio.012.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.013.in

11 bit OUT FALSE hm2_5i25.0.gpio.013.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.014.in

11 bit OUT FALSE hm2_5i25.0.gpio.014.in_not

11 bit OUT FALSE hm2_5i25.0.gpio.015.in

11 bit OUT TRUE hm2_5i25.0.gpio.015.in_not

11 bit OUT FALSE hm2_5i25.0.gpio.016.in

11 bit OUT TRUE hm2_5i25.0.gpio.016.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.017.in

11 bit OUT FALSE hm2_5i25.0.gpio.017.in_not

11 bit IN FALSE hm2_5i25.0.gpio.017.out

11 bit OUT TRUE hm2_5i25.0.gpio.018.in

11 bit OUT FALSE hm2_5i25.0.gpio.018.in_not

11 bit IN FALSE hm2_5i25.0.gpio.018.out

11 bit OUT TRUE hm2_5i25.0.gpio.019.in

11 bit OUT FALSE hm2_5i25.0.gpio.019.in_not

11 bit IN FALSE hm2_5i25.0.gpio.019.out

11 bit OUT TRUE hm2_5i25.0.gpio.020.in

11 bit OUT FALSE hm2_5i25.0.gpio.020.in_not

11 bit IN FALSE hm2_5i25.0.gpio.020.out

11 bit OUT TRUE hm2_5i25.0.gpio.021.in

11 bit OUT FALSE hm2_5i25.0.gpio.021.in_not

11 bit IN FALSE hm2_5i25.0.gpio.021.out

11 bit OUT TRUE hm2_5i25.0.gpio.022.in

11 bit OUT FALSE hm2_5i25.0.gpio.022.in_not

11 bit IN FALSE hm2_5i25.0.gpio.022.out

11 bit OUT TRUE hm2_5i25.0.gpio.023.in

11 bit OUT FALSE hm2_5i25.0.gpio.023.in_not

11 bit IN FALSE hm2_5i25.0.gpio.023.out

11 bit OUT TRUE hm2_5i25.0.gpio.024.in

11 bit OUT FALSE hm2_5i25.0.gpio.024.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.025.in

11 bit OUT FALSE hm2_5i25.0.gpio.025.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.026.in

11 bit OUT FALSE hm2_5i25.0.gpio.026.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.027.in

11 bit OUT FALSE hm2_5i25.0.gpio.027.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.028.in

11 bit OUT FALSE hm2_5i25.0.gpio.028.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.029.in

11 bit OUT FALSE hm2_5i25.0.gpio.029.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.030.in

11 bit OUT FALSE hm2_5i25.0.gpio.030.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.031.in

11 bit OUT FALSE hm2_5i25.0.gpio.031.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.032.in

11 bit OUT FALSE hm2_5i25.0.gpio.032.in_not

11 bit OUT TRUE hm2_5i25.0.gpio.033.in

11 bit OUT FALSE hm2_5i25.0.gpio.033.in_not

11 bit IN FALSE hm2_5i25.0.led.CR01

11 bit IN FALSE hm2_5i25.0.led.CR02

11 s32 OUT 0 hm2_5i25.0.read.time

11 s32 OUT 0 hm2_5i25.0.read_gpio.time

11 u32 OUT 0x00000000 hm2_5i25.0.sserial.port-0.fault-count

11 u32 OUT 0x00000000 hm2_5i25.0.sserial.port-0.port_state

11 u32 OUT 0x00000000 hm2_5i25.0.sserial.port-0.port_state2

11 u32 OUT 0x00000000 hm2_5i25.0.sserial.port-0.port_state3

11 bit IN TRUE hm2_5i25.0.sserial.port-0.run

11 bit I/O FALSE hm2_5i25.0.watchdog.has_bit

11 s32 OUT 0 hm2_5i25.0.write.time

11 s32 OUT 0 hm2_5i25.0.write_gpio.time

5 s32 OUT 0 th.time

Is it normal to only have 7i77 analog output and all gpio under 5i25 ?I'm a bit lost

Thank you

- Lcvette

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Deje63

- Deje63

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

I got it finally working very well with very low latency on my RPI 5

short description:

- take Raspberry OS 64bit Lite

- install Xfce4

- build the RT kernel the usual way

- install it

- install linuxcnc

It takes some time on the RPI.

