Search Results (Searched for: THCAD)

05 Oct 2023 14:12

Replied by mariusl on topic Ohmic sensing with Mesa Thcad2

Ohmic sensing with Mesa Thcad2

Category: General LinuxCNC Questions

05 Oct 2023 13:46

Replied by PCW on topic Ohmic sensing with Mesa Thcad2

Ohmic sensing with Mesa Thcad2

Category: General LinuxCNC Questions

05 Oct 2023 12:48

Ohmic sensing with Mesa Thcad2 was created by mariusl

Ohmic sensing with Mesa Thcad2

Category: General LinuxCNC Questions

30 Sep 2023 13:26

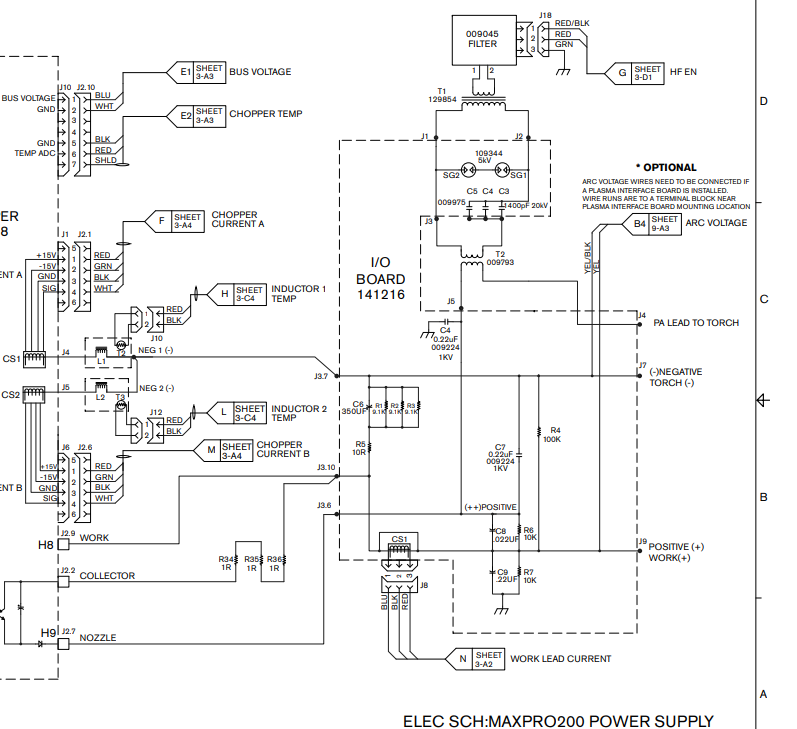

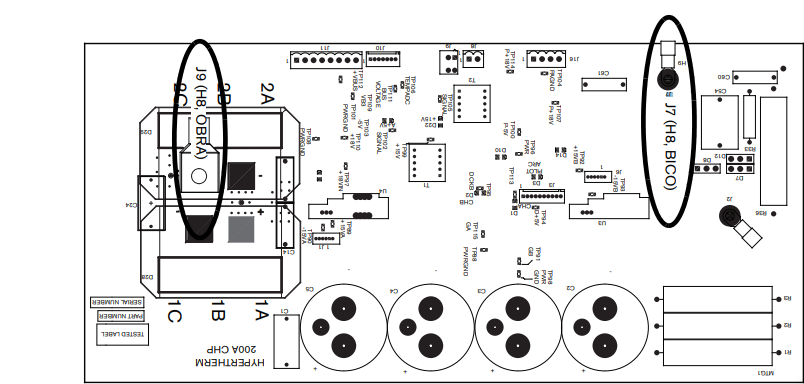

Replied by rodw on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

Hypertherm MAX PRO 200 CNC Connections - Quick Question

Category: Plasma & Laser

24 Sep 2023 23:55

Replied by tommylight on topic 7I84 Max Input Frequency

7I84 Max Input Frequency

Category: Driver Boards

24 Sep 2023 20:38

23 Sep 2023 15:40 - 23 Sep 2023 15:43

Replied by santy on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

Hypertherm MAX PRO 200 CNC Connections - Quick Question

Category: Plasma & Laser

19 Sep 2023 17:11

19 Sep 2023 10:11

19 Sep 2023 01:53

19 Sep 2023 00:16

18 Sep 2023 23:18

18 Sep 2023 21:44

Replied by rodw on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

Hypertherm MAX PRO 200 CNC Connections - Quick Question

Category: Plasma & Laser

18 Sep 2023 12:11

Replied by rodw on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

Hypertherm MAX PRO 200 CNC Connections - Quick Question

Category: Plasma & Laser

18 Sep 2023 11:34

Replied by RDA on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

Hypertherm MAX PRO 200 CNC Connections - Quick Question

Category: Plasma & Laser

Time to create page: 1.512 seconds