- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Configuring Plasmac - a complete THC/plasma config for any hardware

Configuring Plasmac - a complete THC/plasma config for any hardware

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

30 Apr 2019 10:33 #132337

by pl7i92

Replied by pl7i92 on topic Configuring Plasmac - a complete THC/plasma config for any hardware

it depends on how you work it is usabel and works great

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11661

- Thank you received: 3929

30 Apr 2019 10:41 - 30 Apr 2019 10:42 #132339

by rodw

Bevins, absolutely. John (Islander261) is using it in a production setting and says it is the best he's used. I've done enough cutting to know its stable. I think now the next (and probably last) feature is to integrate the LinuxCNC tool changer with the plasmac materials list. This would let the tool number retrieve the materials settings and set the kerf width (tool diameter) offset for both inside and outside cuts.

You may need to rewire ohmic sensing to the plasmac way. This requires a separate isolated power supply, a probe enable output and an ohmic sensor input (so the probe is disconnected at all times by some opto isolated relays unless probing and another relay is used to switch field power to the ohmic input.)

Replied by rodw on topic Configuring Plasmac - a complete THC/plasma config for any hardware

Is this usable for production?

Bevins, absolutely. John (Islander261) is using it in a production setting and says it is the best he's used. I've done enough cutting to know its stable. I think now the next (and probably last) feature is to integrate the LinuxCNC tool changer with the plasmac materials list. This would let the tool number retrieve the materials settings and set the kerf width (tool diameter) offset for both inside and outside cuts.

You may need to rewire ohmic sensing to the plasmac way. This requires a separate isolated power supply, a probe enable output and an ohmic sensor input (so the probe is disconnected at all times by some opto isolated relays unless probing and another relay is used to switch field power to the ohmic input.)

Last edit: 30 Apr 2019 10:42 by rodw.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

30 Apr 2019 14:05 #132351

by bevins

Is that absolutely necessary? Can do the same thing with sheetcam.

Replied by bevins on topic Configuring Plasmac - a complete THC/plasma config for any hardware

Is this usable for production?

Bevins, absolutely. John (Islander261) is using it in a production setting and says it is the best he's used. I've done enough cutting to know its stable. I think now the next (and probably last) feature is to integrate the LinuxCNC tool changer with the plasmac materials list. This would let the tool number retrieve the materials settings and set the kerf width (tool diameter) offset for both inside and outside cuts.

You may need to rewire ohmic sensing to the plasmac way. This requires a separate isolated power supply, a probe enable output and an ohmic sensor input (so the probe is disconnected at all times by some opto isolated relays unless probing and another relay is used to switch field power to the ohmic input.)

Is that absolutely necessary? Can do the same thing with sheetcam.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11661

- Thank you received: 3929

30 Apr 2019 20:07 #132367

by rodw

Replied by rodw on topic Configuring Plasmac - a complete THC/plasma config for any hardware

It comes down to which system will be the single point of truth. Linuxcnc or Sheetcam? WIth Plasmac, it will be LinuxCNC. Don't get me wrong. John and I both use sheetcam with plasmac but it is not mandatory.

Sheetcam will just need to send the ToolID via a Tn M6 command. All I can say is Plasmac is very different in its approach and is following the lead of gold standard plasma CNC systems, not what has been done in the past to work around the weaknesses of Mach3. Give it a try, you will be a convert!

Sheetcam will just need to send the ToolID via a Tn M6 command. All I can say is Plasmac is very different in its approach and is following the lead of gold standard plasma CNC systems, not what has been done in the past to work around the weaknesses of Mach3. Give it a try, you will be a convert!

Please Log in or Create an account to join the conversation.

- JTknives

-

- Offline

- Elite Member

-

Less

More

- Posts: 243

- Thank you received: 32

30 Apr 2019 20:33 #132370

by JTknives

Replied by JTknives on topic Configuring Plasmac - a complete THC/plasma config for any hardware

sorry if this is a dumb question but how does one go about defining inputs and outputs. How is each pin labeled and is there a list of them? I searched but did not seam to find anything to describe how to do it but that could be because i'm not sure what to search for.

jtknives@plasma:~$ . plasmac/scripts/rip-environment

jtknives@plasma:~$ linuxcnc

LINUXCNC - 2.8.0~pre1

Machine configuration directory is '/home/jtknives/linuxcnc/configs/plasmac'

Machine configuration file is 'mymachine.ini'

check_config: (trivkins kinematics) WARNING:

