Search Results (Searched for: )

- tcbmetalworks

- tcbmetalworks

17 Nov 2024 04:09

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

10.5 x 25 cnc plasma table retrofit

Category: Computers and Hardware

- tcbmetalworks

- tcbmetalworks

17 Nov 2024 03:57

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

10.5 x 25 cnc plasma table retrofit

Category: Computers and Hardware

- mBender

- mBender

17 Nov 2024 03:21

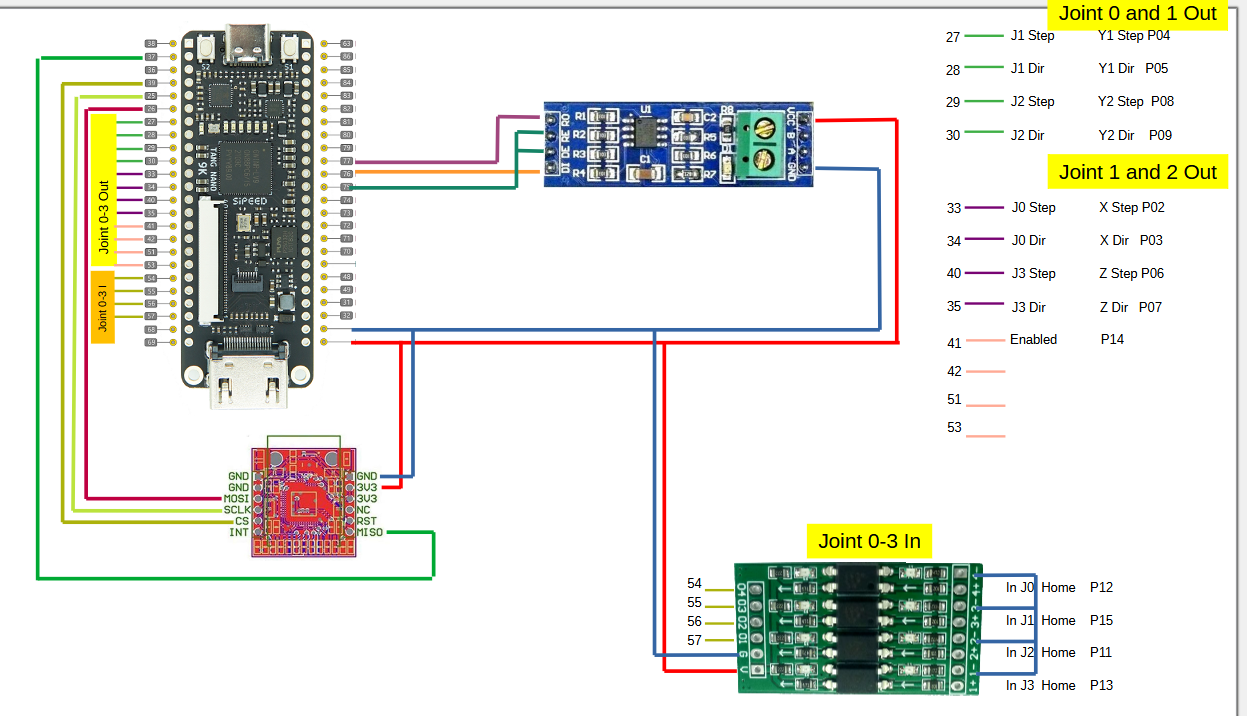

Replied by mBender on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- scotta

17 Nov 2024 02:41

Replied by scotta on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- digiex_chris

