3.5X1.5 Meters cnc plasma cutter

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

28 Oct 2019 22:55 - 28 Oct 2019 23:09 #149017

by tommylight

Switch mode, china made V-Tac. A friend of mine is the importer for that company and a while back he asked me to test 7 types of SMPS from different manufacturers, these came out on top. They are 400W each, way to much for what i need, but the next lowest i got are 200W and that would be on the lower limit.

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

What kind of power supplies are you using Tom? Are they switch mode units or torodial?

Switch mode, china made V-Tac. A friend of mine is the importer for that company and a while back he asked me to test 7 types of SMPS from different manufacturers, these came out on top. They are 400W each, way to much for what i need, but the next lowest i got are 200W and that would be on the lower limit.

Last edit: 28 Oct 2019 23:09 by tommylight. Reason: Forgot the quote

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

28 Oct 2019 23:08 #149019

by tommylight

Those drives have to be programmed using a USB dongle, and i just wanted to do a quick test.

I do have another set of drives ready that is going to be used on this machine with the PC and everything, but i have preemp-rt installed in it and a parallel port so i could not test faster than 7 meters/minute for now and the drives are set at 8 and 16 microsteps. Need to install RTAI tomorrow and give it a go, should do much faster.

Also the rack are held by clamps so when i pushed it to 36m/m it started to shake a bit. I am eager to put the rack in place and give it another go, probably over 40m/m easily.

Stay tuned !

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

Z axis has the smaller drive, 4A RMS or 5.6A peak @48V, and i had it set at 2.5A so with two parallel wired motors that gave 1.25A per motor. The other two drives are 6A RMS or 8.6A peak and i had them set at 5 and 6A so it would be to much for those tiny motors. Also this setup uses the Mesa 7i92 with a very fast BOB, all round a very nice setup that can do very high speeds even with microstepping set very high. This will go on the big machine (6X2.1M plus rotary 4th axis) or on my mill, depending on my mood on what to finish first.any reason why it's running on the Z axis or is that just for testing movement until everything is configured and finalized?

Those drives have to be programmed using a USB dongle, and i just wanted to do a quick test.

I do have another set of drives ready that is going to be used on this machine with the PC and everything, but i have preemp-rt installed in it and a parallel port so i could not test faster than 7 meters/minute for now and the drives are set at 8 and 16 microsteps. Need to install RTAI tomorrow and give it a go, should do much faster.

Also the rack are held by clamps so when i pushed it to 36m/m it started to shake a bit. I am eager to put the rack in place and give it another go, probably over 40m/m easily.

Stay tuned !

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

29 Oct 2019 00:04 #149023

by thefabricator03

Replied by thefabricator03 on topic 3.5X1.5 Meters cnc plasma cutter

How do you think the switch mode units go compared to a torodal unit?

When I was building my machine I was not sure how a switch mode unit would go with back current from deceleration so I decided to go with the torodal unit.

When I was building my machine I was not sure how a switch mode unit would go with back current from deceleration so I decided to go with the torodal unit.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

29 Oct 2019 09:15 #149033

by rodw

I've had no issues with 48v switch mode (I had no idea where to find a toroidal). Also Homan Designs (the Aussies Gecko dealer) use switch mode on everything. I have a 48v 10 amp Meanwell with 3.5 amp Longs Motor DM542A controllers. which seem to be bulletproof.. even if only rated for 50 volts.

Replied by rodw on topic 3.5X1.5 Meters cnc plasma cutter

How do you think the switch mode units go compared to a torodal unit?

When I was building my machine I was not sure how a switch mode unit would go with back current from deceleration so I decided to go with the torodal unit.

I've had no issues with 48v switch mode (I had no idea where to find a toroidal). Also Homan Designs (the Aussies Gecko dealer) use switch mode on everything. I have a 48v 10 amp Meanwell with 3.5 amp Longs Motor DM542A controllers. which seem to be bulletproof.. even if only rated for 50 volts.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

29 Oct 2019 10:32 #149039

by tommylight

As for back EMF, i do have some switch mode power supplies with multiple output voltages that do not like that at all and they need a chill time of 10 to 15 minutes after such an event.

Never had such an issue with any other SMPS and laptop bricks.

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

They do work nicely, but do avoid the cheap ones, they are made by someone with no electronic experience at all and lack all kinds of protections and output control.How do you think the switch mode units go compared to a torodal unit?

When I was building my machine I was not sure how a switch mode unit would go with back current from deceleration so I decided to go with the torodal unit.

As for back EMF, i do have some switch mode power supplies with multiple output voltages that do not like that at all and they need a chill time of 10 to 15 minutes after such an event.