Unspecified [JOINT_0]MAX_VELOCITY, default used: 1.0

Unspecified [JOINT_0]MAX_ACCELERATION, default used: 1.0

Unspecified [JOINT_1]MAX_VELOCITY, default used: 1.0

Unspecified [JOINT_1]MAX_ACCELERATION, default used: 1.0

Unspecified [JOINT_2]MAX_VELOCITY, default used: 1.0

Unspecified [JOINT_2]MAX_ACCELERATION, default used: 1.0

Starting LinuxCNC...

twopass:invoked with <> options

twopass:found ./machine.hal

twopass:found ./plasmac.hal

Note: Using POSIX realtime

hm2: loading Mesa HostMot2 driver version 0.15

hm2_eth: loading Mesa AnyIO HostMot2 ethernet driver version 0.2

hm2_eth: 10.10.10.10: Hardware address: 00:60:1b:10:80:32

hm2_eth: discovered 7I76E-16

hm2/hm2_7i76e.0: Smart Serial Firmware Version 43

Board hm2_7i76e.0.7i76.0.0 Hardware Mode 0 = standard

Board hm2_7i76e.0.7i76.0.0 Software Mode 0 = io_spin

Board hm2_7i76e.0.7i76.0.0 Software Mode 1 = io_ana_spin

Board hm2_7i76e.0.7i76.0.0 Software Mode 2 = io_enc_ana_spin_fv

hm2/hm2_7i76e.0: 51 I/O Pins used:

hm2/hm2_7i76e.0: IO Pin 000 (P1-01): StepGen #0, pin Direction (Output)

hm2/hm2_7i76e.0: IO Pin 001 (P1-14): StepGen #0, pin Step (Output)

hm2/hm2_7i76e.0: IO Pin 002 (P1-02): StepGen #1, pin Direction (Output)

hm2/hm2_7i76e.0: IO Pin 003 (P1-15): StepGen #1, pin Step (Output)

hm2/hm2_7i76e.0: IO Pin 004 (P1-03): StepGen #2, pin Direction (Output)

hm2/hm2_7i76e.0: IO Pin 005 (P1-16): StepGen #2, pin Step (Output)

hm2/hm2_7i76e.0: IO Pin 006 (P1-04): IOPort

hm2/hm2_7i76e.0: IO Pin 007 (P1-17): IOPort

hm2/hm2_7i76e.0: IO Pin 008 (P1-05): IOPort

hm2/hm2_7i76e.0: IO Pin 009 (P1-06): IOPort

hm2/hm2_7i76e.0: IO Pin 010 (P1-07): Smart Serial Interface #0, pin TxData0 (Output)

hm2/hm2_7i76e.0: IO Pin 011 (P1-08): Smart Serial Interface #0, pin RxData0 (Input)

hm2/hm2_7i76e.0: IO Pin 012 (P1-09): IOPort

hm2/hm2_7i76e.0: IO Pin 013 (P1-10): IOPort

hm2/hm2_7i76e.0: IO Pin 014 (P1-11): Encoder #0, pin Index (Input)

hm2/hm2_7i76e.0: IO Pin 015 (P1-12): Encoder #0, pin B (Input)

hm2/hm2_7i76e.0: IO Pin 016 (P1-13): Encoder #0, pin A (Input)

