Search Results (Searched for: )

- Aciera

04 Mar 2025 13:41

Replied by Aciera on topic Mitsubishi Meldas Control and Motors

Mitsubishi Meldas Control and Motors

Category: Milling Machines

- Ismacr63

- Ismacr63

04 Mar 2025 11:34

Replied by Ismacr63 on topic irregular machining

irregular machining

Category: General LinuxCNC Questions

- Grotius

04 Mar 2025 11:27

Replied by Grotius on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- besriworld

- besriworld

04 Mar 2025 11:26

Replied by besriworld on topic Mitsubishi Meldas Control and Motors

Mitsubishi Meldas Control and Motors

Category: Milling Machines

- timo

- timo

04 Mar 2025 11:09

Replied by timo on topic (not really) New machine geometry for plasma

(not really) New machine geometry for plasma

Category: Plasmac

- Hastrh2o

- Hastrh2o

04 Mar 2025 10:32 - 04 Mar 2025 10:34

(not really) New machine geometry for plasma was created by Hastrh2o

(not really) New machine geometry for plasma

Category: Plasmac

- Aciera

04 Mar 2025 09:40

- shaying526

- shaying526

04 Mar 2025 09:39

Issue with OP Entry Delay and Failures in LinuxCNC + EtherCAT System was created by shaying526

