Search Results (Searched for: )

- MaHa

- MaHa

21 Mar 2025 10:29

- UrKibin

- UrKibin

21 Mar 2025 10:11 - 21 Mar 2025 10:58

- UrKibin

- UrKibin

21 Mar 2025 10:10

- HansU

21 Mar 2025 10:04 - 21 Mar 2025 10:05

Replied by HansU on topic Keyboard Shortcuts in Gmoccapy

Keyboard Shortcuts in Gmoccapy

Category: Gmoccapy

- jazial

- jazial

21 Mar 2025 09:57

- HansU

21 Mar 2025 09:57

Replied by HansU on topic Keyboard Shortcuts in Gmoccapy

Keyboard Shortcuts in Gmoccapy

Category: Gmoccapy

- jazial

- jazial

21 Mar 2025 09:43

Replied by jazial on topic halui.spindle.0.override.direct-value

halui.spindle.0.override.direct-value

Category: Advanced Configuration

- Hakan

- Hakan

21 Mar 2025 07:08

Replied by Hakan on topic General Questions about using ethercat

General Questions about using ethercat

Category: EtherCAT

- RotarySMP

21 Mar 2025 05:54

- gm001

- gm001

21 Mar 2025 05:21

- SummerLotus

- SummerLotus

21 Mar 2025 02:41

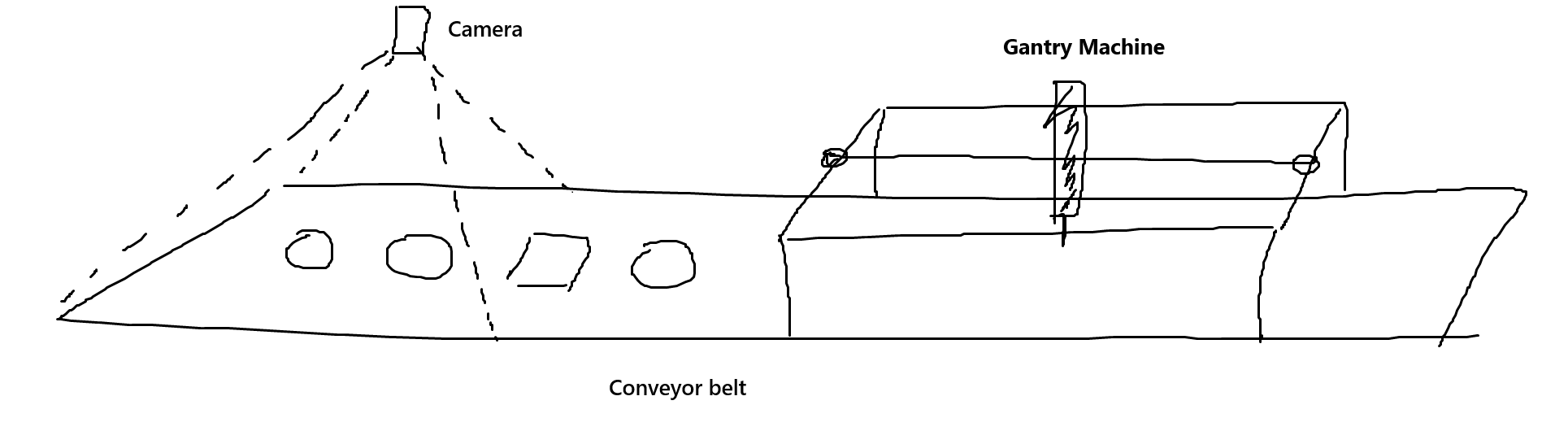

Regarding the question of following control on the assembly line was created by SummerLotus

Regarding the question of following control on the assembly line

Category: General LinuxCNC Questions

- Benb

21 Mar 2025 02:20

- wrhammer

- wrhammer

21 Mar 2025 01:58

Replied by wrhammer on topic Python commands lag time for remap

Python commands lag time for remap

Category: Advanced Configuration

- tommylight

21 Mar 2025 01:45

Replied by tommylight on topic 2.9.3 - Stuck in wrong state and stops

2.9.3 - Stuck in wrong state and stops

Category: Plasmac

- tommylight

21 Mar 2025 00:25

Replied by tommylight on topic Closed Loop DC Motor Remora EC500

Closed Loop DC Motor Remora EC500

Category: General LinuxCNC Questions

Time to create page: 0.462 seconds