Search Results (Searched for: )

- Ul

- Ul

16 Dec 2025 15:04 - 16 Dec 2025 15:06

- feng

- feng

16 Dec 2025 13:13

- vibram

- vibram

16 Dec 2025 13:12

Replied by vibram on topic Ethercat compatible Encoder board tentative STM32F4 + LAN9252

Ethercat compatible Encoder board tentative STM32F4 + LAN9252

Category: EtherCAT

- Hakan

- Hakan

16 Dec 2025 12:24

Replied by Hakan on topic Ethercat compatible Encoder board tentative STM32F4 + LAN9252

Ethercat compatible Encoder board tentative STM32F4 + LAN9252

Category: EtherCAT

- unknown

- unknown

16 Dec 2025 11:43

Replied by unknown on topic Updating from LINUXCNC - 2.8.4-23, Mint 20.3 - gmoccapy lathe structure

Updating from LINUXCNC - 2.8.4-23, Mint 20.3 - gmoccapy lathe structure

Category: Gmoccapy

- unknown

- unknown

16 Dec 2025 11:39

Replied by unknown on topic Advantech PCM 9362 freze when opening latency-test

Advantech PCM 9362 freze when opening latency-test

Category: Computers and Hardware

- unknown

- unknown

16 Dec 2025 11:35

Replied by unknown on topic Advantech PCM 9362 freze when opening latency-test

Advantech PCM 9362 freze when opening latency-test

Category: Computers and Hardware

- sin-do-re

- sin-do-re

16 Dec 2025 11:29

- tommylight

16 Dec 2025 11:25

Replied by tommylight on topic Advantech PCM 9362 freze when opening latency-test

Advantech PCM 9362 freze when opening latency-test

Category: Computers and Hardware

- Masiwood123

16 Dec 2025 11:22

Replied by Masiwood123 on topic Physical buttons to 7i96s+7i77

Physical buttons to 7i96s+7i77

Category: HAL

- Muzzer

- Muzzer

16 Dec 2025 10:17

Replied by Muzzer on topic Updating from LINUXCNC - 2.8.4-23, Mint 20.3 - gmoccapy lathe structure