hm2/hm2_7i76e.0: IO Pin 017 (P2-01): IOPort

hm2/hm2_7i76e.0: IO Pin 018 (P2-14): IOPort

hm2/hm2_7i76e.0: IO Pin 019 (P2-02): IOPort

hm2/hm2_7i76e.0: IO Pin 020 (P2-15): IOPort

hm2/hm2_7i76e.0: IO Pin 021 (P2-03): IOPort

hm2/hm2_7i76e.0: IO Pin 022 (P2-16): IOPort

hm2/hm2_7i76e.0: IO Pin 023 (P2-04): IOPort

hm2/hm2_7i76e.0: IO Pin 024 (P2-17): IOPort

hm2/hm2_7i76e.0: IO Pin 025 (P2-05): IOPort

hm2/hm2_7i76e.0: IO Pin 026 (P2-06): IOPort

hm2/hm2_7i76e.0: IO Pin 027 (P2-07): IOPort

hm2/hm2_7i76e.0: IO Pin 028 (P2-08): IOPort

hm2/hm2_7i76e.0: IO Pin 029 (P2-09): IOPort

hm2/hm2_7i76e.0: IO Pin 030 (P2-10): IOPort

hm2/hm2_7i76e.0: IO Pin 031 (P2-11): IOPort

hm2/hm2_7i76e.0: IO Pin 032 (P2-12): IOPort

hm2/hm2_7i76e.0: IO Pin 033 (P2-13): IOPort

hm2/hm2_7i76e.0: IO Pin 034 (P3-01): IOPort

hm2/hm2_7i76e.0: IO Pin 035 (P3-14): IOPort

hm2/hm2_7i76e.0: IO Pin 036 (P3-02): IOPort

hm2/hm2_7i76e.0: IO Pin 037 (P3-15): IOPort

hm2/hm2_7i76e.0: IO Pin 038 (P3-03): IOPort

hm2/hm2_7i76e.0: IO Pin 039 (P3-16): IOPort

hm2/hm2_7i76e.0: IO Pin 040 (P3-04): IOPort

hm2/hm2_7i76e.0: IO Pin 041 (P3-17): IOPort

hm2/hm2_7i76e.0: IO Pin 042 (P3-05): IOPort

hm2/hm2_7i76e.0: IO Pin 043 (P3-06): IOPort

hm2/hm2_7i76e.0: IO Pin 044 (P3-07): IOPort

hm2/hm2_7i76e.0: IO Pin 045 (P3-08): IOPort

hm2/hm2_7i76e.0: IO Pin 046 (P3-09): IOPort

hm2/hm2_7i76e.0: IO Pin 047 (P3-10): IOPort

hm2/hm2_7i76e.0: IO Pin 048 (P3-11): IOPort

hm2/hm2_7i76e.0: IO Pin 049 (P3-12): IOPort

hm2/hm2_7i76e.0: IO Pin 050 (P3-13): IOPort

hm2/hm2_7i76e.0: registered

twopass: Error in file ./machine.hal:

Pin 'hm2_7i76e.0.7i76.0.0.output-??' does not exist

twopass: Error in file ./plasmac.hal:

Pin 'joint.3.pos-fb' does not exist

Shutting down and cleaning up LinuxCNC...

hm2_eth: HostMot2 ethernet driver unloaded

hm2: unloading

Note: Using POSIX realtime

LinuxCNC terminated with an error. You can find more information in the log:

/home/jtknives/linuxcnc_debug.txt

and

/home/jtknives/linuxcnc_print.txt

as well as in the output of the shell command 'dmesg' and in the terminal

jtknives@plasma:~$ Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11661

- Thank you received: 3929

30 Apr 2019 20:53 #132374

by rodw

Replied by rodw on topic Configuring Plasmac - a complete THC/plasma config for any hardware

Easiest way is to click on the halshow button in plasmac and browse to your hearts content. Find the 7i76e and click down a few levels and all will be revealed. Also note how you can click on the watch tab and then click on a pin in the tree and watch it turn on and off. I use this extensively when setting up a new feature.

The other way while you have plasmac open is to open a new terminal window, set the rip-environment then type halcmd show pin

You could save the output for further reference if you typed halcmd show pin > mypins.txt But I always just use halshow which is a standard tool that comes with Linuxcnc.

The other way while you have plasmac open is to open a new terminal window, set the rip-environment then type halcmd show pin

You could save the output for further reference if you typed halcmd show pin > mypins.txt But I always just use halshow which is a standard tool that comes with Linuxcnc.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11661

- Thank you received: 3929

30 Apr 2019 21:02 - 30 Apr 2019 21:03 #132375

by rodw

Replied by rodw on topic Configuring Plasmac - a complete THC/plasma config for any hardware

