Search Results (Searched for: )

- Simi02

- Simi02

16 Mar 2025 21:35

Replied by Simi02 on topic Problem with 6i25 + 7i77 PWM Pins

Problem with 6i25 + 7i77 PWM Pins

Category: PnCConf Wizard

- tommy

- tommy

16 Mar 2025 21:28 - 16 Mar 2025 21:29

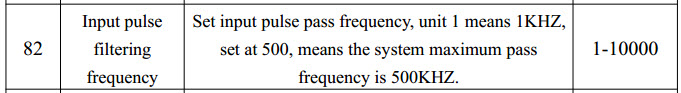

Replied by tommy on topic STEPLEN STEPSPACE time for Bergerda AC servo driver

STEPLEN STEPSPACE time for Bergerda AC servo driver

Category: General LinuxCNC Questions

- scda

16 Mar 2025 21:08

Replied by scda on topic caxis.comp with stepper motor / gear connection to spindle

caxis.comp with stepper motor / gear connection to spindle

Category: HAL

- PCW

16 Mar 2025 20:28

Replied by PCW on topic Mesa modbus and pktUart

Mesa modbus and pktUart

Category: Other User Interfaces

- Aciera

16 Mar 2025 19:11

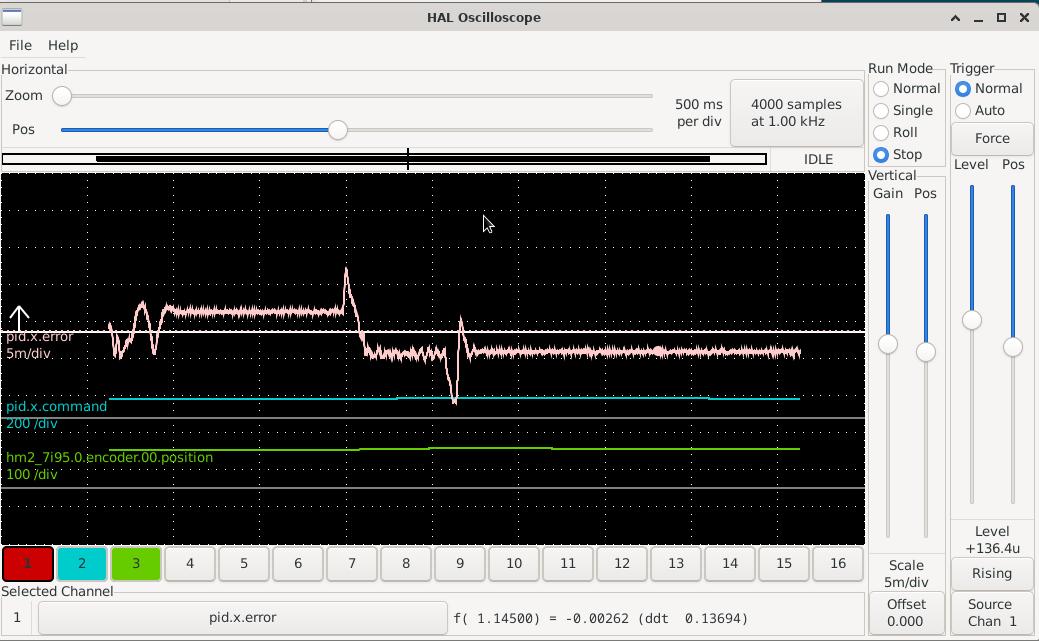

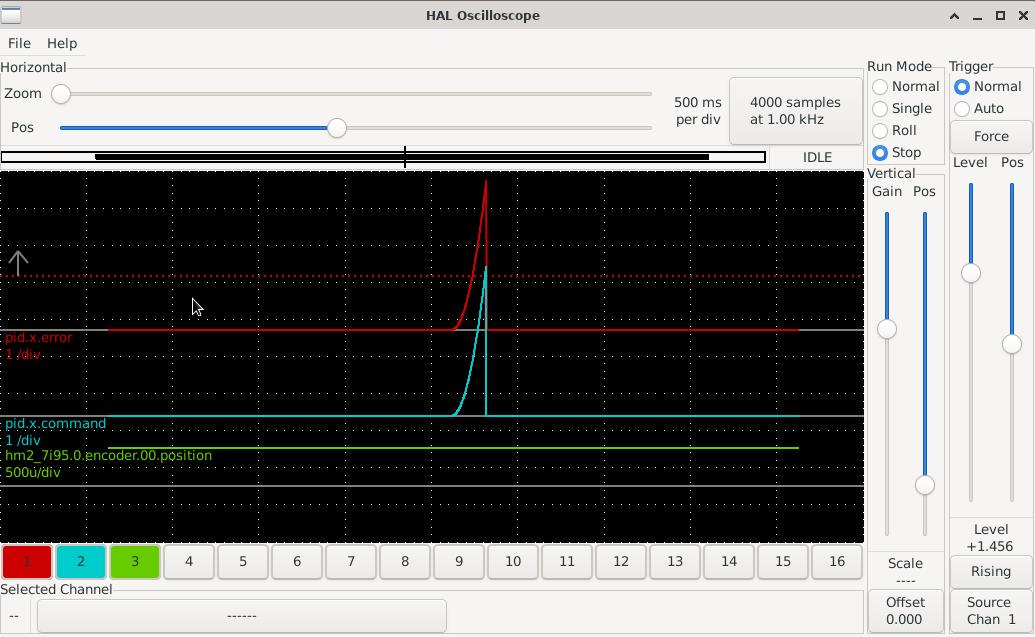

Replied by Aciera on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- vre

- vre

16 Mar 2025 19:11

Replied by vre on topic Mesa modbus and pktUart

Mesa modbus and pktUart

Category: Other User Interfaces

- spumco

- spumco

16 Mar 2025 18:30

Replied by spumco on topic caxis.comp with stepper motor / gear connection to spindle

caxis.comp with stepper motor / gear connection to spindle

Category: HAL

- PCW

16 Mar 2025 18:16

