Search Results (Searched for: )

- trilobyte

- trilobyte

11 Nov 2024 11:48

Replied by trilobyte on topic Which Mesa Card Should I Buy?

Which Mesa Card Should I Buy?

Category: Driver Boards

- MaHa

- MaHa

11 Nov 2024 11:14

Replied by MaHa on topic Macro automatic tool length

Macro automatic tool length

Category: O Codes (subroutines) and NGCGUI

- Robbin

- Robbin

11 Nov 2024 09:08

- meister

- meister

11 Nov 2024 07:42

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- flexbex

- flexbex

11 Nov 2024 06:26

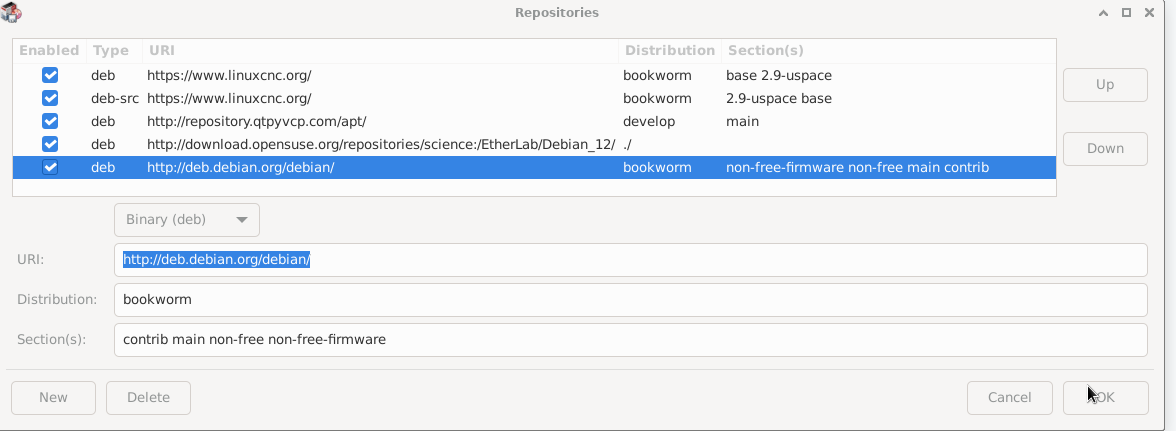

Help with source list was created by flexbex

Help with source list

Category: General LinuxCNC Questions

- angelnu

- angelnu

11 Nov 2024 05:12

Replied by angelnu on topic hm2/hm2_7i92.0: Error finishing read!

hm2/hm2_7i92.0: Error finishing read!

Category: Driver Boards

- smc.collins

- smc.collins

11 Nov 2024 03:13

- smc.collins

- smc.collins

11 Nov 2024 03:07

Replied by smc.collins on topic writing chip conveyor component , user input wanted

writing chip conveyor component , user input wanted

Category: HAL Examples

- cmorley

- cmorley

11 Nov 2024 02:10

- Sziggy_NC

- Sziggy_NC

11 Nov 2024 01:32

Replied by Sziggy_NC on topic +-10v setup 7i97 & .ini

+-10v setup 7i97 & .ini

Category: General LinuxCNC Questions

- Sziggy_NC

- Sziggy_NC

11 Nov 2024 01:21 - 14 Nov 2024 23:03

Replied by Sziggy_NC on topic +-10v setup 7i97 & .ini

+-10v setup 7i97 & .ini

Category: General LinuxCNC Questions

- greg23_78

- greg23_78

10 Nov 2024 23:22 - 10 Nov 2024 23:23

Macro automatic tool length was created by greg23_78

Macro automatic tool length

Category: O Codes (subroutines) and NGCGUI

- PCW

10 Nov 2024 22:45

Replied by PCW on topic +-10v setup 7i97 & .ini

+-10v setup 7i97 & .ini

Category: General LinuxCNC Questions

- Lcvette

10 Nov 2024 22:45

Replied by Lcvette on topic probe basic - toolpath/file preview loading error

probe basic - toolpath/file preview loading error

Category: QtPyVCP

- Sziggy_NC

- Sziggy_NC

10 Nov 2024 22:04

+-10v setup 7i97 & .ini was created by Sziggy_NC

+-10v setup 7i97 & .ini

Category: General LinuxCNC Questions

Time to create page: 0.427 seconds