Search Results (Searched for: )

- PCW

14 May 2024 15:37

- zajc3w

- zajc3w

14 May 2024 15:08 - 14 May 2024 15:13

- westhedge

- westhedge

14 May 2024 15:00

Replied by westhedge on topic XHC-WHB04B-6 and LinuxCNC 2.9.1

XHC-WHB04B-6 and LinuxCNC 2.9.1

Category: Installing LinuxCNC

- CNC-Martin

14 May 2024 14:44

Replied by CNC-Martin on topic Retrofit cnc plasma help needed desperately

Retrofit cnc plasma help needed desperately

Category: Installing LinuxCNC

- PCW

14 May 2024 13:31

Replied by PCW on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- Aciera

14 May 2024 12:29 - 14 May 2024 12:45

- TangentAudio

- TangentAudio

14 May 2024 11:58

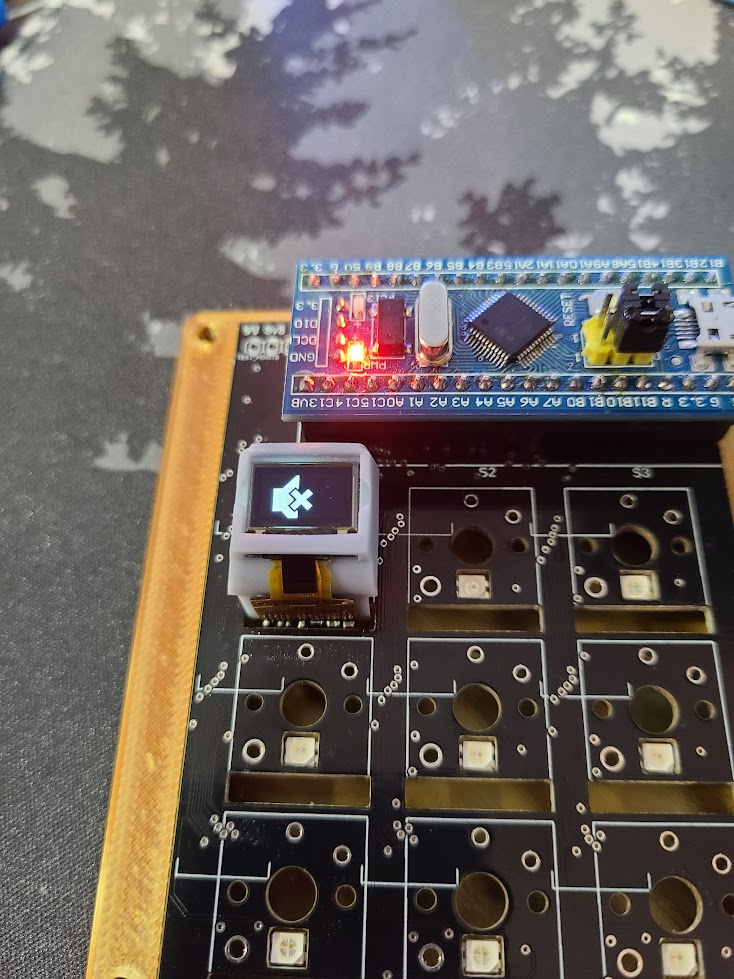

Replied by TangentAudio on topic Announcing Deckard: StreamDeck support for LinuxCNC

Announcing Deckard: StreamDeck support for LinuxCNC

Category: Show Your Stuff

- tommylight

14 May 2024 11:16

Replied by tommylight on topic Retrofit cnc plasma help needed desperately

Retrofit cnc plasma help needed desperately

Category: Installing LinuxCNC

- N3pu

- N3pu

14 May 2024 11:13

- StoneB

- StoneB

14 May 2024 11:13 - 14 May 2024 11:19

Replied by StoneB on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- tommylight

