Search Results (Searched for: )

- meister

- meister

04 Jul 2025 19:47

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- PCW

04 Jul 2025 19:44

Replied by PCW on topic [Solved] Mesa 7i96 Spindle PWM

[Solved] Mesa 7i96 Spindle PWM

Category: Driver Boards

- Aciera

04 Jul 2025 19:20

- whyme

- whyme

04 Jul 2025 18:59 - 04 Jul 2025 20:19

Replied by whyme on topic Raspberry Pi 4 with Mesa 7c81

Raspberry Pi 4 with Mesa 7c81

Category: Driver Boards

- ziggi

04 Jul 2025 18:46 - 04 Jul 2025 20:42

Replied by ziggi on topic Troubles to get started with SD240 Retrofit

Troubles to get started with SD240 Retrofit

Category: Turning

- dubstar_04

04 Jul 2025 18:23

Replied by dubstar_04 on topic [Solved] Mesa 7i96 Spindle PWM

[Solved] Mesa 7i96 Spindle PWM

Category: Driver Boards

- Johnnysacalu

- Johnnysacalu

04 Jul 2025 18:23

Replied by Johnnysacalu on topic Lo ejes dejaron de moverse

Lo ejes dejaron de moverse

Category: General LinuxCNC Questions

- steers

- steers

04 Jul 2025 18:16

looking for advice on retrofitting hydrolic mill was created by steers

looking for advice on retrofitting hydrolic mill

Category: Driver Boards

- HansU

04 Jul 2025 18:12

- PCW

04 Jul 2025 18:07 - 04 Jul 2025 18:14

Replied by PCW on topic [Solved] Mesa 7i96 Spindle PWM

[Solved] Mesa 7i96 Spindle PWM

Category: Driver Boards

- dubstar_04

04 Jul 2025 17:15

Replied by dubstar_04 on topic [Solved] Mesa 7i96 Spindle PWM

[Solved] Mesa 7i96 Spindle PWM

Category: Driver Boards