Never had such an issue with any other SMPS and laptop bricks.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

30 Oct 2019 23:13 #149236

by tommylight

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

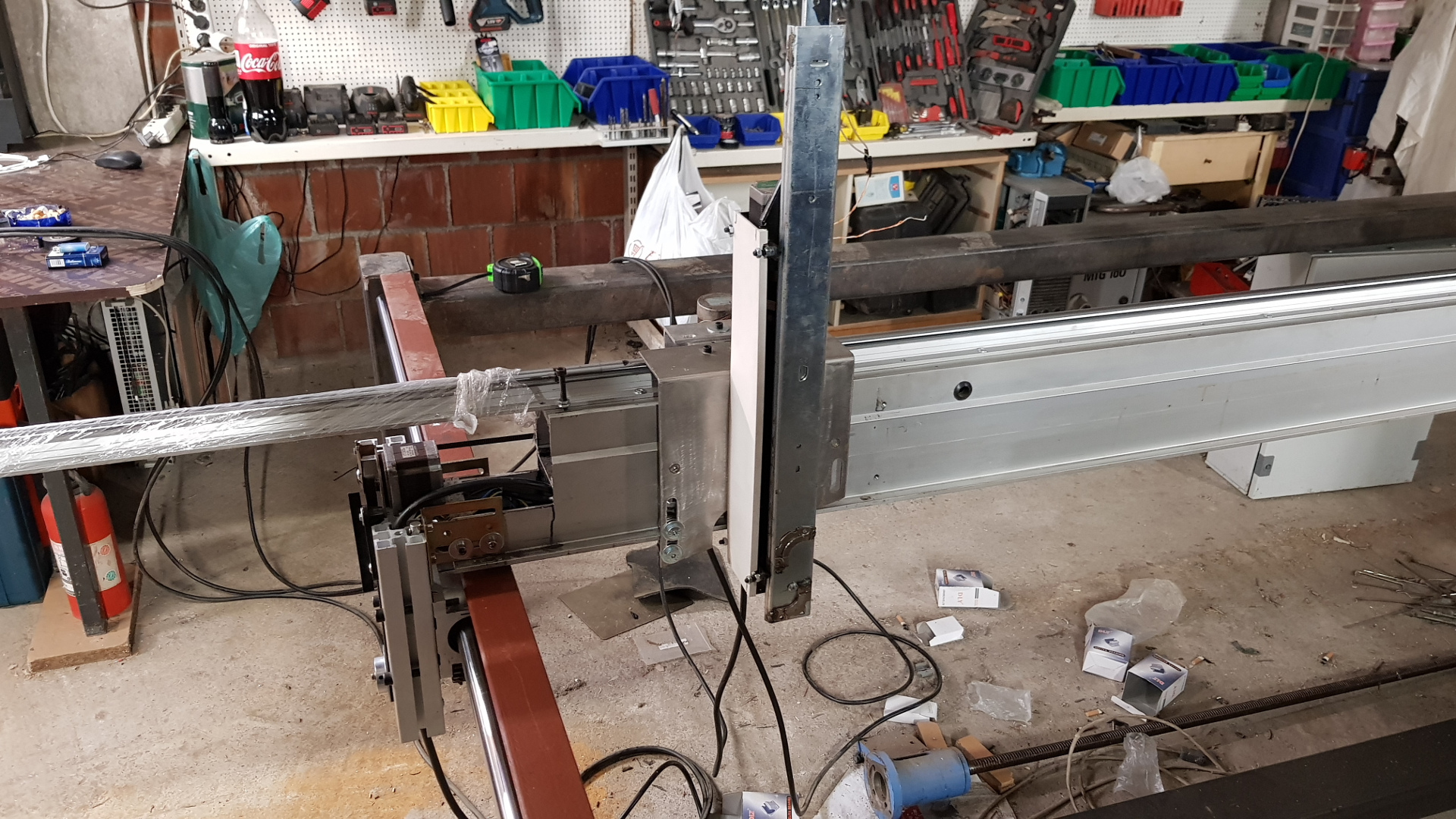

Z axis is mounted with floating switch and fully enclosed, Y axis has some more work to be done like cutting the rail, adding another one, etc. Reduction is finished and working with a temporary motor attached, can not find the wide belt i have somewhere hidden.....

Z axis can do 12 m/m easily !

Computer and electronics are done waiting for a box to put them in.

