Search Results (Searched for: )

- Cant do this anymore bye all

16 Jul 2024 22:38

Replied by Cant do this anymore bye all on topic Dimensions Slightly Off

Dimensions Slightly Off

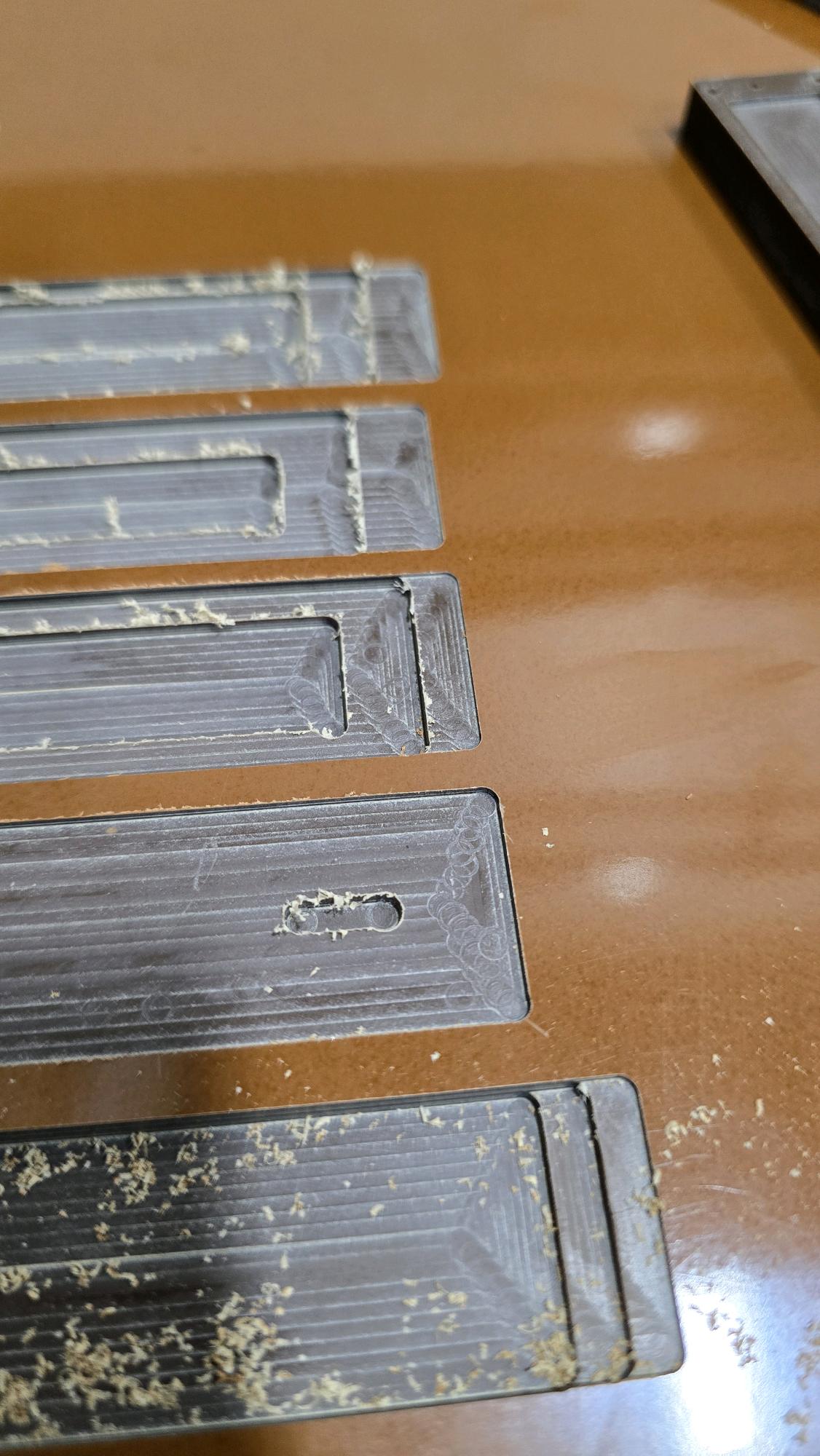

Category: Milling Machines

- sandersjrs

- sandersjrs

16 Jul 2024 22:17

Replied by sandersjrs on topic Dimensions Slightly Off

Dimensions Slightly Off

Category: Milling Machines

- my1987toyota

16 Jul 2024 22:04

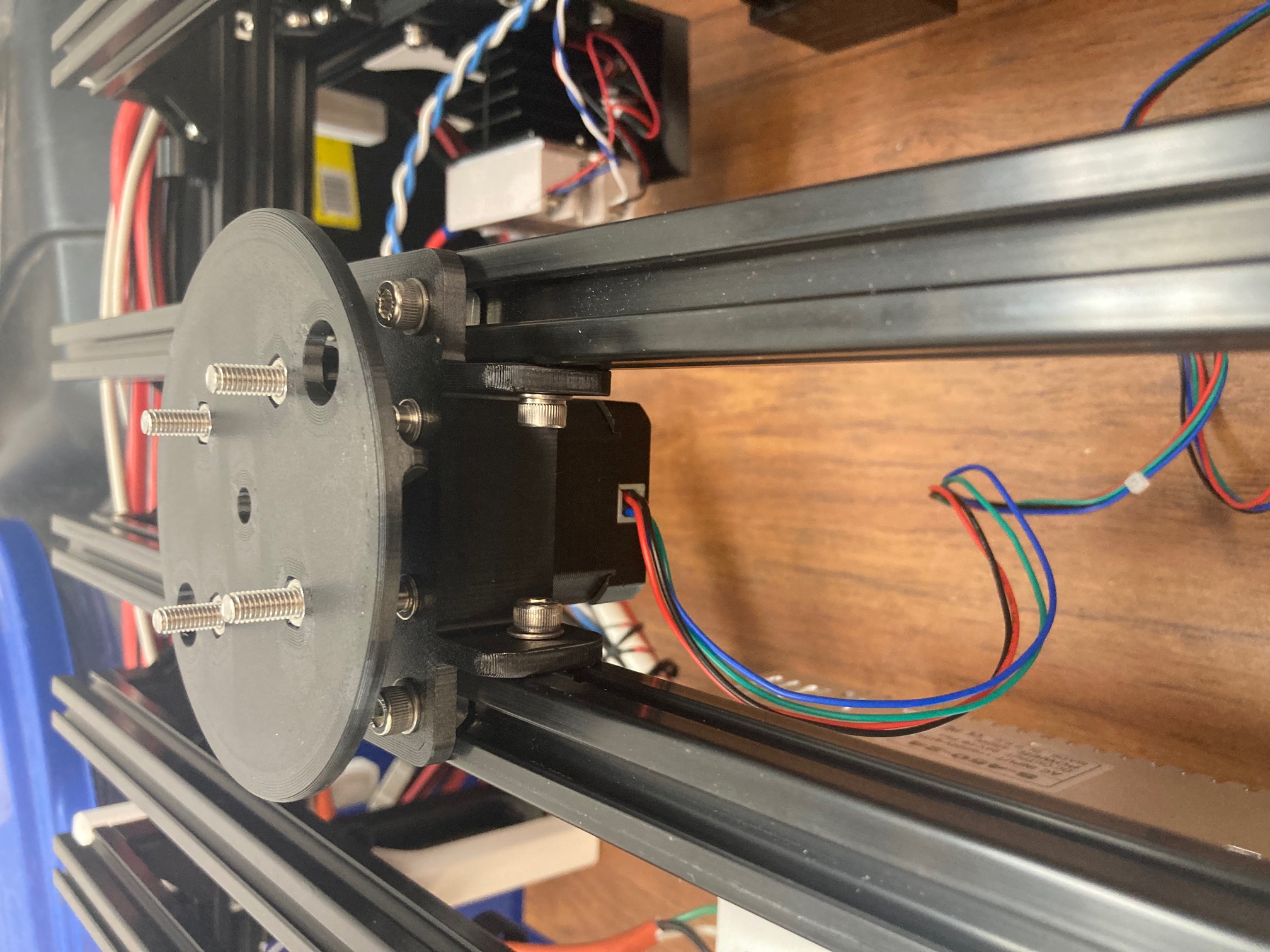

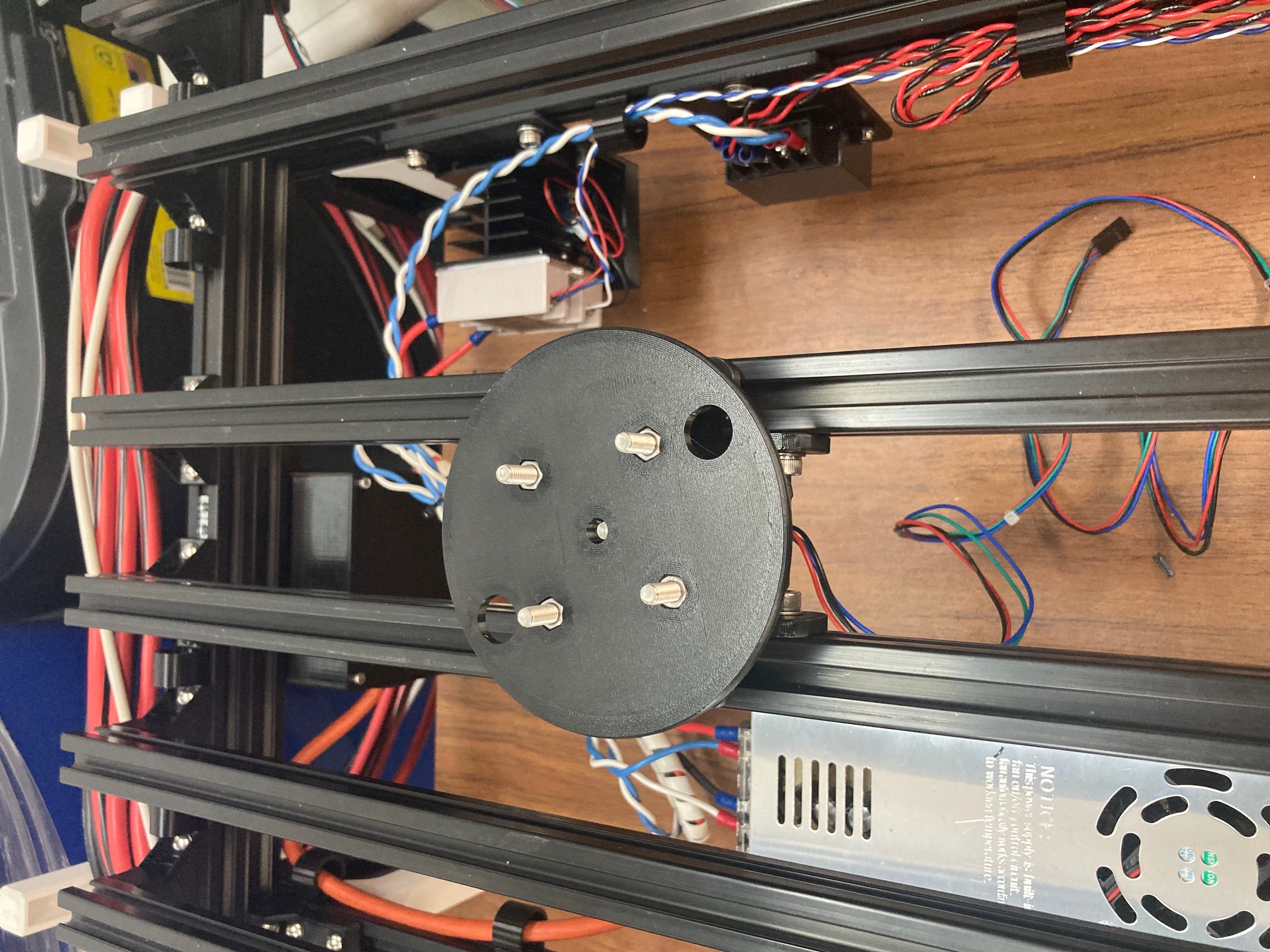

Replied by my1987toyota on topic Mostly 3D Printed CNC Foam cutter

Mostly 3D Printed CNC Foam cutter

Category: CNC Machines

- my1987toyota

16 Jul 2024 22:01 - 16 Jul 2024 22:02

Replied by my1987toyota on topic Mostly 3D Printed CNC Foam cutter

Mostly 3D Printed CNC Foam cutter

Category: CNC Machines

- ihavenofish

- ihavenofish