- PCW

04 Jul 2025 17:06

Replied by PCW on topic [Solved] Mesa 7i96 Spindle PWM

[Solved] Mesa 7i96 Spindle PWM

Category: Driver Boards

- dubstar_04

04 Jul 2025 16:53

Replied by dubstar_04 on topic [Solved] Mesa 7i96 Spindle PWM

[Solved] Mesa 7i96 Spindle PWM

Category: Driver Boards

- Sternfox

- Sternfox

04 Jul 2025 16:38

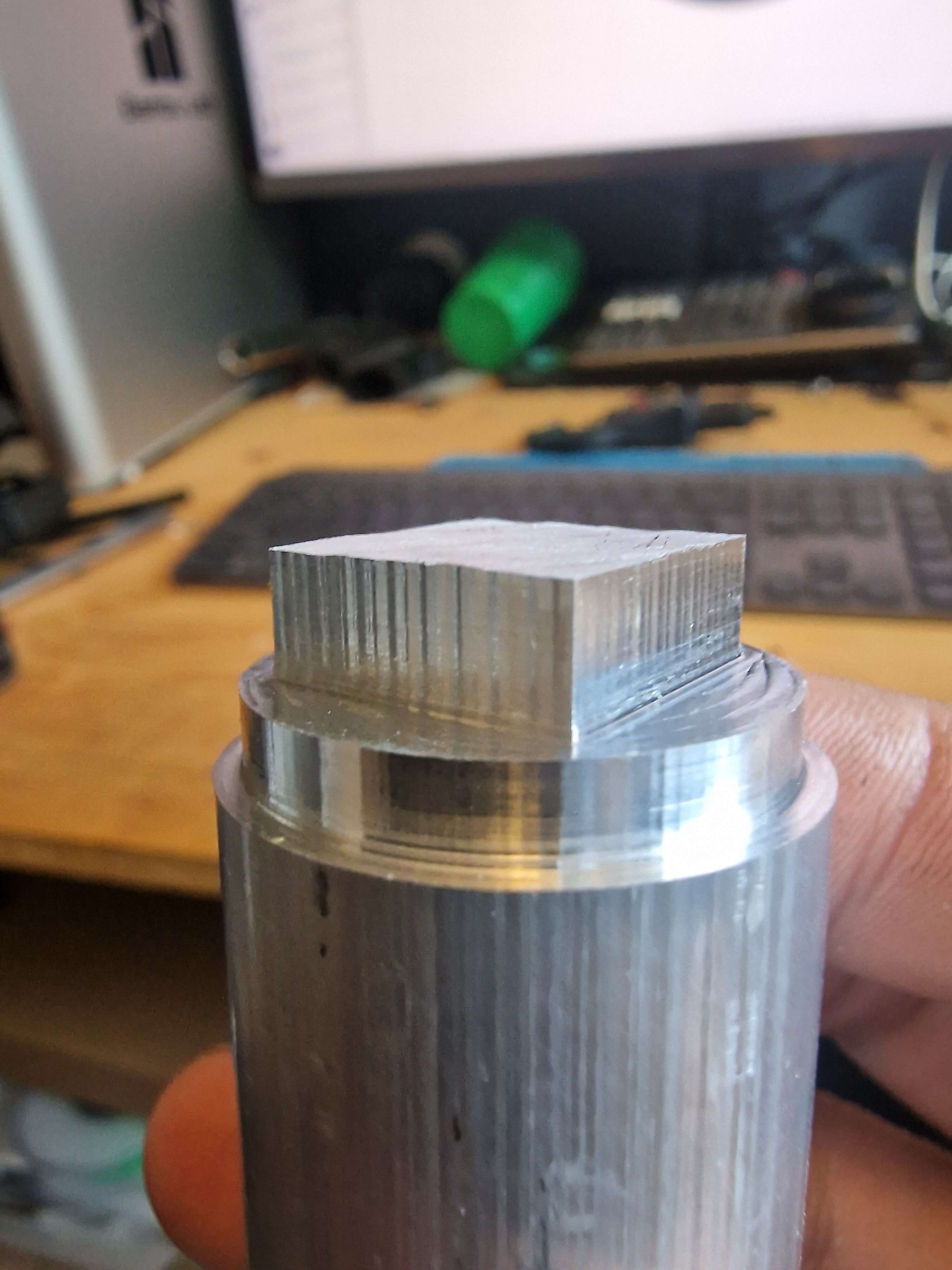

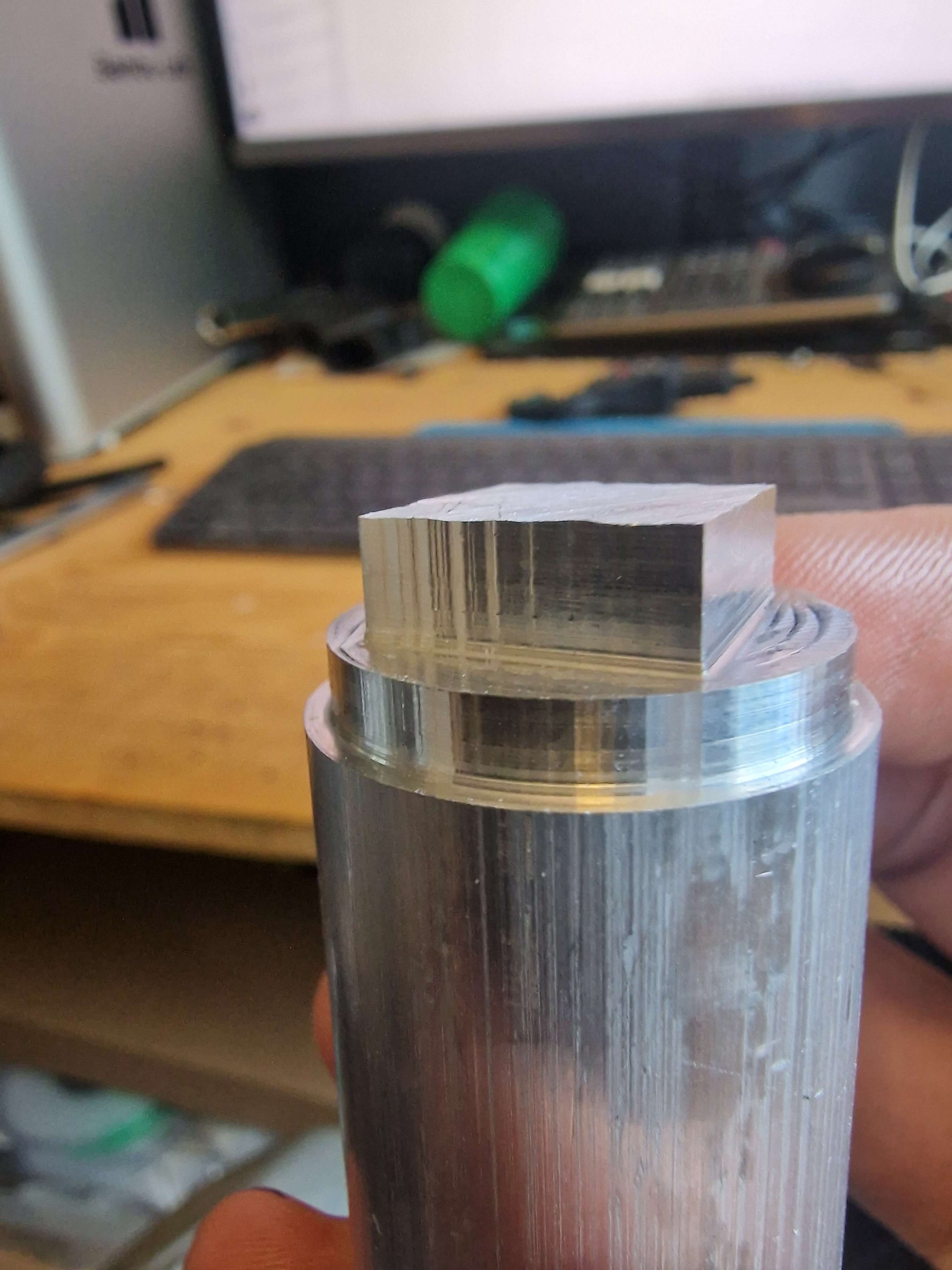

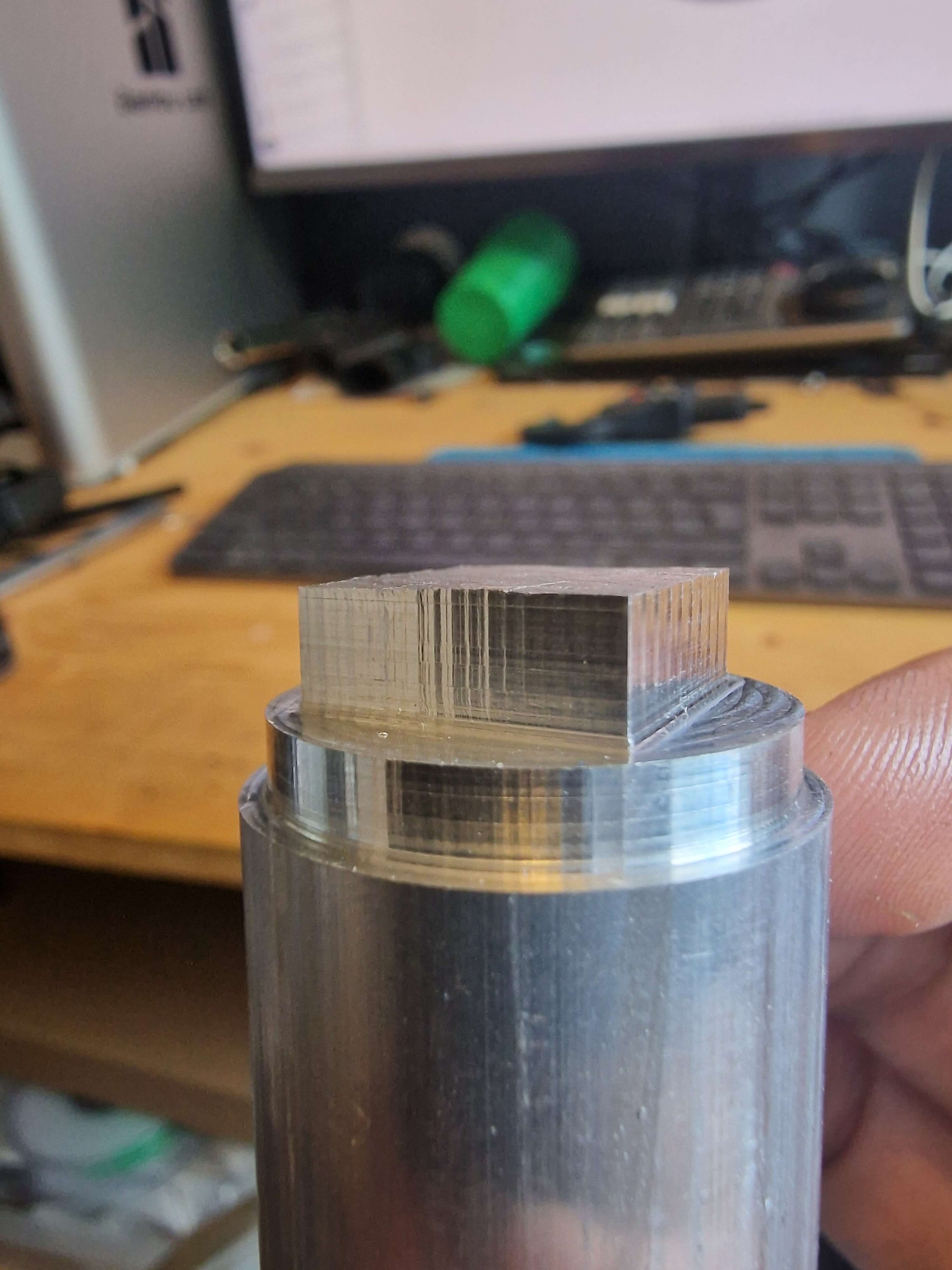

poor surface quality was created by Sternfox

poor surface quality

Category: General LinuxCNC Questions

- PCW

04 Jul 2025 16:16

Replied by PCW on topic [Solved] Mesa 7i96 Spindle PWM

[Solved] Mesa 7i96 Spindle PWM

Category: Driver Boards

Time to create page: 0.646 seconds