3.5X1.5 Meters cnc plasma cutter

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

27 Oct 2019 19:10 - 08 Feb 2020 20:29 #148916

by tommylight

3.5X1.5 Meters cnc plasma cutter was created by tommylight

Last few days been working on this :

The machine dimensions are 4.2X1.75 meters, cut area will end up to 3.6X1.35 meters, so big enough.

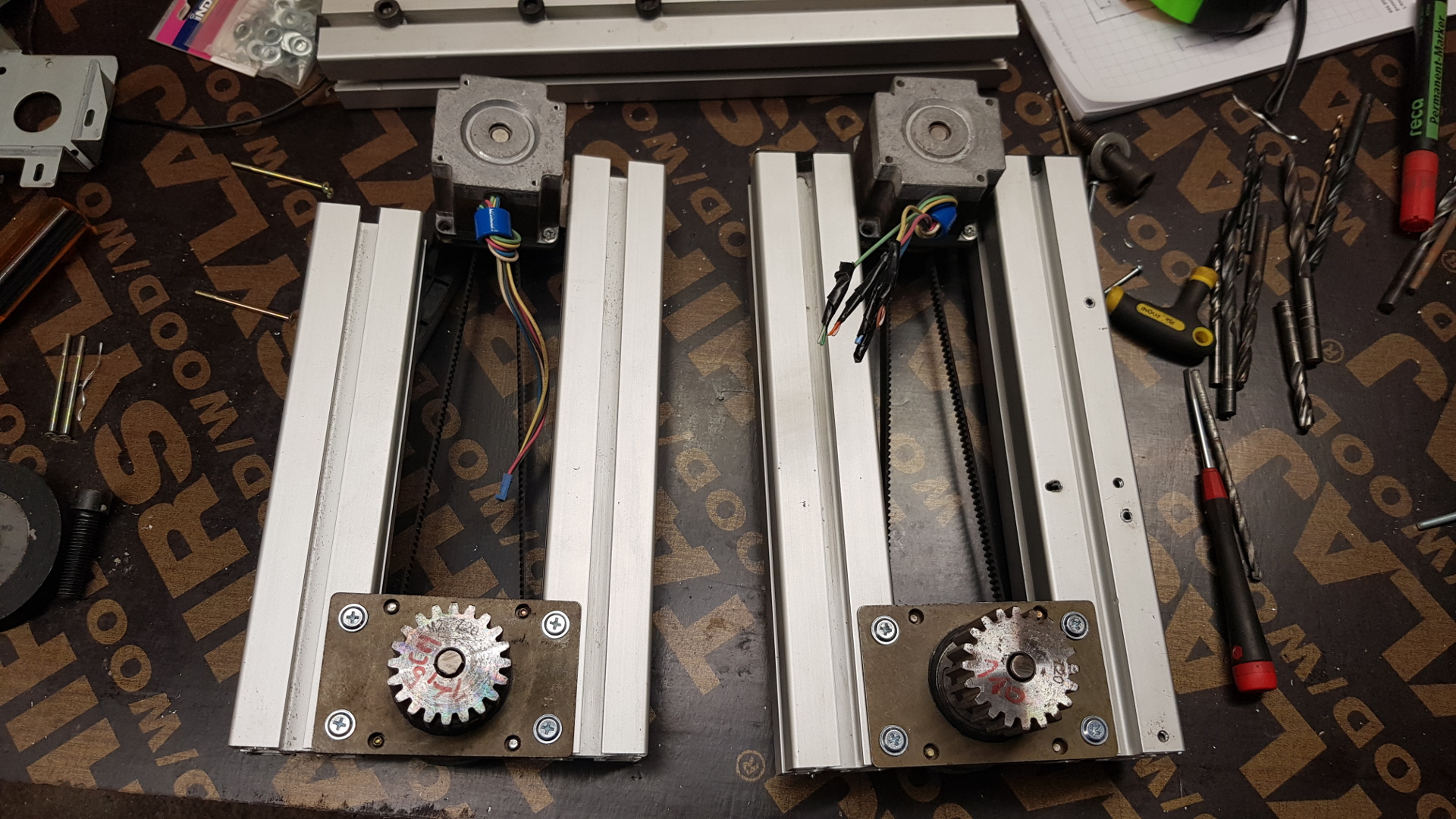

Here are some details of the reductions on both sides:

