Search Results (Searched for: )

- small panda

- small panda

27 Dec 2025 06:09

Replied by small panda on topic Request to add a Chinese section

Request to add a Chinese section

Category: Other Languages

- NWE

27 Dec 2025 06:02 - 27 Dec 2025 06:19

Replied by NWE on topic Recommend hardware solution for multi rs485 channel?

Recommend hardware solution for multi rs485 channel?

Category: Computers and Hardware

- unknown

- unknown

27 Dec 2025 05:47

- PCW

27 Dec 2025 04:47

- heaven

- heaven

27 Dec 2025 04:10

Recommend hardware solution for multi rs485 channel? was created by heaven

Recommend hardware solution for multi rs485 channel?

Category: Computers and Hardware

- NWE

27 Dec 2025 03:07

Replied by NWE on topic DIY CNC Mill - Random Limit Switch Errors

DIY CNC Mill - Random Limit Switch Errors

Category: Milling Machines

- tar_san

- tar_san

27 Dec 2025 02:44 - 27 Dec 2025 02:56

Replied by tar_san on topic Ver 2.9.4 iso clean install Trouble when disabling EOE

Ver 2.9.4 iso clean install Trouble when disabling EOE

Category: EtherCAT

- NWE

27 Dec 2025 02:42

Replied by NWE on topic DIY CNC Mill - Random Limit Switch Errors

DIY CNC Mill - Random Limit Switch Errors

Category: Milling Machines

- sorokin_pro

27 Dec 2025 00:43

Replied by sorokin_pro on topic Mesa 6i25 not working?

Mesa 6i25 not working?

Category: Driver Boards

- PCW

27 Dec 2025 00:21

- NWE

27 Dec 2025 00:03

Replied by NWE on topic DIY CNC Mill - Random Limit Switch Errors

DIY CNC Mill - Random Limit Switch Errors

Category: Milling Machines

- tlightus

- tlightus

26 Dec 2025 23:59

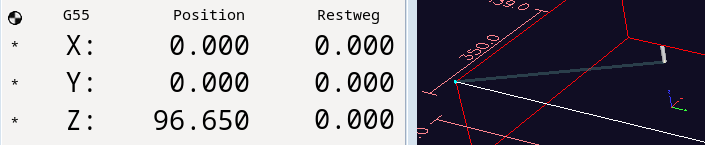

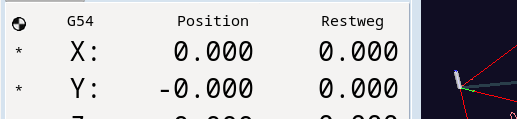

Replied by tlightus on topic calling subroutine from G54, G55, G56, but it acts weird

calling subroutine from G54, G55, G56, but it acts weird

Category: O Codes (subroutines) and NGCGUI

- sorokin_pro

26 Dec 2025 23:55

Replied by sorokin_pro on topic Mesa 6i25 not working?

Mesa 6i25 not working?

Category: Driver Boards

- MaHa

- MaHa

26 Dec 2025 23:32

Replied by MaHa on topic calling subroutine from G54, G55, G56, but it acts weird

calling subroutine from G54, G55, G56, but it acts weird

Category: O Codes (subroutines) and NGCGUI

- sorokin_pro

26 Dec 2025 23:27

Replied by sorokin_pro on topic Mesa 6i25 not working?

Mesa 6i25 not working?

Category: Driver Boards

Time to create page: 0.282 seconds