Search Results (Searched for: )

- PCW

15 Mar 2025 17:45

Replied by PCW on topic Motor 0 Positionsfehler

Motor 0 Positionsfehler

Category: Advanced Configuration

- tommy

- tommy

15 Mar 2025 17:32

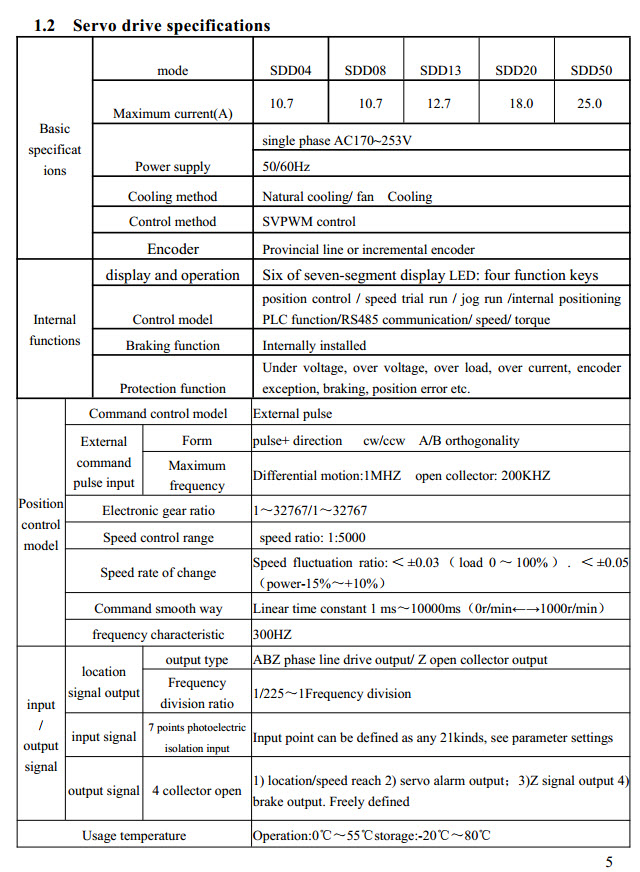

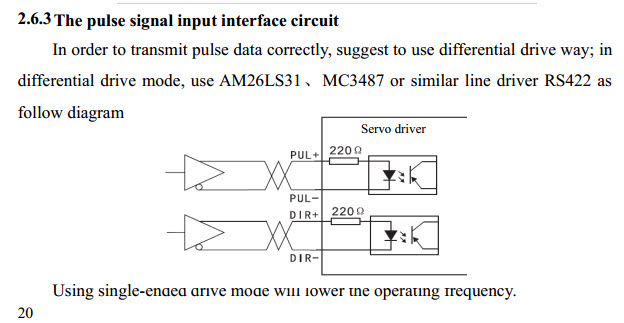

STEPLEN STEPSPACE time for Bergerda AC servo driver was created by tommy

STEPLEN STEPSPACE time for Bergerda AC servo driver

Category: General LinuxCNC Questions

- Wusel

- Wusel

15 Mar 2025 17:05

Replied by Wusel on topic Motor 0 Positionsfehler

Motor 0 Positionsfehler

Category: Advanced Configuration

- zz912

15 Mar 2025 17:03

Replied by zz912 on topic LCNC 2.10 - Ask for AUTOMATIC_G43

LCNC 2.10 - Ask for AUTOMATIC_G43

Category: Gmoccapy

- PCW

15 Mar 2025 15:45

- persei8

15 Mar 2025 15:38

- unknown

- unknown

15 Mar 2025 15:03

Replied by unknown on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- ihavenofish

- ihavenofish

15 Mar 2025 14:36

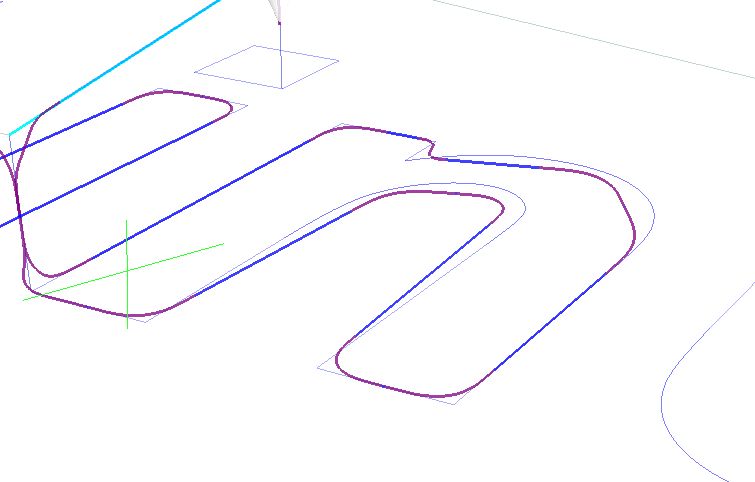

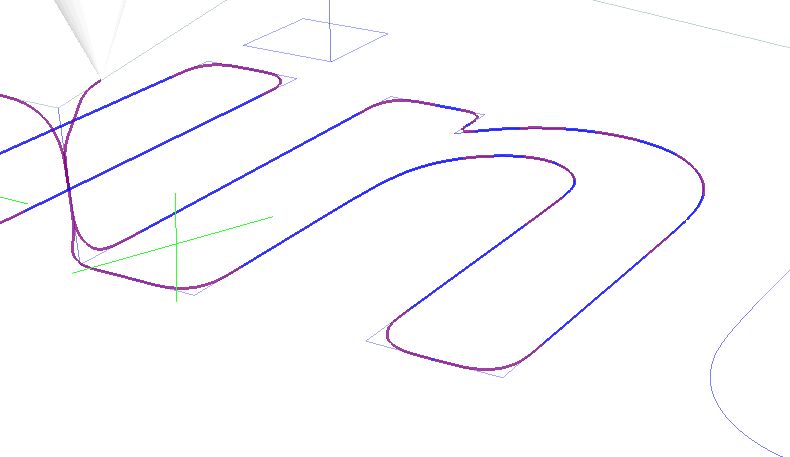

Replied by ihavenofish on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- JT

15 Mar 2025 13:44

Replied by JT on topic Funny message when reply to a topic

Funny message when reply to a topic

Category: Forum Questions

- U2fletch

- U2fletch

15 Mar 2025 13:20

Replied by U2fletch on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- tommylight

15 Mar 2025 13:10

Replied by tommylight on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- PCW

15 Mar 2025 12:31

Replied by PCW on topic Motor 0 Positionsfehler

Motor 0 Positionsfehler

Category: Advanced Configuration

- Grotius

15 Mar 2025 12:04

Replied by Grotius on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- NT4Boy

- NT4Boy

15 Mar 2025 10:14

Replied by NT4Boy on topic HURCO KMB-1 Control Update

HURCO KMB-1 Control Update

Category: Milling Machines

- unknown

- unknown

15 Mar 2025 10:11

Replied by unknown on topic SCATECH EV1616DN - Example config

SCATECH EV1616DN - Example config

Category: EtherCAT

Time to create page: 0.355 seconds