As I am writing this in Firefox on this machine, latency-histogram (was started befor starting Firefox!) is running and 17 glxgears.

To be honest, so far I am very happy with.

Attached please also find a somewhat "script" to build from scratch.

- Toribio1898

- Toribio1898

LinuxCNC 32 BITS

Category: General LinuxCNC Questions

Could it be the nvidia card that my HP mini has? The 32-bit LinuxCnc, its start screen is stuck, I don't see any progress, to be able to install that version, on the other hand, Ubuntu starts up just fine and I think I could install it without problems, but I want to manage a machine with LinuxCnc 32 bits, I consider that Ubuntu is only for simulation. I hope you can offer me a solution. Thanks a lot!...

I used a translator, so that you can read more calmly, thanks for the suggestion to the person who wrote to me in another language outside of English, for my Chinese. Thank you, thank you!

- Lcvette

Probe Basic - ATC sim parameter question

Category: QtPyVCP

Chris

- Zubrze

- Zubrze

Rotary axis in Qtdragon_hd

Category: Qtvcp

"G-code previews should be done with zero G5x, G92 offsets. This can be facilitated by setting offsets in programs only when task is running as indicated by #<_task> == 1"

I understand the principle of this, but am not sure how to do it in practice! As I set the WCS offsets within the qtdragon_hd gui, how can I get those to only apply during running of the program? It seems like I would need to change the behavior of the GUI, but this is probably my misunderstanding. I'd appreciate greatly some step-by-step advice from someone who has gotten this working! Many thanks in advance!

- JT

- Rookie0

- Rookie0

Running halui in real time space?

Category: HAL

I wana make a webui controller like yours on youtube video, but I don't know how to connect websocket with nml.

I've not found any helpful nml's example code online.

Only one is: github.com/MachineryScience/Rockhopper

But it's too old, almost a dozen years ago, some code syntax has already reported errors.

I've never used nml before, and I took a brief look at the code, it doesn't seem to use nml.

I wonder your implementation method, or just show me your code, it's better if you don't mind ^_^

THANKS A LOT!

- lblabr

- lblabr

Raspberrypi 5 linuxcnc Image' screen resolution and color depth

Category: General LinuxCNC Questions

- lblabr

- lblabr

do - while | with time.0.minutes and time0.seconds

Category: G&M Codes

endless rotating cursor

it looks like that linuxcnc does somthing with the gcode (syntax check, duration calculation ??) can that swicthed off?

- MirkoCNC

- MirkoCNC

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

This error message is left:

loading board setup: Tangbob

loading toolchain gowin

writing gateware to: OutputTMP\Tangbob\Gateware

!!! gateware changed: needs to be build and flash |||

writing linuxcnc files to: OutputTMP\Tangbob\LinuxCNC

Der Befehl "C:\Users\MW\Downloads\riocore-using_os_path_join\riocore-using_os_path_join\bin\rio-generator" ist entweder falsch geschrieben oder

konnte nicht gefunden werden.

ERROR loading output: [Errno 2] No such file or directory: 'Output\\Tangbob\\Gateware\\rio.v'

PS C:\Users\MW\Downloads\riocore-using_os_path_join\riocore-using_os_path_join>

After pressing the button Generate it fails (dir OutputTMP can be created, but dir Output somehow not)

Any ideas on the rio-generator (directory is correct and rio-generator is there)?

- Sziggy_NC

- Sziggy_NC

7i92TF and c11g bin file

Category: Driver Boards

What I don't know how to do is create the bin file.

Is this something a typical end user can do?

- vibram

- vibram

Ethercat installation from repositories - how to step by step

Category: EtherCAT

however. I still get the same error message with apt ethercat and the mokutil --import

edit: I just rebooted and everything went through to the end, my modules are visible

thanks a lot for your quick support