14 May 2024 11:12

Replied by tommylight on topic Run linuxcnc as root user

Run linuxcnc as root user

Category: General LinuxCNC Questions

- anfänger

14 May 2024 09:41

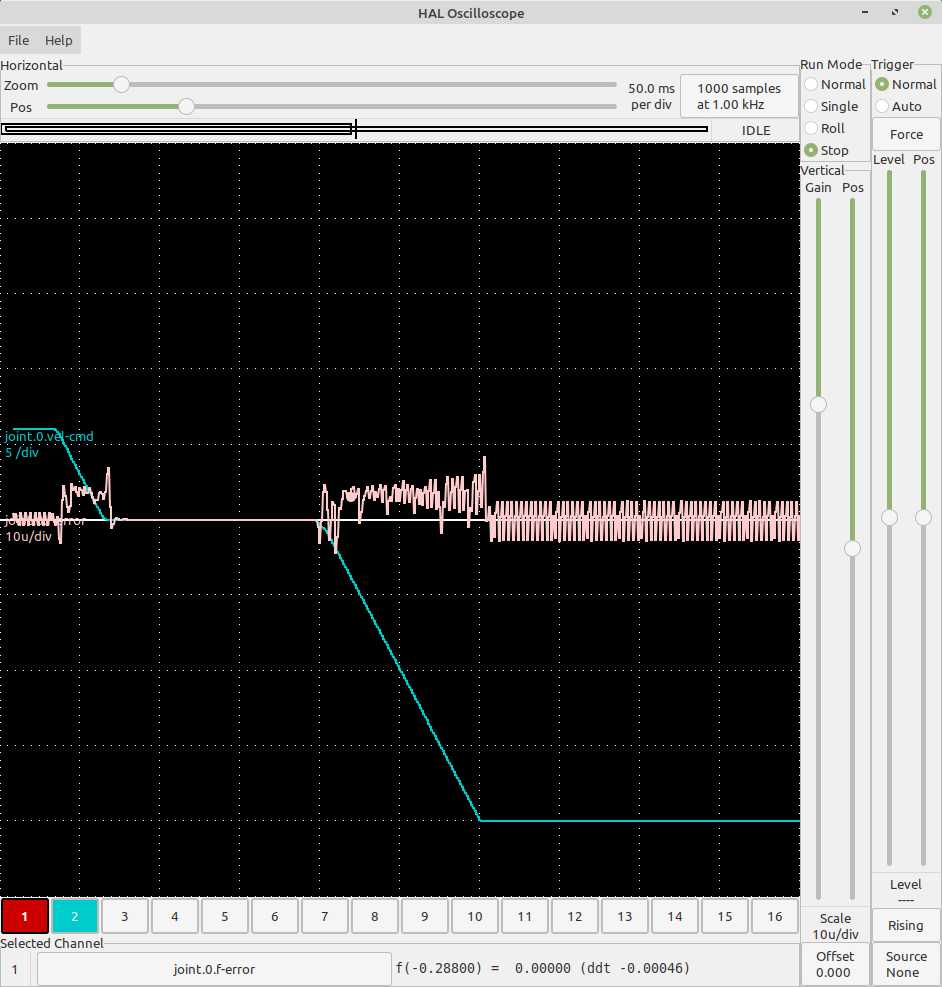

Replied by anfänger on topic Mesa Analog Vs Step Dir

Mesa Analog Vs Step Dir

Category: Driver Boards

- timaer

- timaer

14 May 2024 09:34

Replied by timaer on topic Is QtVCP better than QtPyVCP ?

Is QtVCP better than QtPyVCP ?

Category: QtPyVCP

- Aciera

14 May 2024 09:31

Replied by Aciera on topic Is QtVCP better than QtPyVCP ?

Is QtVCP better than QtPyVCP ?

Category: QtPyVCP

- timaer

- timaer

14 May 2024 09:13

Replied by timaer on topic Is QtVCP better than QtPyVCP ?

Is QtVCP better than QtPyVCP ?

Category: QtPyVCP

Time to create page: 0.945 seconds