Search Results (Searched for: )

- spumco

- spumco

03 Jun 2025 01:11

Replied by spumco on topic GUI that somewhat resembles haas or fanuc workflow.

GUI that somewhat resembles haas or fanuc workflow.

Category: General LinuxCNC Questions

- langdons

- langdons

03 Jun 2025 00:47

Replied by langdons on topic EasyProbe + PGFUN 3D probe

EasyProbe + PGFUN 3D probe

Category: General LinuxCNC Questions

- langdons

- langdons

03 Jun 2025 00:44

Replied by langdons on topic Position: relative expected

Position: relative expected

Category: General LinuxCNC Questions

- langdons

- langdons

03 Jun 2025 00:43

Replied by langdons on topic GUI that somewhat resembles haas or fanuc workflow.

GUI that somewhat resembles haas or fanuc workflow.

Category: General LinuxCNC Questions

- langdons

- langdons

03 Jun 2025 00:35 - 03 Jun 2025 00:35

Replied by langdons on topic GUI that somewhat resembles haas or fanuc workflow.

GUI that somewhat resembles haas or fanuc workflow.

Category: General LinuxCNC Questions

- tommylight

02 Jun 2025 23:25

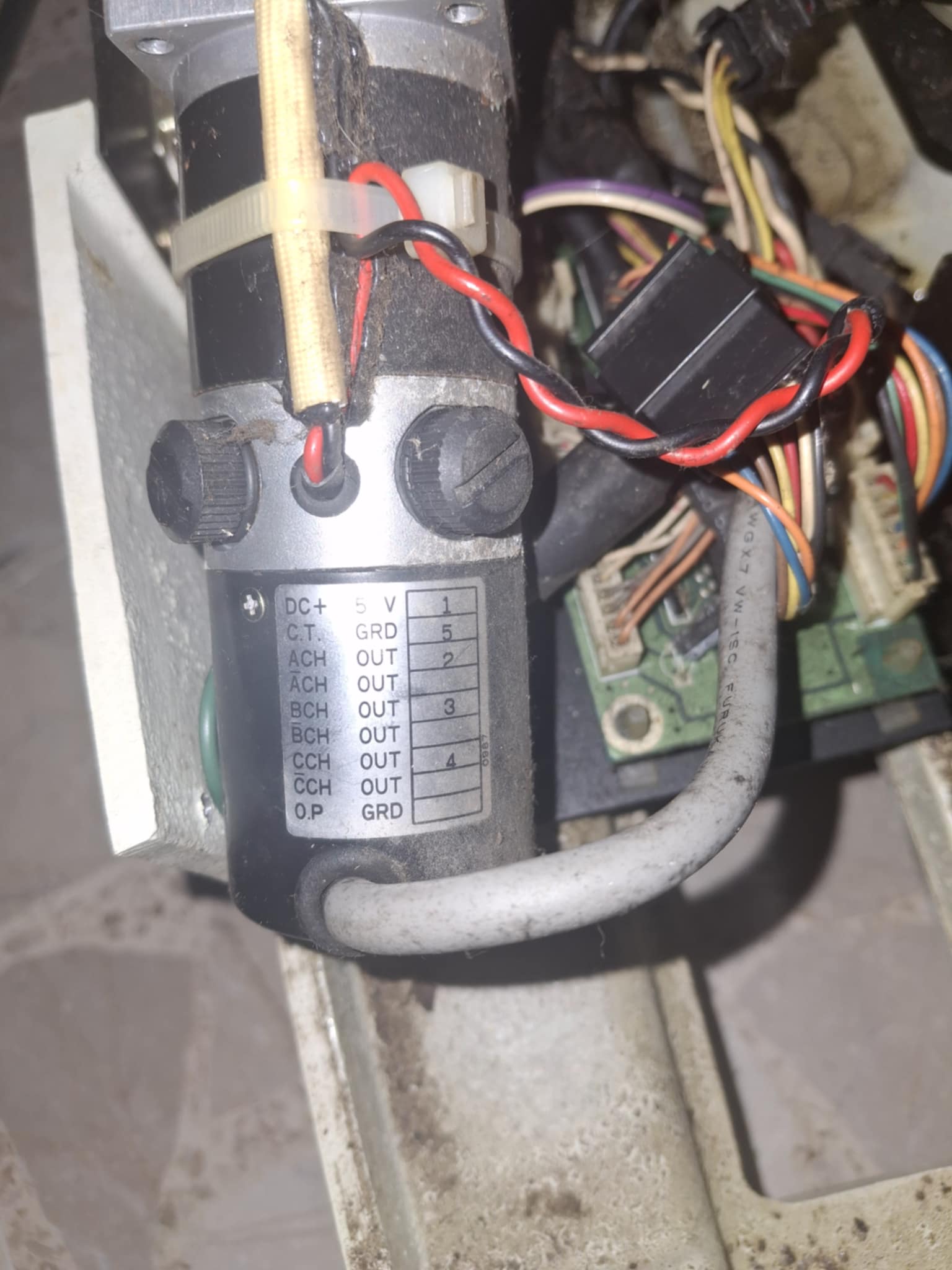

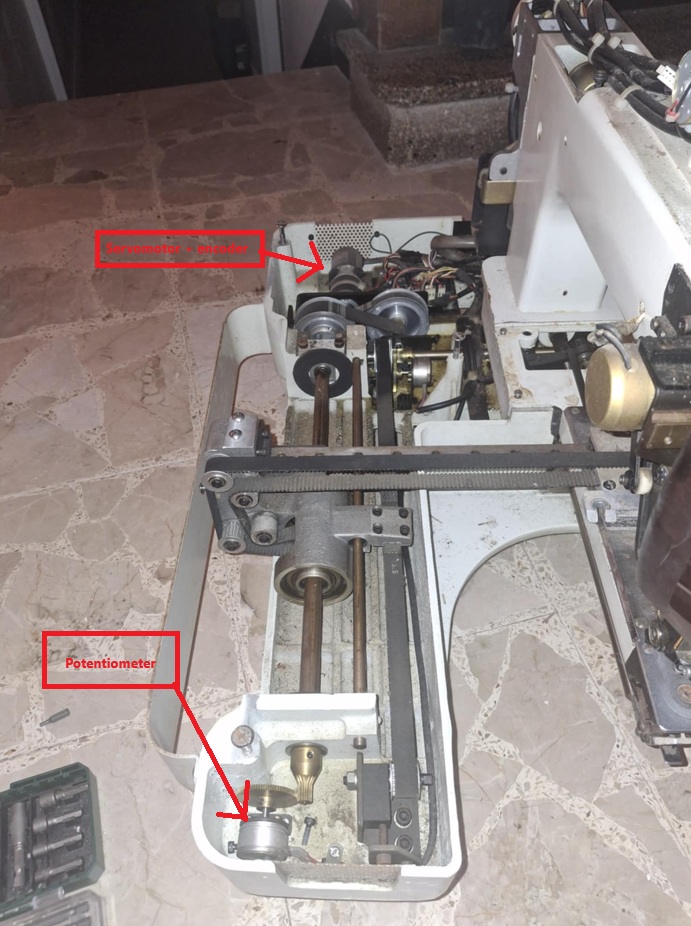

Replied by tommylight on topic Toyota embroidery machine - retrofit

Toyota embroidery machine - retrofit

Category: CNC Machines

- atrex77

02 Jun 2025 23:18

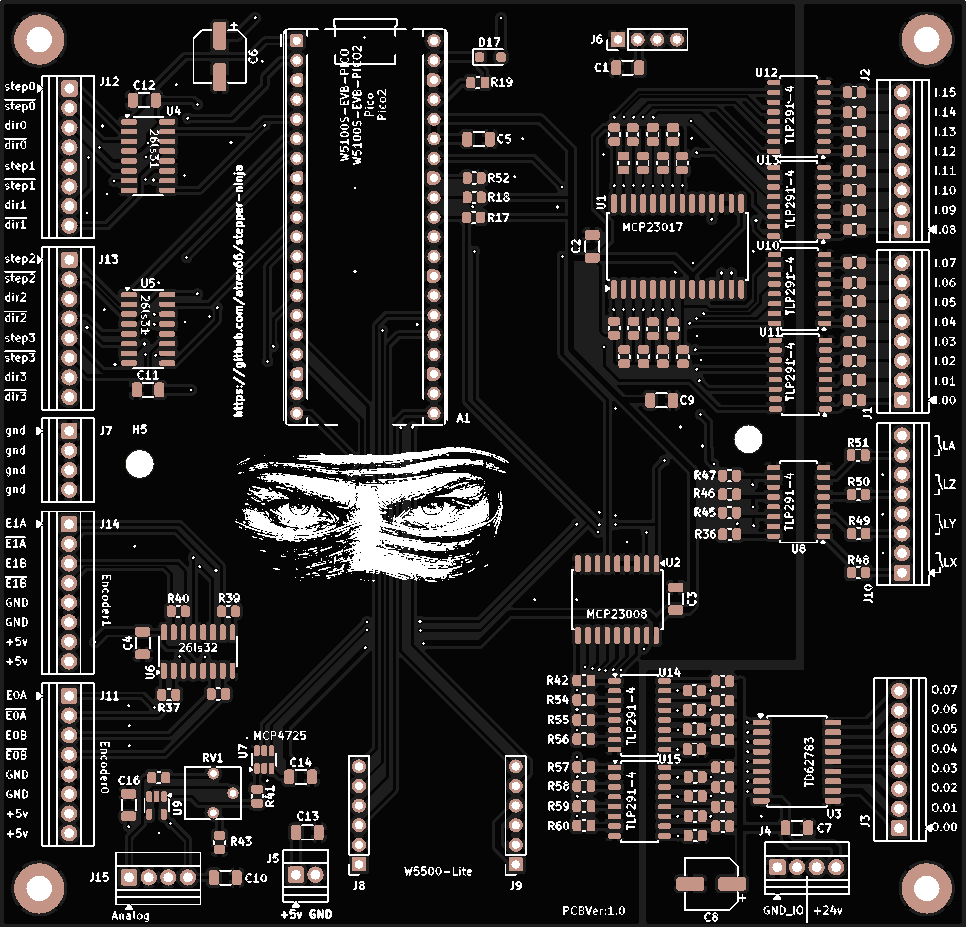

Replied by atrex77 on topic W5100S-EVB-PICO stepgenerator and encoder driver

W5100S-EVB-PICO stepgenerator and encoder driver

Category: Driver Boards

- PCW

02 Jun 2025 22:29

Replied by PCW on topic Toyota embroidery machine - retrofit

Toyota embroidery machine - retrofit

Category: CNC Machines

- spumco

- spumco

02 Jun 2025 22:23

Replied by spumco on topic GUI that somewhat resembles haas or fanuc workflow.

GUI that somewhat resembles haas or fanuc workflow.

Category: General LinuxCNC Questions

- greg23_78

- greg23_78

02 Jun 2025 22:07 - 02 Jun 2025 22:09

Toyota embroidery machine - retrofit was created by greg23_78

Toyota embroidery machine - retrofit

Category: CNC Machines

- richcolvin

02 Jun 2025 22:04

Getting Started with GladeVCP was created by richcolvin

Getting Started with GladeVCP

Category: AXIS

- PCW

02 Jun 2025 21:38

Replied by PCW on topic Mesa card issues Maho MH800E Retrofit Project

Mesa card issues Maho MH800E Retrofit Project

Category: Computers and Hardware

- Cooped-Up

- Cooped-Up

02 Jun 2025 20:51

Replied by Cooped-Up on topic Mesa card issues Maho MH800E Retrofit Project

Mesa card issues Maho MH800E Retrofit Project

Category: Computers and Hardware

- theoneandonlyoreo

- theoneandonlyoreo

02 Jun 2025 20:30 - 03 Jun 2025 21:51

Replied by theoneandonlyoreo on topic EasyProbe + PGFUN 3D probe

EasyProbe + PGFUN 3D probe

Category: General LinuxCNC Questions

- PCW

02 Jun 2025 20:24

Time to create page: 0.321 seconds