Other side

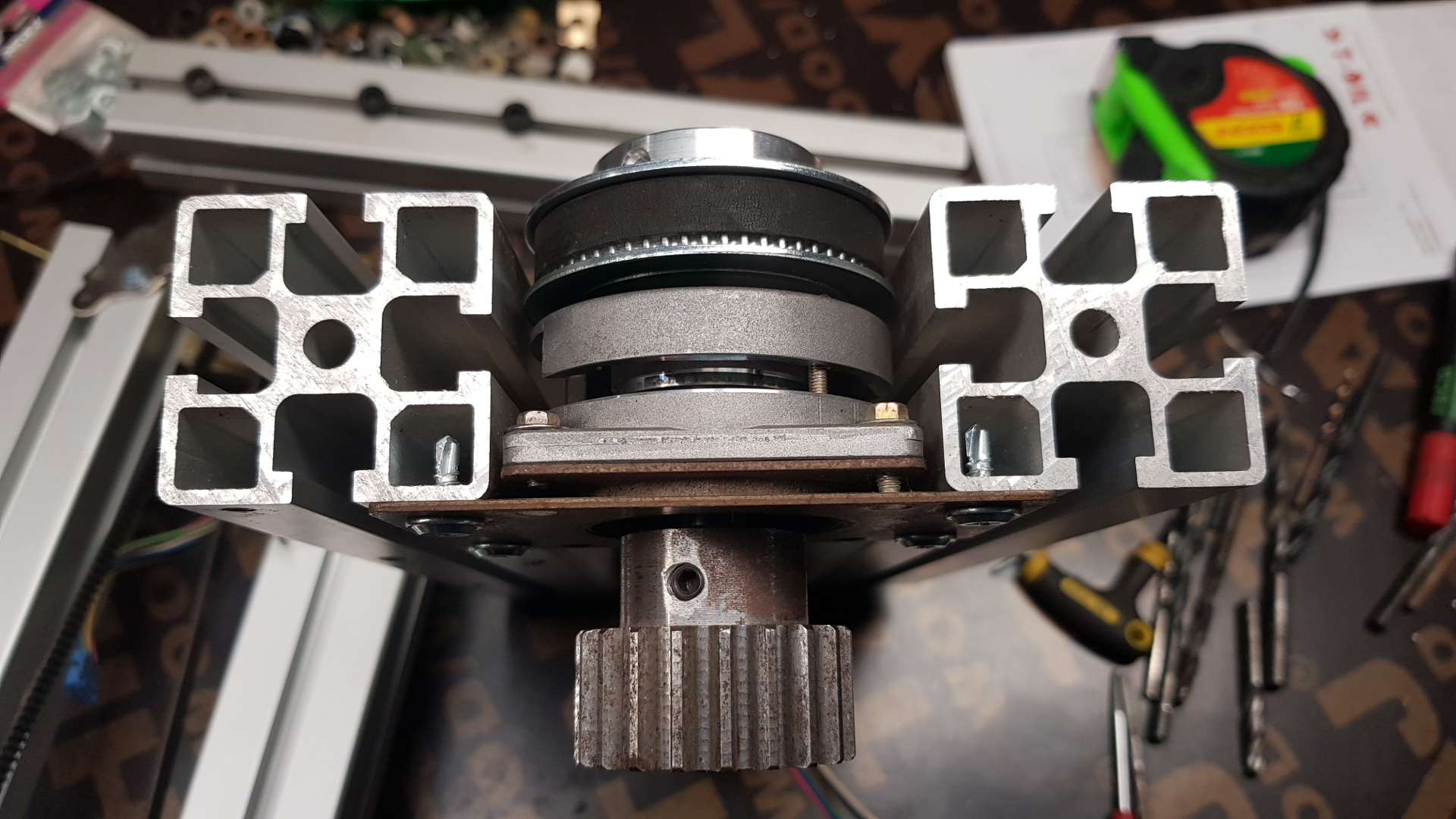

Bottom part where the pinion and the big pulley are mounted, gutted two healthy Vexta 5 phase steppers to get the bearing holders and bearings that did the job perfectly:

This is how the frame looked yesterday:

Another shot of the reduction in place:

Regards,

Tom.

