Search Results (Searched for: )

- HansU

15 Mar 2025 09:49

Replied by HansU on topic LCNC 2.10 - Ask for AUTOMATIC_G43

LCNC 2.10 - Ask for AUTOMATIC_G43

Category: Gmoccapy

- Wusel

- Wusel

15 Mar 2025 07:11

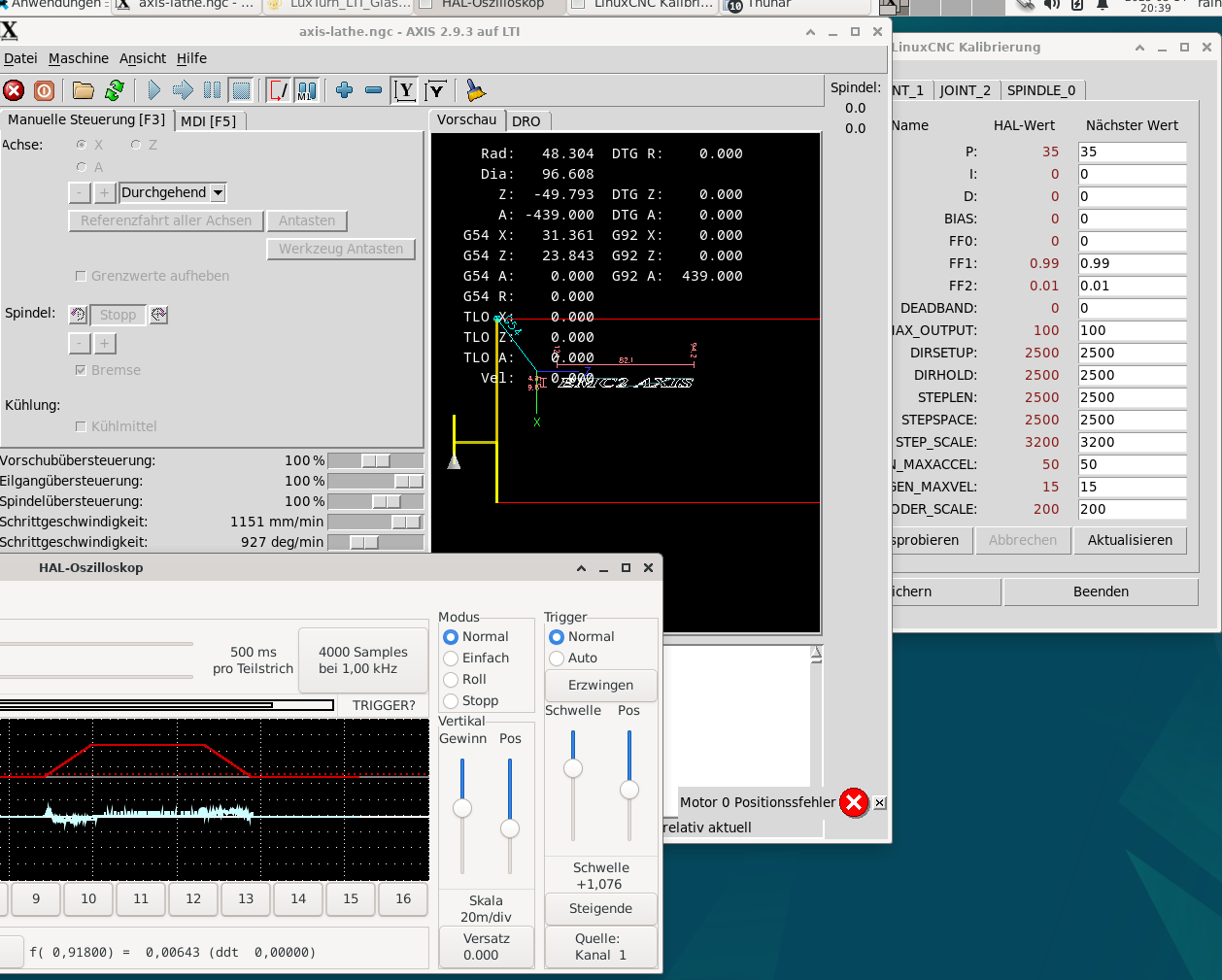

Motor 0 Positionsfehler was created by Wusel

Motor 0 Positionsfehler

Category: Advanced Configuration

- besriworld

- besriworld

15 Mar 2025 07:10

Replied by besriworld on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

- aikiaviator

- aikiaviator

15 Mar 2025 07:08

Replied by aikiaviator on topic Probe and Touchoff

Probe and Touchoff

Category: General LinuxCNC Questions

- darrylb123

- darrylb123

15 Mar 2025 05:49

Replied by darrylb123 on topic SCATECH EV1616DN - Example config

SCATECH EV1616DN - Example config

Category: EtherCAT

- unknown

- unknown

15 Mar 2025 05:37

Replied by unknown on topic SCATECH EV1616DN - Example config

SCATECH EV1616DN - Example config

Category: EtherCAT

- Hakan

- Hakan

15 Mar 2025 05:26

Replied by Hakan on topic SCATECH EV1616DN - Example config

SCATECH EV1616DN - Example config

Category: EtherCAT

- PCW

15 Mar 2025 05:10

Replied by PCW on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

- darrylb123

- darrylb123

15 Mar 2025 04:45

Replied by darrylb123 on topic SCATECH EV1616DN - Example config

SCATECH EV1616DN - Example config

Category: EtherCAT

- besriworld

- besriworld

15 Mar 2025 04:18 - 15 Mar 2025 04:47

Replied by besriworld on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

- unknown

- unknown

15 Mar 2025 04:18

Replied by unknown on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- U2fletch

- U2fletch

15 Mar 2025 04:01

Replied by U2fletch on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- U2fletch

- U2fletch

15 Mar 2025 03:54

Replied by U2fletch on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- PCW

15 Mar 2025 03:49

Replied by PCW on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

- besriworld

- besriworld

15 Mar 2025 03:03

Replied by besriworld on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

Time to create page: 0.269 seconds