Now to dismantle everything and send it to paint, then mount everything back, add side and front panels to make it look nice. All in all, it's looking much better than i initially thought, mainly due to me thinking a lot before screwing something to it and later regretting it, thinking about how it will look at the end and how the panels will be mounted, avoiding getting in my own way with parts and later finding out it interferes with something else, etc, etc

Here are some more details:

Regards,

Tom.

Z axis can do 12 m/m easily !

Computer and electronics are done waiting for a box to put them in.

Now to dismantle everything and send it to paint, then mount everything back, add side and front panels to make it look nice. All in all, it's looking much better than i initially thought, mainly due to me thinking a lot before screwing something to it and later regretting it, thinking about how it will look at the end and how the panels will be mounted, avoiding getting in my own way with parts and later finding out it interferes with something else, etc, etc

Here are some more details:

Regards,

Tom.

Attachments:

The following user(s) said Thank You: phillc54, Clive S, thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

30 Oct 2019 23:17 - 30 Oct 2019 23:18 #149237

by thefabricator03

Replied by thefabricator03 on topic 3.5X1.5 Meters cnc plasma cutter

Tom,

Do you draw these tables in CAD before you build them or do you just get the design in your minds eye and go from there?

Do you draw these tables in CAD before you build them or do you just get the design in your minds eye and go from there?

Last edit: 30 Oct 2019 23:18 by thefabricator03.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

31 Oct 2019 00:11 #149242

by tommylight

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

Thank you.

Mostly from what i can find in the shop and in my head ( exceptionally big head, or was it a small body??? ).

).

I am not good at cad, last i used it was in the 90's, and even then i was not good but i was pretty damn good at 3DS Max, assembly, GWBasic, Corel, and some other things, and even started using Maya! Now i am learning Blender as it is hands down the best open source and free software, bar none, as can be seen by huge amounts of money being pored into it's development and the best thing is it has a CAM version. The downside is, it is hard to learn especially with the time constraints.

Am working on two cnc machines and already thinking and preparing parts for the third and the fourth, so it is relentless.....or i am relentless ???

Regards,

Tom.

Mostly from what i can find in the shop and in my head ( exceptionally big head, or was it a small body???

I am not good at cad, last i used it was in the 90's, and even then i was not good but i was pretty damn good at 3DS Max, assembly, GWBasic, Corel, and some other things, and even started using Maya! Now i am learning Blender as it is hands down the best open source and free software, bar none, as can be seen by huge amounts of money being pored into it's development and the best thing is it has a CAM version. The downside is, it is hard to learn especially with the time constraints.

Am working on two cnc machines and already thinking and preparing parts for the third and the fourth, so it is relentless.....or i am relentless ???

Regards,

Tom.

The following user(s) said Thank You: Clive S, thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

31 Oct 2019 00:52 #149245

by thefabricator03

Replied by thefabricator03 on topic 3.5X1.5 Meters cnc plasma cutter

Its great to see your progress and most importantly pictures.

I post pictures because when I am I designing something, looking at pictures of similar designs really come in handy. I hope that I can help others doing the same thing.

I use a 3d modeling software everyday called Tekla Structures. It is mostly for structural steel but I have used it on a couple of machine projects. One very handy features is that is has all the common structural tubes and plates available in its library so it is very easy to design a machine based on common materials.

And the best thing is getting really accurate weights of components, it even calculates the weight of weld material. Comes in handy when working out a gantry weight.

I post pictures because when I am I designing something, looking at pictures of similar designs really come in handy. I hope that I can help others doing the same thing.

I use a 3d modeling software everyday called Tekla Structures. It is mostly for structural steel but I have used it on a couple of machine projects. One very handy features is that is has all the common structural tubes and plates available in its library so it is very easy to design a machine based on common materials.

And the best thing is getting really accurate weights of components, it even calculates the weight of weld material. Comes in handy when working out a gantry weight.

Please Log in or Create an account to join the conversation.

- HueyHQ

-

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

31 Oct 2019 04:06 #149258

by HueyHQ

Are you able to give any good YouTube references for Blender CAM? There are a small number of them there, I see, but wondering if any you would recommend.

Is it capable of 4th and 5th axis CAM? If so, I think I would rather learn Blender and Fusion 360 when the time comes.

Replied by HueyHQ on topic 3.5X1.5 Meters cnc plasma cutter

Hi Tom,Now i am learning Blender as it is hands down the best open source and free software, bar none, as can be seen by huge amounts of money being pored into it's development and the best thing is it has a CAM version.

Are you able to give any good YouTube references for Blender CAM? There are a small number of them there, I see, but wondering if any you would recommend.

Is it capable of 4th and 5th axis CAM? If so, I think I would rather learn Blender and Fusion 360 when the time comes.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.359 seconds