Search Results (Searched for: )

- COFHAL

- COFHAL

16 Dec 2025 00:31

Replied by COFHAL on topic Adding second spindle control to pyVCP: is it complicated?

Adding second spindle control to pyVCP: is it complicated?

Category: pyVCP

- COFHAL

- COFHAL

16 Dec 2025 00:28

Replied by COFHAL on topic Physical buttons to 7i96s+7i77

Physical buttons to 7i96s+7i77

Category: HAL

- nanowhat

- nanowhat

15 Dec 2025 23:51

Replied by nanowhat on topic Ethercat drives not responding, mesa error finishing read

Ethercat drives not responding, mesa error finishing read

Category: EtherCAT

- nanowhat

- nanowhat

15 Dec 2025 23:43

- Hakan

- Hakan

15 Dec 2025 23:38

Replied by Hakan on topic Long initialization of Ethercat on servo drive SV660N

Long initialization of Ethercat on servo drive SV660N

Category: EtherCAT

- djdelorie

- djdelorie

15 Dec 2025 22:30

Replied by djdelorie on topic VOLATILE_HOME not unhoming on fault

VOLATILE_HOME not unhoming on fault

Category: Basic Configuration

- NWE

- NWE

15 Dec 2025 22:19 - 15 Dec 2025 22:39

- NWE

- NWE

15 Dec 2025 22:04 - 15 Dec 2025 22:18

- tommylight

15 Dec 2025 21:52

Replied by tommylight on topic Advantech PCM 9362 freze when opening latency-test

Advantech PCM 9362 freze when opening latency-test

Category: Computers and Hardware

- tommylight

15 Dec 2025 21:49

Replied by tommylight on topic VOLATILE_HOME not unhoming on fault

VOLATILE_HOME not unhoming on fault

Category: Basic Configuration

- NWE

- NWE

15 Dec 2025 21:44

- alangibson

- alangibson

15 Dec 2025 20:24

- djdelorie

- djdelorie

15 Dec 2025 20:15

Replied by djdelorie on topic VOLATILE_HOME not unhoming on fault

VOLATILE_HOME not unhoming on fault

Category: Basic Configuration

- djdelorie

- djdelorie

15 Dec 2025 20:12

Replied by djdelorie on topic VOLATILE_HOME not unhoming on fault

VOLATILE_HOME not unhoming on fault

Category: Basic Configuration

- Sekai

- Sekai

15 Dec 2025 20:07

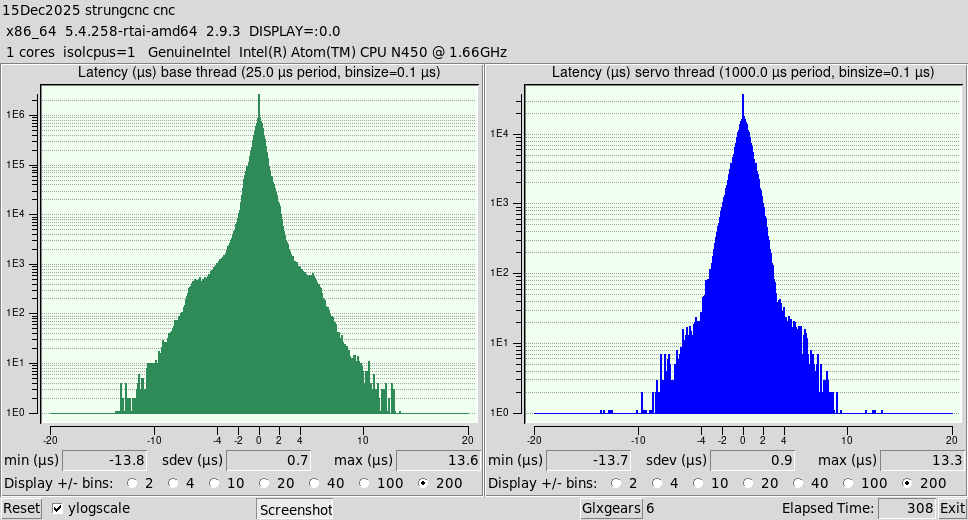

Advantech PCM 9362 freze when opening latency-test was created by Sekai

Advantech PCM 9362 freze when opening latency-test

Category: Computers and Hardware

Time to create page: 0.269 seconds