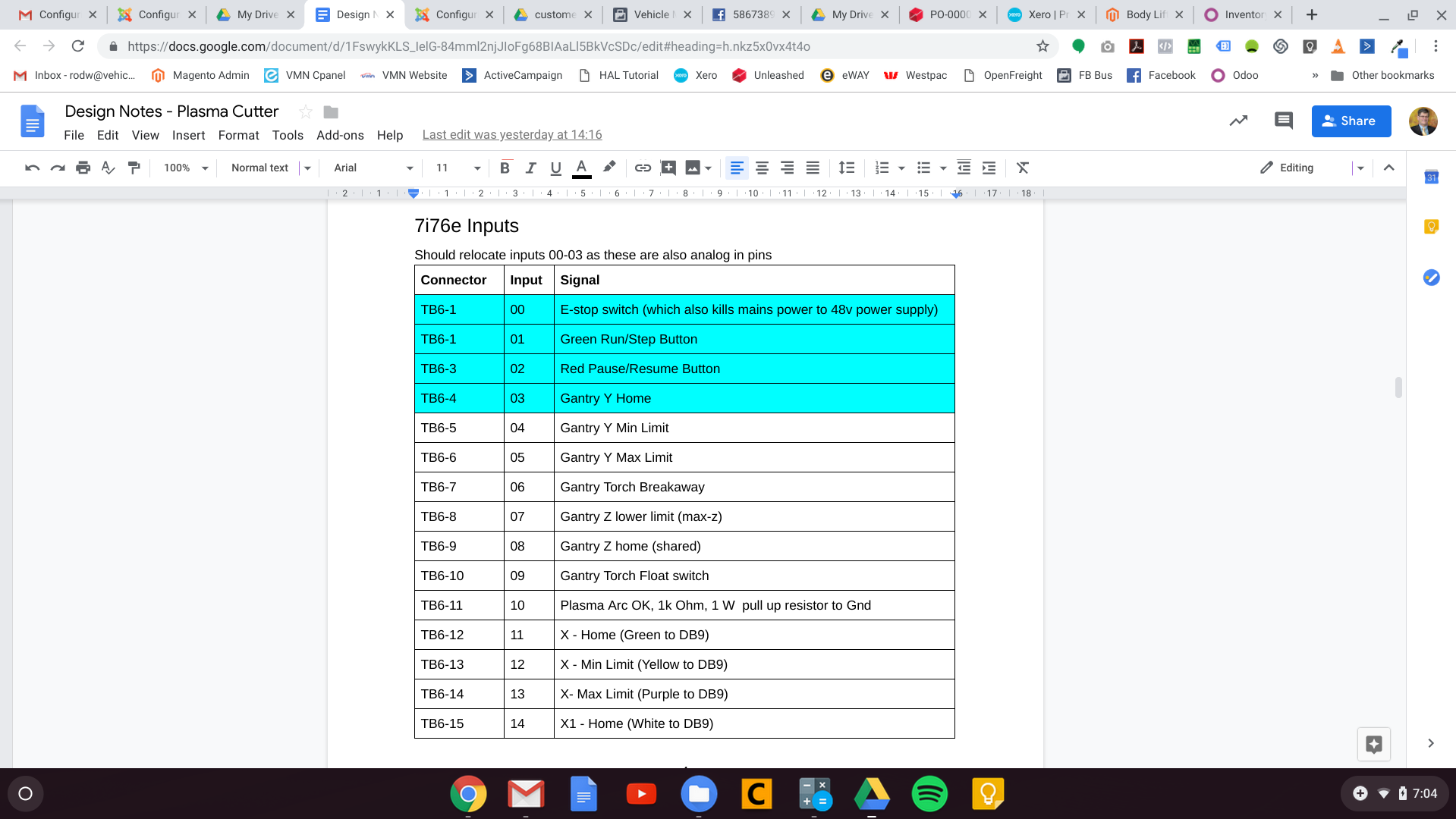

Just looked at your output. You just need to replace the question marks in the hal file John wrote for you with the real pin number. Either use Halshow or use the 7i76e manual. The manual is a bit confusing as the hardware pins are numbered from 1, but the output pins start at INPUT0.

So if you connect a wire to TB6 Pin 5, it will be INPUT4. In halshow, it will be hm2_7i76e.0.7i76.0.0.input-04. You can always check a pin by jumpering field power to it and watching it change state in halshow.

So if you connect a wire to TB6 Pin 5, it will be INPUT4. In halshow, it will be hm2_7i76e.0.7i76.0.0.input-04. You can always check a pin by jumpering field power to it and watching it change state in halshow.

Last edit: 30 Apr 2019 21:03 by rodw.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11661

- Thank you received: 3929

30 Apr 2019 21:06 #132376

by rodw

Replied by rodw on topic Configuring Plasmac - a complete THC/plasma config for any hardware

Attachments:

Please Log in or Create an account to join the conversation.

- JTknives

-

- Offline

- Elite Member

-

Less

More

- Posts: 243

- Thank you received: 32

30 Apr 2019 21:50 #132379

by JTknives

Replied by JTknives on topic Configuring Plasmac - a complete THC/plasma config for any hardware

But how does it know your talking about TB6 and not any of the other TB# inputs/outputs.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11661

- Thank you received: 3929

30 Apr 2019 22:09 #132380

by rodw

Replied by rodw on topic Configuring Plasmac - a complete THC/plasma config for any hardware

Because page 11 of the 7i76e Manual says that Input 4 is on TB6 pin 5.But how does it know your talking about TB6 and not any of the other TB# inputs/outputs.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

- Hardware & Machines

- CNC Machines

- Plasma & Laser

- Configuring Plasmac - a complete THC/plasma config for any hardware

Time to create page: 0.136 seconds