Search Results (Searched for: )

- GeckoWorks

- GeckoWorks

21 Nov 2024 13:19

Replied by GeckoWorks on topic Index homing Mesa 7i96s

Index homing Mesa 7i96s

Category: PnCConf Wizard

- sk_linuxcnc

- sk_linuxcnc

21 Nov 2024 10:28

Replied by sk_linuxcnc on topic Help: How to run X and A axis with different feed rates simultaneously?

Help: How to run X and A axis with different feed rates simultaneously?

Category: G&M Codes

- Aciera

21 Nov 2024 10:22

Replied by Aciera on topic Help: How to run X and A axis with different feed rates simultaneously?

Help: How to run X and A axis with different feed rates simultaneously?

Category: G&M Codes

- sk_linuxcnc

- sk_linuxcnc

21 Nov 2024 09:48

Replied by sk_linuxcnc on topic Help: How to run X and A axis with different feed rates simultaneously?

Help: How to run X and A axis with different feed rates simultaneously?

Category: G&M Codes

- sk_linuxcnc

- sk_linuxcnc

21 Nov 2024 09:43

Replied by sk_linuxcnc on topic Help: How to run X and A axis with different feed rates simultaneously?

Help: How to run X and A axis with different feed rates simultaneously?

Category: G&M Codes

- sk_linuxcnc

- sk_linuxcnc

21 Nov 2024 09:34

Replied by sk_linuxcnc on topic Help: configure a Servo motor with (PUL/DIR) as a Spindle by Par-port stepconfig

Help: configure a Servo motor with (PUL/DIR) as a Spindle by Par-port stepconfig

Category: StepConf Wizard

- nigelh

21 Nov 2024 09:27

Replied by nigelh on topic System homes but unresponsive

System homes but unresponsive

Category: Installing LinuxCNC

- tcbmetalworks

- tcbmetalworks

21 Nov 2024 08:44

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

10.5 x 25 cnc plasma table retrofit

Category: Computers and Hardware

- Aciera

21 Nov 2024 08:43

Replied by Aciera on topic Classic Ladder not working with LinuxCNC Rio

Classic Ladder not working with LinuxCNC Rio

Category: ClassicLadder

- tcbmetalworks

- tcbmetalworks

21 Nov 2024 08:32

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

10.5 x 25 cnc plasma table retrofit

Category: Computers and Hardware

- Hossein74Majidi

- Hossein74Majidi

21 Nov 2024 08:31

Replied by Hossein74Majidi on topic Real-Time Kernel with Orange Pi 4 LTS

Real-Time Kernel with Orange Pi 4 LTS

Category: General LinuxCNC Questions

- Aciera

21 Nov 2024 08:04 - 21 Nov 2024 08:25

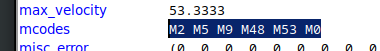

Replied by Aciera on topic How to detect M0 pause?

How to detect M0 pause?

Category: Other User Interfaces

- Aciera

21 Nov 2024 07:26

Replied by Aciera on topic Are there no increase/decrease spindle speed buttons in Gmoccapy?

Are there no increase/decrease spindle speed buttons in Gmoccapy?

Category: Gmoccapy

- NTULINUX

21 Nov 2024 06:06 - 21 Nov 2024 06:15

Replied by NTULINUX on topic Best version for Parport machine and how to install

Best version for Parport machine and how to install

Category: Installing LinuxCNC

- GeckoWorks

- GeckoWorks

21 Nov 2024 04:13 - 21 Nov 2024 04:14

Replied by GeckoWorks on topic Index homing Mesa 7i96s

Index homing Mesa 7i96s

Category: PnCConf Wizard

Time to create page: 0.376 seconds