Updating from LINUXCNC - 2.8.4-23, Mint 20.3 - gmoccapy lathe structure

Category: Gmoccapy

- zoeper

- zoeper

16 Dec 2025 09:26

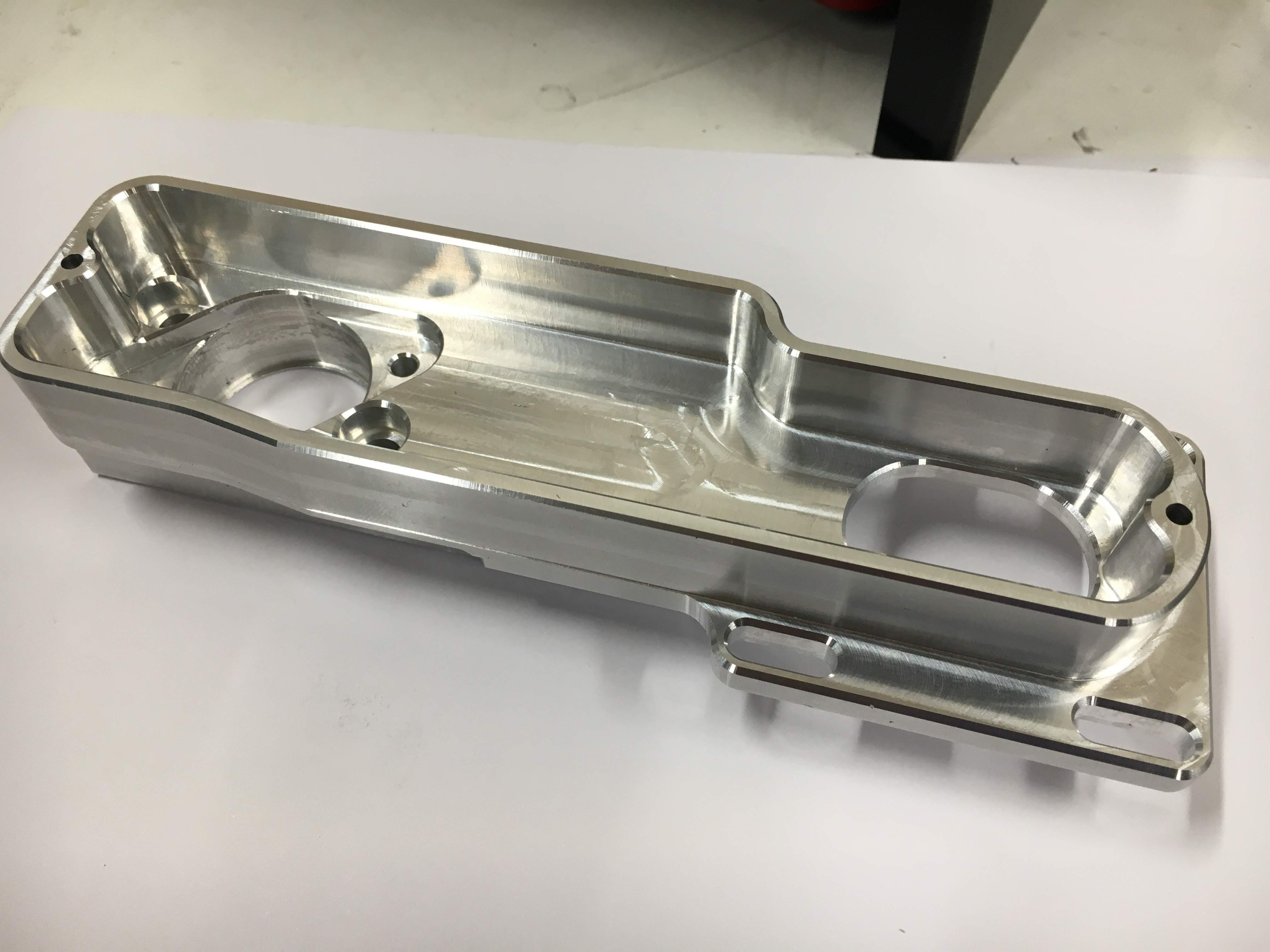

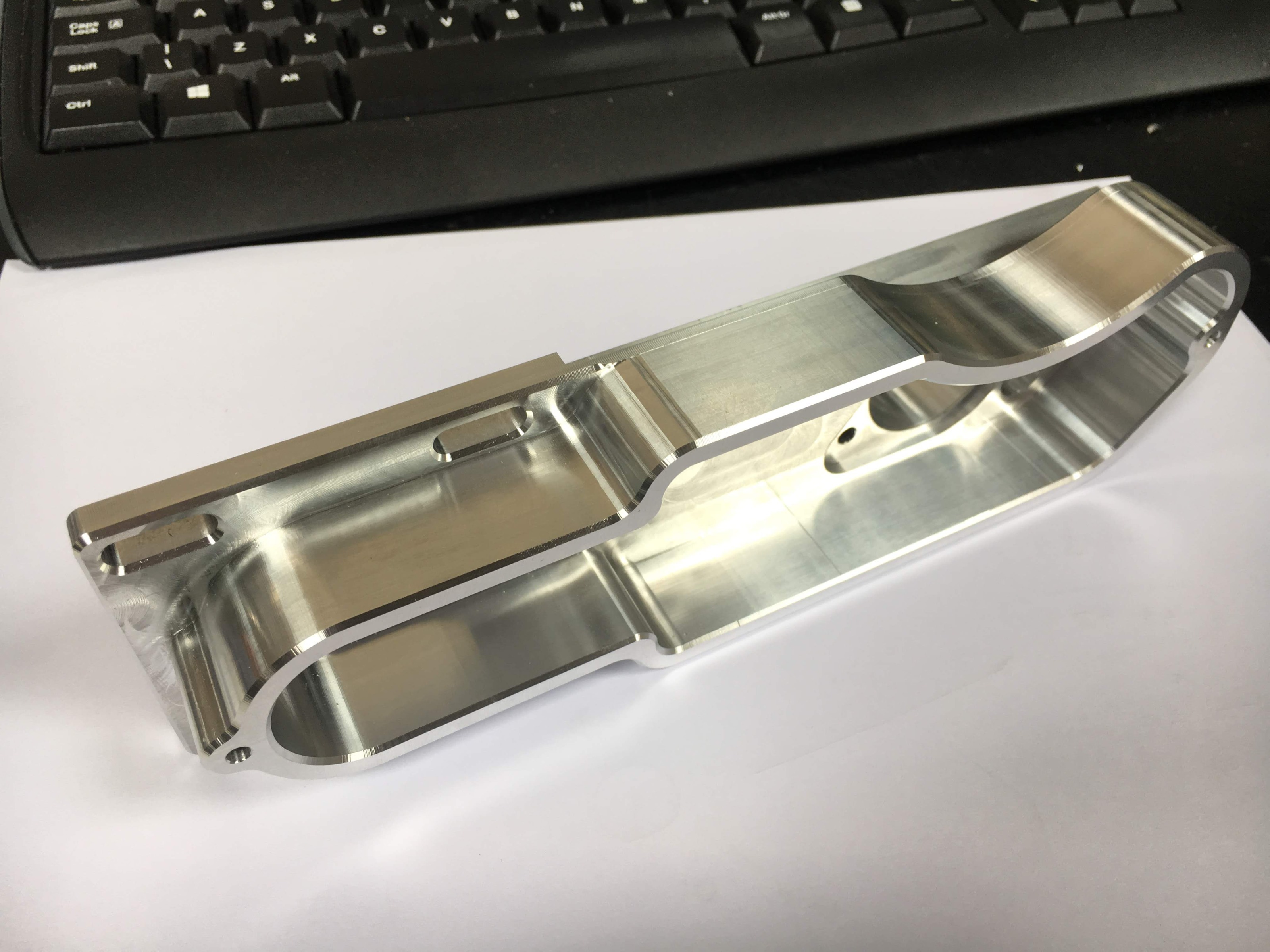

Replied by zoeper on topic Avon 3000 Mill retrofit

Avon 3000 Mill retrofit

Category: Milling Machines

- andrax

16 Dec 2025 08:38

- jaro_p

16 Dec 2025 08:27

Replied by jaro_p on topic Changes in configuration files generated in pncconfig for 7i76 to 7i78

Changes in configuration files generated in pncconfig for 7i76 to 7i78

Category: PnCConf Wizard

- gravedigger

- gravedigger

16 Dec 2025 06:37 - 16 Dec 2025 06:39

Replied by gravedigger on topic stepgen maxvel too big and SRO problem

stepgen maxvel too big and SRO problem

Category: Gmoccapy

Time to create page: 0.301 seconds