16 Jul 2024 21:45

Replied by ihavenofish on topic Mini wannabe datron build

Mini wannabe datron build

Category: CNC Machines

- PCW

16 Jul 2024 21:40

Replied by PCW on topic Help understanding fundamentals of linuxcnc

Help understanding fundamentals of linuxcnc

Category: General LinuxCNC Questions

- ihavenofish

- ihavenofish

16 Jul 2024 21:35

Replied by ihavenofish on topic Mini wannabe datron build

Mini wannabe datron build

Category: CNC Machines

- rodw

16 Jul 2024 21:35

- thomaseg

- thomaseg

16 Jul 2024 21:26

Safety relay and e-stop in LCNC? was created by thomaseg

Safety relay and e-stop in LCNC?

Category: Basic Configuration

- Caffink

- Caffink

16 Jul 2024 21:24

Replied by Caffink on topic Help understanding fundamentals of linuxcnc

Help understanding fundamentals of linuxcnc

Category: General LinuxCNC Questions

- PCW

16 Jul 2024 21:24

Replied by PCW on topic Help understanding fundamentals of linuxcnc

Help understanding fundamentals of linuxcnc

Category: General LinuxCNC Questions

- rodw

16 Jul 2024 21:21

Replied by rodw on topic Help understanding fundamentals of linuxcnc

Help understanding fundamentals of linuxcnc

Category: General LinuxCNC Questions

- spumco

- spumco

16 Jul 2024 21:20

Replied by spumco on topic Mini wannabe datron build

Mini wannabe datron build

Category: CNC Machines

- rodw

16 Jul 2024 21:18

Replied by rodw on topic emc.hh -- hal_priv.hh --- etc etc not find

emc.hh -- hal_priv.hh --- etc etc not find

Category: HAL

- Caffink

- Caffink

16 Jul 2024 21:09

Replied by Caffink on topic Help understanding fundamentals of linuxcnc

Help understanding fundamentals of linuxcnc

Category: General LinuxCNC Questions

Time to create page: 0.586 seconds