just another plasma build and then some :)

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

23 Apr 2020 22:09 #165314

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

and i very much agree about the internet being a mine field of bad information with out a doubt. but it passes the time on the night shift to make the night go faster

it does have to do with the coils in the winding's but has a lot of logic in the background as a result. so why you would go this route and not just use servo's to begin with is beyond me? especially with the price point on the cheaper servo systems.

looks like it will stay as is for a bit and later maybe upgrade to a servo system.

it does have to do with the coils in the winding's but has a lot of logic in the background as a result. so why you would go this route and not just use servo's to begin with is beyond me? especially with the price point on the cheaper servo systems.

looks like it will stay as is for a bit and later maybe upgrade to a servo system.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11563

- Thank you received: 3882

23 Apr 2020 23:18 #165321

by rodw

Replied by rodw on topic just another plasma build and then some :)

There is nothing really wrong with a stepper system if its properly set up. Because your ball screws are the limiting factor with max velocity, you could save your money and apply it elsewhere... In your spare time come up with a moving nut modification before you spend on servos....

The following user(s) said Thank You: tommylight, thefabricator03

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21068

- Thank you received: 7188

23 Apr 2020 23:34 #165324

by tommylight

Replied by tommylight on topic just another plasma build and then some :)

Yeah, moving nuts are NUTS ! I did a test a while back on a 2505 ball screw and i could move it at 68m/m without load and with only 24V supply to the drive! But adjusting axial bearings is quite the challenge. Thought of trying angled roller bearings, but got sidetracked. And there is the issue of bolting down the sides of the screw so it does not fly off at those speeds.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

24 Apr 2020 00:37 #165330

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

i would imagine ball nuts have limits on speeds like bearings do. some ball nuts have a preferred mounting so the ball can circulate properly too. so some care needs to be taken with with the moving nuts in a design.

and back to the original concern i have you still have backlash error and lead screw error. so if you want to remove those you can do it with screw mapping and backlash comp but those add a correction lag time to the system. and not to mention it's just and end position correction. this is what got me on the linear encoder band wagon to begin with. you bypass the error by getting feedback on the actual position. that's the attractive part of linear encoders for feed back.

and back to the original concern i have you still have backlash error and lead screw error. so if you want to remove those you can do it with screw mapping and backlash comp but those add a correction lag time to the system. and not to mention it's just and end position correction. this is what got me on the linear encoder band wagon to begin with. you bypass the error by getting feedback on the actual position. that's the attractive part of linear encoders for feed back.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

24 Apr 2020 01:04 #165334

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

one other aspect i have to deal with is a heavy gantry. so moving at rotating nut speeds will cause some issues. the cross beam axis of my machine has some good acceleration and when it is cranked up it will make things move in ways you don't want to see things move.

strictly plasma with a super light gantry will run circles around what i have in acceleration and speed. when you have the extra weight it needs extra time to accelerate and slow back down.

i do think once i finish the E.G on the table i can push the acceleration up because the machine base will have a lot more mass to it though. i might get the mold built this weekend and start do that part real soon.

strictly plasma with a super light gantry will run circles around what i have in acceleration and speed. when you have the extra weight it needs extra time to accelerate and slow back down.

i do think once i finish the E.G on the table i can push the acceleration up because the machine base will have a lot more mass to it though. i might get the mold built this weekend and start do that part real soon.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

24 Apr 2020 02:09 #165341

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

i was thinking DYN4 drives were only 240V AC but they can run on 120V AC i already have these. i was trying to keep things limited to 120V just because i have to much other stuff in the shop  i guess if i really wanted things to work better i could use them instead of the steppers. im pretty sure the speeds are reduced quite a bit when you run them on 120V but with the 750w motors i could probably get more than enough out of them and get what i want. i will have to look at that tonight while i am at work and refresh myself on the set up of those

i guess if i really wanted things to work better i could use them instead of the steppers. im pretty sure the speeds are reduced quite a bit when you run them on 120V but with the 750w motors i could probably get more than enough out of them and get what i want. i will have to look at that tonight while i am at work and refresh myself on the set up of those

The following user(s) said Thank You: tommylight, thefabricator03

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

26 Apr 2020 20:18 #165689

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

this molding of the frame in E.G. has been a lot of work. i thought i had just about everything cut out but when i started putting things together i quickly found out i was missing some pieces  way to many pieces to keep track of

way to many pieces to keep track of  and it went together in CAD a lot easier than in reality. if i had some extra hand around to help it would have been a lot easier

and it went together in CAD a lot easier than in reality. if i had some extra hand around to help it would have been a lot easier  hopefully i can pick away here and there this week coming and get things ready to cast over next weekend?

hopefully i can pick away here and there this week coming and get things ready to cast over next weekend?

Attachments:

The following user(s) said Thank You: tommylight, thefabricator03

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21068

- Thank you received: 7188

26 Apr 2020 20:23 #165691

by tommylight

Replied by tommylight on topic just another plasma build and then some :)

Nice.

Think of us cheering you !

Think of us cheering you !

