Search Results (Searched for: )

- tightmopedman9

- tightmopedman9

23 Sep 2025 18:14

Replied by tightmopedman9 on topic QtVCP Cannot Connect Message Dialog Box Hal Pin

QtVCP Cannot Connect Message Dialog Box Hal Pin

Category: Qtvcp

- JT

23 Sep 2025 16:18

Replied by JT on topic FlexGui touch - FSC-like myOwn tab from ext UI file

FlexGui touch - FSC-like myOwn tab from ext UI file

Category: Flex GUI

- JT

23 Sep 2025 16:13

Replied by JT on topic FlexGui touch - FSC-like myOwn tab from ext UI file

FlexGui touch - FSC-like myOwn tab from ext UI file

Category: Flex GUI

- JT

23 Sep 2025 15:38

Replied by JT on topic FlexGui touch - FSC-like myOwn tab from ext UI file

FlexGui touch - FSC-like myOwn tab from ext UI file

Category: Flex GUI

- ts

- ts

23 Sep 2025 14:55

Replied by ts on topic FlexGui touch - FSC-like myOwn tab from ext UI file

FlexGui touch - FSC-like myOwn tab from ext UI file

Category: Flex GUI

- spumco

- spumco

23 Sep 2025 14:26

Replied by spumco on topic G33.1 synchronized tapping problem

G33.1 synchronized tapping problem

Category: General LinuxCNC Questions

- ckuecker

- ckuecker

23 Sep 2025 14:03

- peterpan

- peterpan

23 Sep 2025 13:25

Replied by peterpan on topic Trouble with Cia402 drive configuration

Trouble with Cia402 drive configuration

Category: EtherCAT

- peterpan

- peterpan

23 Sep 2025 13:22

Replied by peterpan on topic Trouble with Cia402 drive configuration

Trouble with Cia402 drive configuration

Category: EtherCAT

- Aciera

23 Sep 2025 13:22 - 23 Sep 2025 13:31

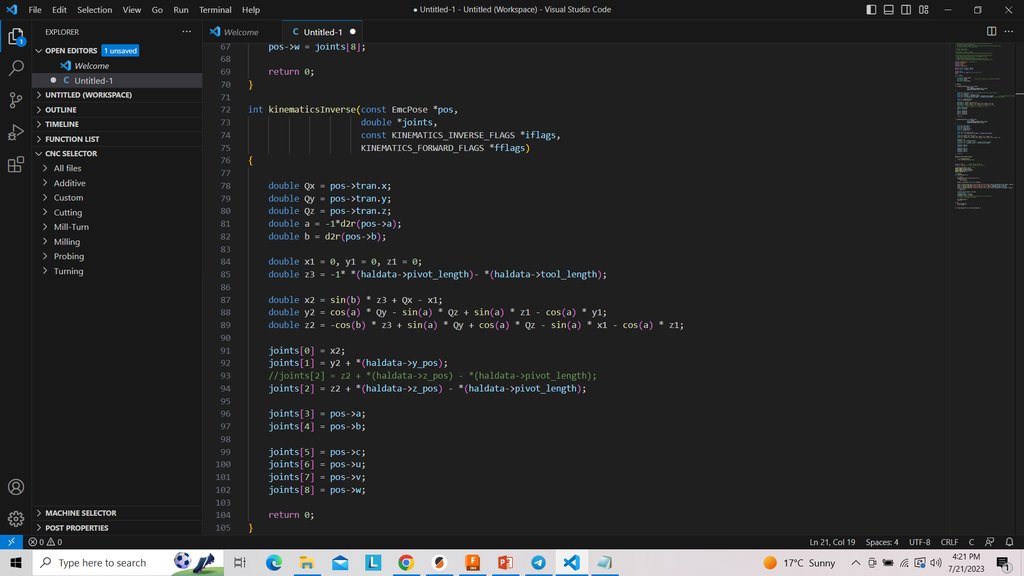

Replied by Aciera on topic Setting up kinematics for my Ballscrew articulated B-axis

Setting up kinematics for my Ballscrew articulated B-axis

Category: Basic Configuration

- RobotMatic

23 Sep 2025 12:06

Replied by RobotMatic on topic 7i76E Spindle configuration

7i76E Spindle configuration

Category: PnCConf Wizard

- alangibson

- alangibson

23 Sep 2025 11:38

Replied by alangibson on topic No underspeed with temporary material

No underspeed with temporary material

Category: Plasmac

- alangibson

- alangibson

23 Sep 2025 11:33

Replied by alangibson on topic MetalHeadCAM: dxf2gcode and Inkscape gcode plugin replacement

MetalHeadCAM: dxf2gcode and Inkscape gcode plugin replacement

Category: Plasmac

- cmorley

- cmorley

23 Sep 2025 11:18

Replied by cmorley on topic QtVCP Cannot Connect Message Dialog Box Hal Pin

QtVCP Cannot Connect Message Dialog Box Hal Pin

Category: Qtvcp

- Gautham

- Gautham

23 Sep 2025 04:53 - 23 Sep 2025 09:21

Replied by Gautham on topic Setting up kinematics for my Ballscrew articulated B-axis

Setting up kinematics for my Ballscrew articulated B-axis

Category: Basic Configuration

Time to create page: 0.227 seconds