Search Results (Searched for: )

- gardenweazel

02 Nov 2025 19:57

Replied by gardenweazel on topic Motor Driver Electrical Question

Motor Driver Electrical Question

Category: Basic Configuration

- Pinaz993

- Pinaz993

02 Nov 2025 19:53

Usable Interface for CNC Turntable on Manual Mill was created by Pinaz993

Usable Interface for CNC Turntable on Manual Mill

Category: Other User Interfaces

- conman

- conman

02 Nov 2025 19:15

Replied by conman on topic Help with Inovance IS620N Servo Drive - Stays in PREOP

Help with Inovance IS620N Servo Drive - Stays in PREOP

Category: EtherCAT

- john.obrien

- john.obrien

02 Nov 2025 19:09

A suggestion for the 7i76 documentation was created by john.obrien

A suggestion for the 7i76 documentation

Category: Driver Boards

- conman

- conman

02 Nov 2025 19:03

Replied by conman on topic Help with Inovance IS620N Servo Drive - Stays in PREOP

Help with Inovance IS620N Servo Drive - Stays in PREOP

Category: EtherCAT

- langdons

02 Nov 2025 17:41 - 02 Nov 2025 17:48

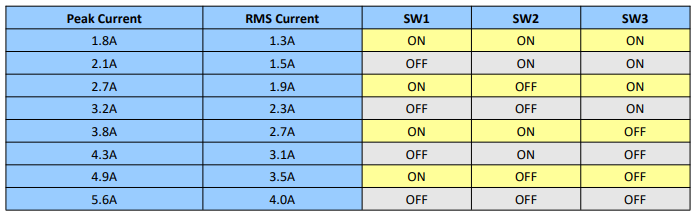

Replied by langdons on topic Motor Driver Electrical Question

Motor Driver Electrical Question

Category: Basic Configuration

- langdons

02 Nov 2025 17:33

Replied by langdons on topic Motor Driver Electrical Question

Motor Driver Electrical Question

Category: Basic Configuration

- CADdy

02 Nov 2025 17:16

- snowgoer540

02 Nov 2025 17:11

Replied by snowgoer540 on topic Laser Button Doesn't toggle to mark edge and origin

Laser Button Doesn't toggle to mark edge and origin

Category: Plasmac

- unknown

- unknown

02 Nov 2025 17:09

- CADdy

02 Nov 2025 16:37 - 02 Nov 2025 16:44

- Aciera

02 Nov 2025 16:25 - 02 Nov 2025 16:32

Replied by Aciera on topic Try to activate Gladevcp with setp gladevcp -> Linuxcnc

Try to activate Gladevcp with setp gladevcp -> Linuxcnc

Category: GladeVCP

- PCW

02 Nov 2025 16:15

Replied by PCW on topic Mesa sserial cards combination for 3 analog servos + I/O

Mesa sserial cards combination for 3 analog servos + I/O

Category: Driver Boards

- kostas

02 Nov 2025 16:11

Replied by kostas on topic Mesa sserial cards combination for 3 analog servos + I/O

Mesa sserial cards combination for 3 analog servos + I/O

Category: Driver Boards

- gardenweazel

02 Nov 2025 16:08

Motor Driver Electrical Question was created by gardenweazel

Motor Driver Electrical Question

Category: Basic Configuration

Time to create page: 0.296 seconds