P.S.

Adding pictures to this topic also, later.

forum.linuxcnc.org/plasma-laser/35349-op...ea-and-a-lot-of-info

Video of moving gantry here:

Video of it cutting here:

The machine dimensions are 4.2X1.75 meters, cut area will end up to 3.6X1.35 meters, so big enough.

Here are some details of the reductions on both sides:

Other side

Bottom part where the pinion and the big pulley are mounted, gutted two healthy Vexta 5 phase steppers to get the bearing holders and bearings that did the job perfectly:

This is how the frame looked yesterday:

Another shot of the reduction in place:

Regards,

Tom.

P.S.

Adding pictures to this topic also, later.

forum.linuxcnc.org/plasma-laser/35349-op...ea-and-a-lot-of-info

Video of moving gantry here:

Video of it cutting here:

Attachments:

Last edit: 08 Feb 2020 20:29 by tommylight. Reason: add video link

The following user(s) said Thank You: phillc54, chimeno, Clive S

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

27 Oct 2019 20:00 #148923

by thefabricator03

Replied by thefabricator03 on topic 3.5X1.5 Meters cnc plasma cutter

Looking good so far Tom,

Cant wait to see it in action!

Cant wait to see it in action!

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

27 Oct 2019 20:18 #148924

by machinedude

Replied by machinedude on topic 3.5X1.5 Meters cnc plasma cutter

slightly bigger than what i have going on and it probably took you a week to toss it together compared to my 3 months of building  i'm amazed by the ability to toss it together so quickly.

i'm amazed by the ability to toss it together so quickly.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

27 Oct 2019 20:36 #148925

by tommylight

Took me 5 days to make room for it as i had to rearrange the shop, to many things, waayyyyy to many things to move and clean !

This is my right hand after two days of drilling and taping hundreds of holes:

Back to work, no slouching allowed !

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

2 and a quarter days so far, full days from 10AM to 1AM!slightly bigger than what i have going on and it probably took you a week to toss it together compared to my 3 months of building

i'm amazed by the ability to toss it together so quickly.

Took me 5 days to make room for it as i had to rearrange the shop, to many things, waayyyyy to many things to move and clean !

This is my right hand after two days of drilling and taping hundreds of holes:

Back to work, no slouching allowed !

Attachments:

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

27 Oct 2019 20:43 #148928

by machinedude

Replied by machinedude on topic 3.5X1.5 Meters cnc plasma cutter

at least you did not bust a finger tip like me so be thankful. i give you credit on speed of assembly. wish i was able to work like that sometimes.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

27 Oct 2019 22:02 #148933

by Clive S

Replied by Clive S on topic 3.5X1.5 Meters cnc plasma cutter

Tom glad to see you got your mojo working again:)

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

27 Oct 2019 22:24 #148935

by tommylight

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

I quit the job at that factory, got tired of waiting for parts as they were miss handled by that Russian guy, for 3 years he did nothing!

I am to old to be waiting for anything any more!

I am to old to be waiting for anything any more!

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

28 Oct 2019 21:01 #149004

by tommylight

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

Here is a video of the gantry moving at over 30meters/minute.

The following user(s) said Thank You: phillc54, chimeno, thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

28 Oct 2019 21:51 #149008

by thefabricator03

Replied by thefabricator03 on topic 3.5X1.5 Meters cnc plasma cutter

What kind of power supplies are you using Tom? Are they switch mode units or torodial?

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

28 Oct 2019 22:08 #149010

by machinedude

Replied by machinedude on topic 3.5X1.5 Meters cnc plasma cutter

any reason why it's running on the Z axis or is that just for testing movement until everything is configured and finalized?

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.354 seconds