Issue with OP Entry Delay and Failures in LinuxCNC + EtherCAT System

Category: EtherCAT

- meister

- meister

04 Mar 2025 09:32

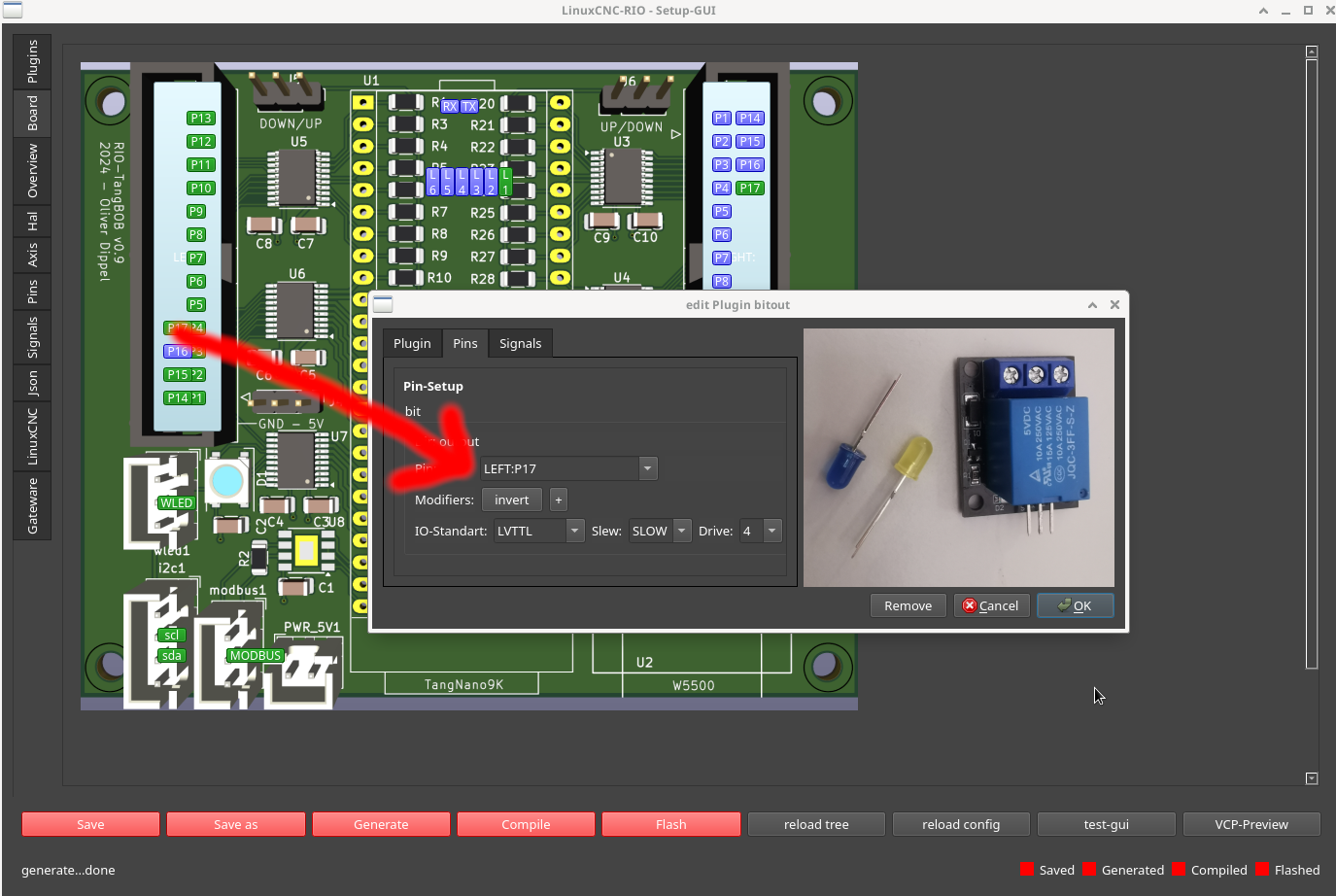

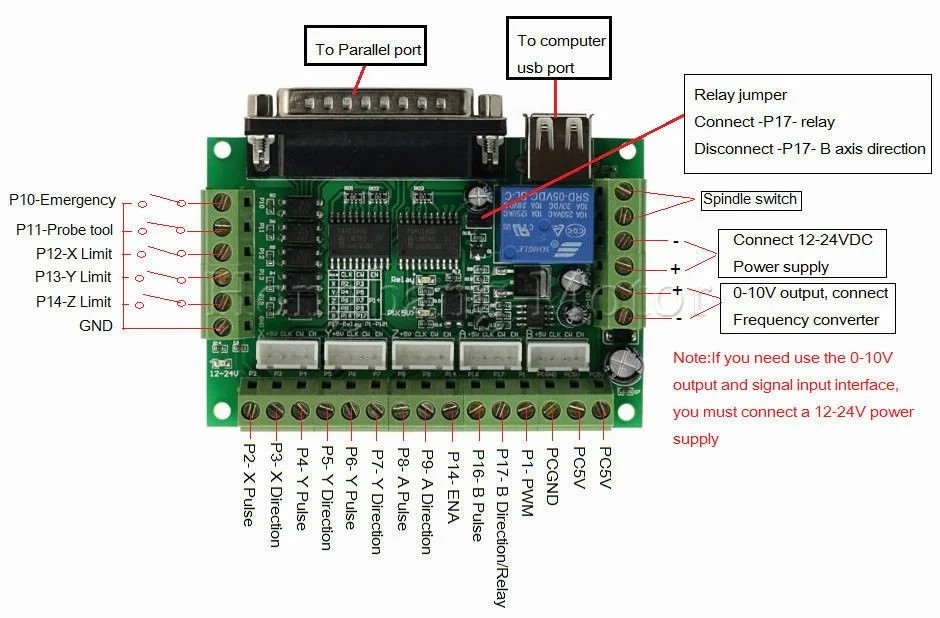

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- gmr

- gmr

04 Mar 2025 08:58

Mitsubishi Meldas Control and Motors was created by gmr

Mitsubishi Meldas Control and Motors

Category: Milling Machines

- kzali

- kzali

04 Mar 2025 08:51

- Mr. Mass

04 Mar 2025 07:46

- Piet

- Piet

04 Mar 2025 07:43

Replied by Piet on topic difference 7i76e and 7i76EU

difference 7i76e and 7i76EU

Category: Driver Boards

- stefan63

04 Mar 2025 07:12

Replied by stefan63 on topic Announcing Deckard: StreamDeck support for LinuxCNC

Announcing Deckard: StreamDeck support for LinuxCNC

Category: Show Your Stuff

- Hakan

- Hakan

04 Mar 2025 07:10

Replied by Hakan on topic Fusion 360 post processor file for Plamac

Fusion 360 post processor file for Plamac

Category: Plasmac

Time to create page: 0.538 seconds