- digiex_chris

17 Nov 2024 02:23 - 17 Nov 2024 02:24

Replied by digiex_chris on topic Flex GUI Import a Python Module

Flex GUI Import a Python Module

Category: Other User Interfaces

- digiex_chris

- digiex_chris

17 Nov 2024 02:21

- IronManDylan

- IronManDylan

17 Nov 2024 02:10

Replied by IronManDylan on topic Fast Hole EDM from Hacked Parts

Fast Hole EDM from Hacked Parts

Category: General LinuxCNC Questions

- PCW

17 Nov 2024 00:29 - 17 Nov 2024 00:57

Replied by PCW on topic Strange motion offsets in one direction on one axis

Strange motion offsets in one direction on one axis

Category: General LinuxCNC Questions

- PCW

17 Nov 2024 00:12

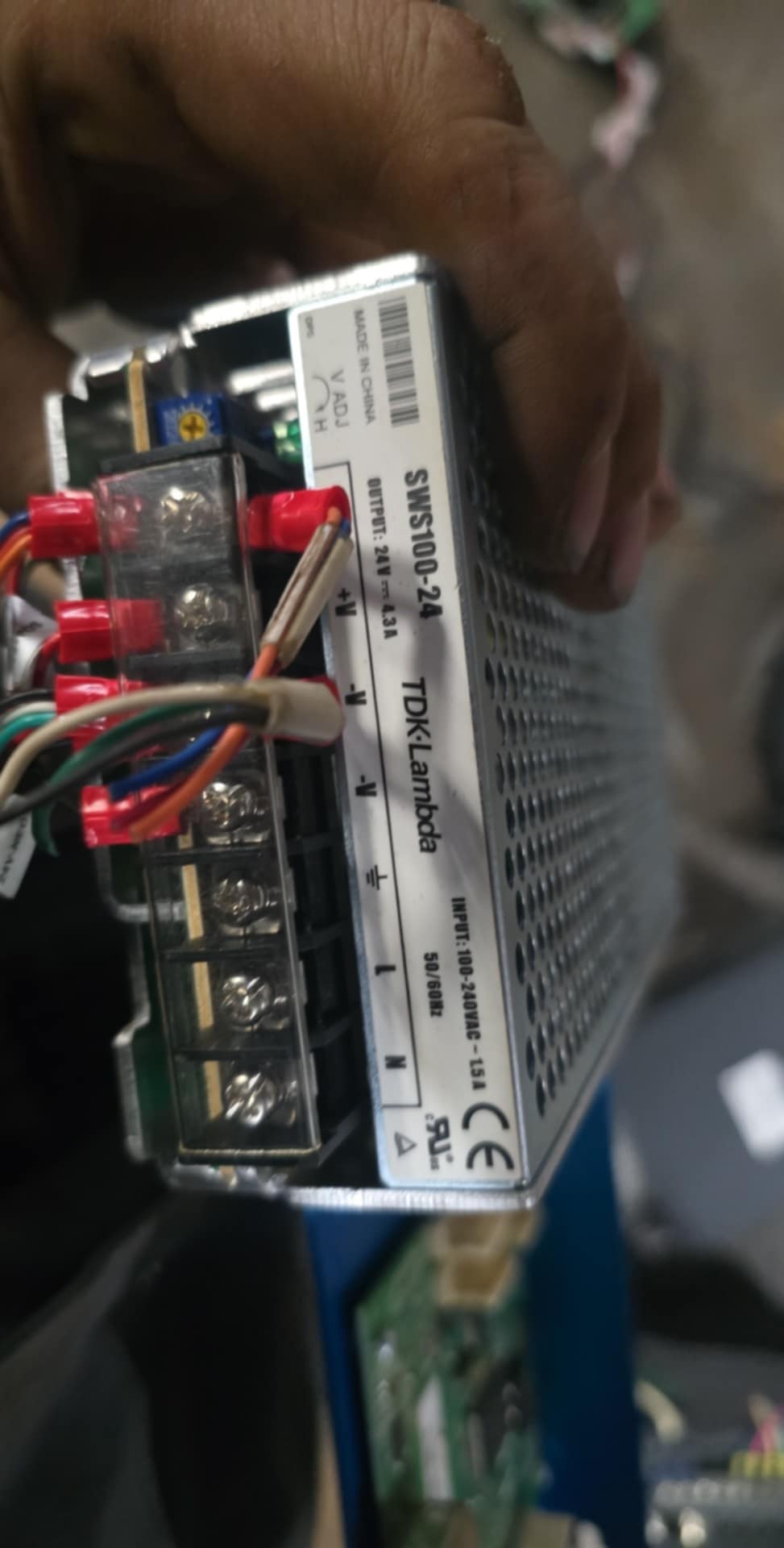

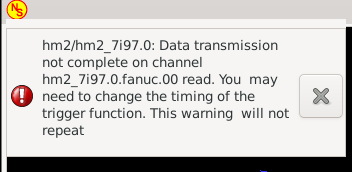

Replied by PCW on topic Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Category: Driver Boards

- Lcvette

17 Nov 2024 00:06

- dbtayl

- dbtayl

16 Nov 2024 23:07

Replied by dbtayl on topic Strange motion offsets in one direction on one axis

Strange motion offsets in one direction on one axis

Category: General LinuxCNC Questions

- Bennett

16 Nov 2024 23:04

Replied by Bennett on topic Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Category: Driver Boards

- tommylight

16 Nov 2024 22:30

Replied by tommylight on topic linux keeps restoring to an old workspace state after reboot

linux keeps restoring to an old workspace state after reboot

Category: General LinuxCNC Questions

- swanie2000

- swanie2000

16 Nov 2024 22:09

Replied by swanie2000 on topic Are there no increase/decrease spindle speed buttons in Gmoccapy?

Are there no increase/decrease spindle speed buttons in Gmoccapy?

Category: Gmoccapy

- Bennett

16 Nov 2024 21:39 - 16 Nov 2024 22:21

Replied by Bennett on topic Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Category: Driver Boards

Time to create page: 1.007 seconds