The following user(s) said Thank You: machinedude

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

26 Apr 2020 20:35 #165695

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

should make for a nice machine base and sub table. in the beginning i thought i could tear the table down if i had to move the machine but that plan went out the window i while ago  once i seen the frame work on the top i was like E.G. would work so well there the way things turned out because of how it's a bunch of interlocking cells. then as some time went by i figured if i could figure out a way to tie the table top to the frame that would be even better so this is where i landed

once i seen the frame work on the top i was like E.G. would work so well there the way things turned out because of how it's a bunch of interlocking cells. then as some time went by i figured if i could figure out a way to tie the table top to the frame that would be even better so this is where i landed  hopefully it's not flat on my face

hopefully it's not flat on my face

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

03 May 2020 02:07 #166457

by machinedude

Replied by machinedude on topic just another plasma build and then some :)

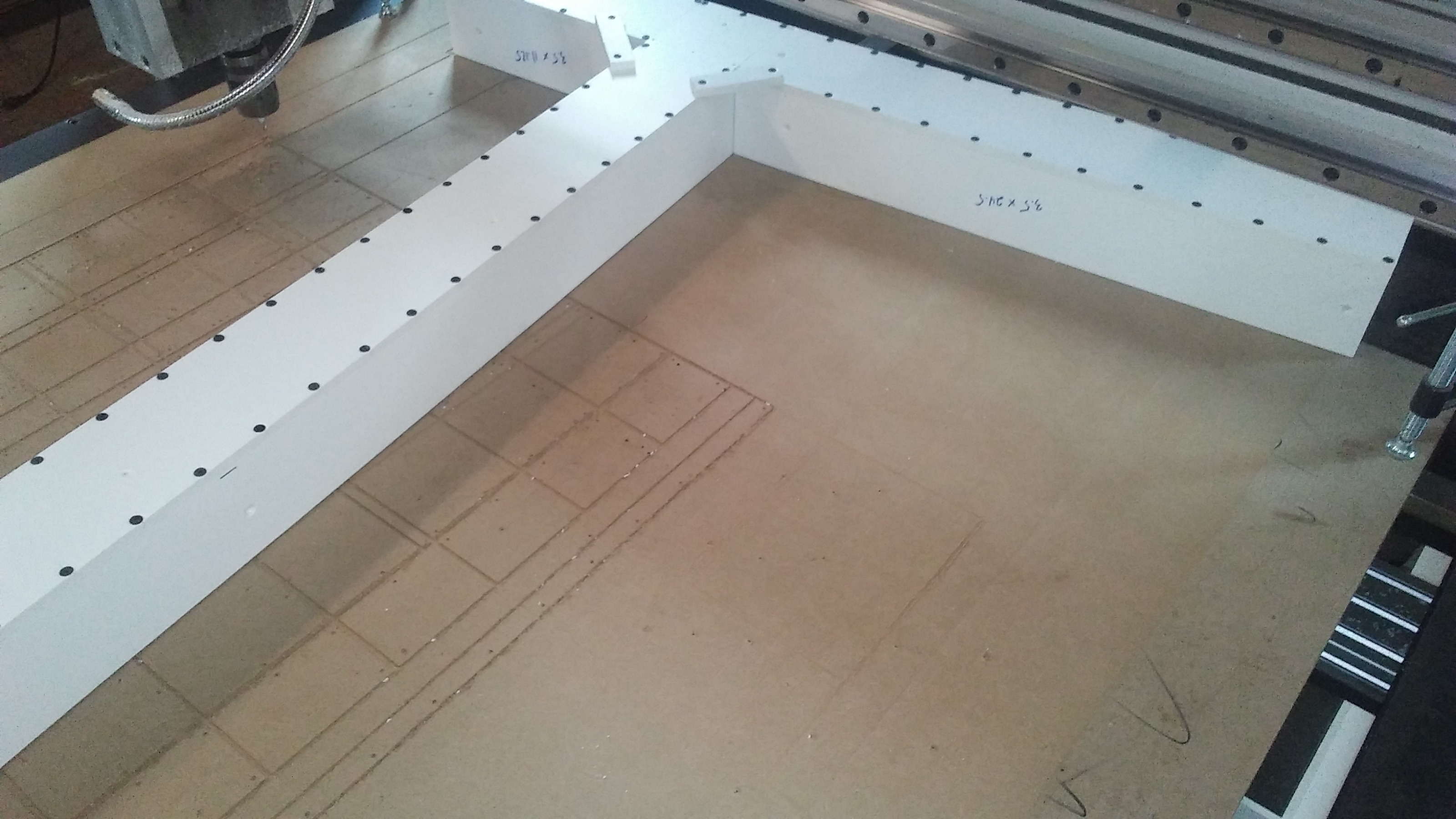

I think i have A.D.D.  i was thinking i would be casting by now but just finished the mold and it's to late to get into anything now. T.he Table top ended up getting more involved then i expected and took me all day to get sorted out. i was working til 2:00 am last night but did not get anywhere because i was to busy going over everything 2 and 3 times.

i was thinking i would be casting by now but just finished the mold and it's to late to get into anything now. T.he Table top ended up getting more involved then i expected and took me all day to get sorted out. i was working til 2:00 am last night but did not get anywhere because i was to busy going over everything 2 and 3 times.

now that it's in front of me this thing is going to take a while to cast. the amount of mixing and working into the mold i am not looking forward too working the air out of the mix is probably not going to be much better

working the air out of the mix is probably not going to be much better

for the most part i kept things open around the ball screw just so it would not be a nightmare to work on down the road if something should happen. had to create some clearance down the center 3/4 deep for mechanical stuff to clear. i used a hard board for most of the table trying to save some money the plastic is about $80 a sheet compared to $9 a sheet for the hard board. the hard board will need some mold release to be safe but the plastic probably won't the the extra help for releasing from the from the frame.

now that it's in front of me this thing is going to take a while to cast. the amount of mixing and working into the mold i am not looking forward too

for the most part i kept things open around the ball screw just so it would not be a nightmare to work on down the road if something should happen. had to create some clearance down the center 3/4 deep for mechanical stuff to clear. i used a hard board for most of the table trying to save some money the plastic is about $80 a sheet compared to $9 a sheet for the hard board. the hard board will need some mold release to be safe but the plastic probably won't the the extra help for releasing from the from the frame.

Attachments:

The following user(s) said Thank You: tommylight, thefabricator03

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 3.131 seconds