Replied by PCW on topic STEPLEN STEPSPACE time for Bergerda AC servo driver

STEPLEN STEPSPACE time for Bergerda AC servo driver

Category: General LinuxCNC Questions

- Wusel

- Wusel

16 Mar 2025 17:47

Replied by Wusel on topic Motor 0 Positionsfehler

Motor 0 Positionsfehler

Category: Advanced Configuration

- papagno-source

- papagno-source

16 Mar 2025 17:32 - 16 Mar 2025 17:41

Replied by papagno-source on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- Krulli_Fräser

- Krulli_Fräser

16 Mar 2025 17:01

Replied by Krulli_Fräser on topic Alcor 220CNC retrofit finished!

Alcor 220CNC retrofit finished!

Category: Milling Machines

- RotarySMP

16 Mar 2025 16:38

Replied by RotarySMP on topic Alcor 220CNC retrofit finished!

Alcor 220CNC retrofit finished!

Category: Milling Machines

- tommy

- tommy

16 Mar 2025 16:03

Replied by tommy on topic STEPLEN STEPSPACE time for Bergerda AC servo driver

STEPLEN STEPSPACE time for Bergerda AC servo driver

Category: General LinuxCNC Questions

- HansU

16 Mar 2025 15:44 - 16 Mar 2025 15:47

Replied by HansU on topic LCNC 2.10 - Ask for AUTOMATIC_G43

LCNC 2.10 - Ask for AUTOMATIC_G43

Category: Gmoccapy

- Krulli_Fräser

- Krulli_Fräser

16 Mar 2025 15:06 - 16 Mar 2025 15:07

Alcor 220CNC retrofit finished! was created by Krulli_Fräser

Alcor 220CNC retrofit finished!

Category: Milling Machines

Time to create page: 4.703 seconds