3.5X1.5 Meters cnc plasma cutter

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

31 Oct 2019 08:23 #149263

by Clive S

Replied by Clive S on topic 3.5X1.5 Meters cnc plasma cutter

@Tom I see you are still on the cola and off the coffee

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

31 Oct 2019 10:48 #149275

by tommylight

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

@Thefabricator,

That sounds nice, but i am sure it will take me 2 to 3 days to make something useful in 3D, in that time i can have half the machine done! The main issue is i can not source good material, even the metal profiles are the lowest quality possible, so when i find something decent i have to make do with it.

As for the gantry, this is salvaged from a plotter so it is thick aluminium and it had another part used on another machine at the same 432cm length.

@HueyHQ

Not really, there are some not so good, but there are plenty of very good ones for Blender now.

I think it is capable of 5 axis stuff, but never got the time to test it. I recall having a lot of settings for the cnc side of things, like a lot!

Here is the link:

blendercam.blogspot.com/p/download-and-installation.html

These are the dependencies needed for it to work

sudo apt-get install libgeos-dev

sudo apt-get install python3-dev

And do not follow the instructions there, just go to google drive and download the version you need, it is already set up completely.

@CliveS

Yes i am, although i can drink those 2in1 or 3in1 powder things, but not espresso! Still have no clue as to how and why that happened, i really enjoyed drinking it. Getting old !

That sounds nice, but i am sure it will take me 2 to 3 days to make something useful in 3D, in that time i can have half the machine done! The main issue is i can not source good material, even the metal profiles are the lowest quality possible, so when i find something decent i have to make do with it.

As for the gantry, this is salvaged from a plotter so it is thick aluminium and it had another part used on another machine at the same 432cm length.

@HueyHQ

Not really, there are some not so good, but there are plenty of very good ones for Blender now.

I think it is capable of 5 axis stuff, but never got the time to test it. I recall having a lot of settings for the cnc side of things, like a lot!

Here is the link:

blendercam.blogspot.com/p/download-and-installation.html

These are the dependencies needed for it to work

sudo apt-get install libgeos-dev

sudo apt-get install python3-dev

And do not follow the instructions there, just go to google drive and download the version you need, it is already set up completely.

@CliveS

Yes i am, although i can drink those 2in1 or 3in1 powder things, but not espresso! Still have no clue as to how and why that happened, i really enjoyed drinking it. Getting old !

The following user(s) said Thank You: Clive S, HueyHQ

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

31 Oct 2019 11:27 #149277

by pl7i92

Replied by pl7i92 on topic 3.5X1.5 Meters cnc plasma cutter

as off todays Halooween 3D work

supperfast 3D prints

supperfast 3D prints

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

01 Nov 2019 16:21 #149372

by tommylight

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

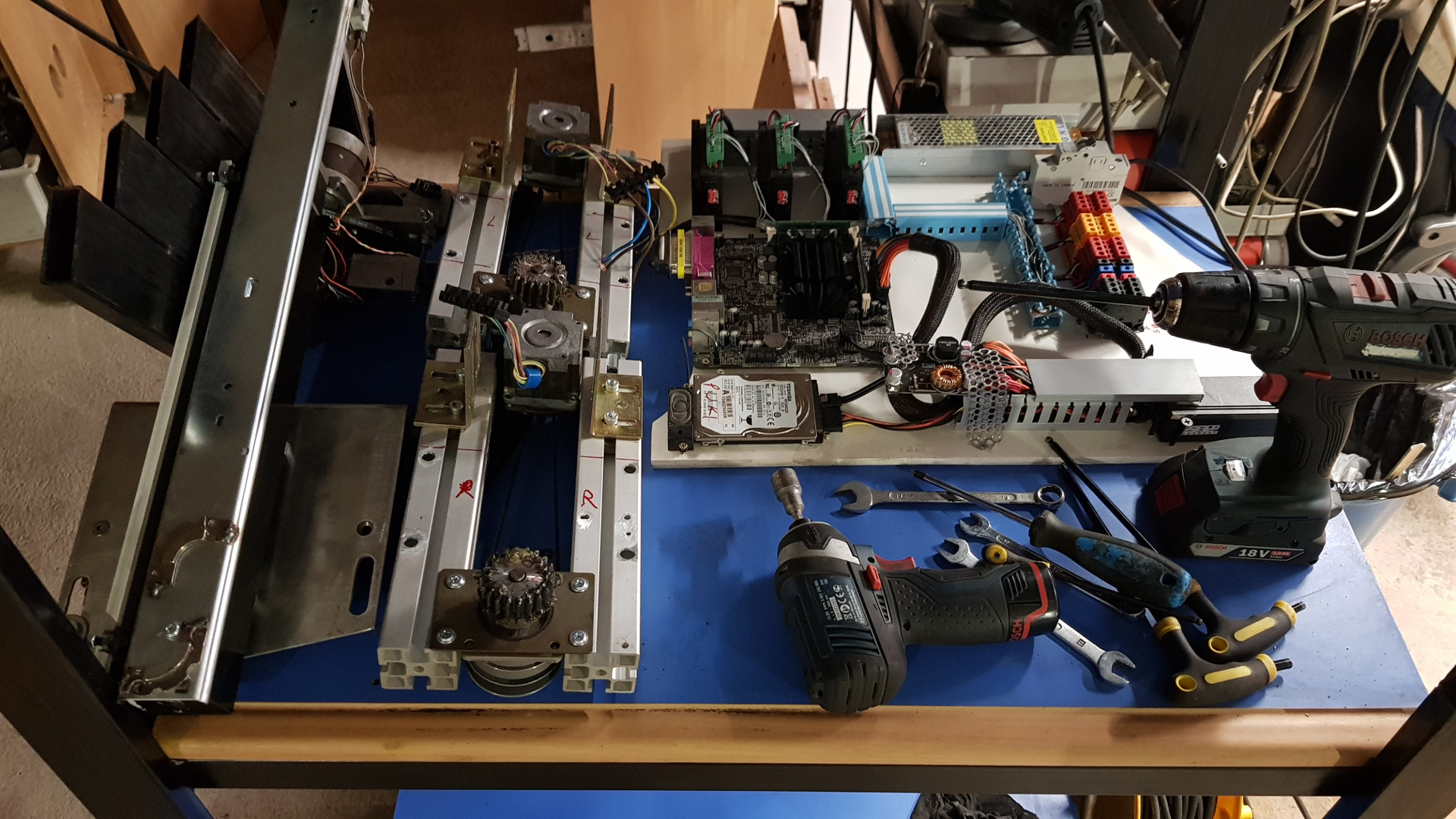

As ZZTop would say "the thrill is goneeeee", well the machine is dismantled and waiting to be painted tomorrow, hopefully. Oh, both machines are waiting to be painted.

The good thing, now the shop look's big and empty! Not for long, for sure.

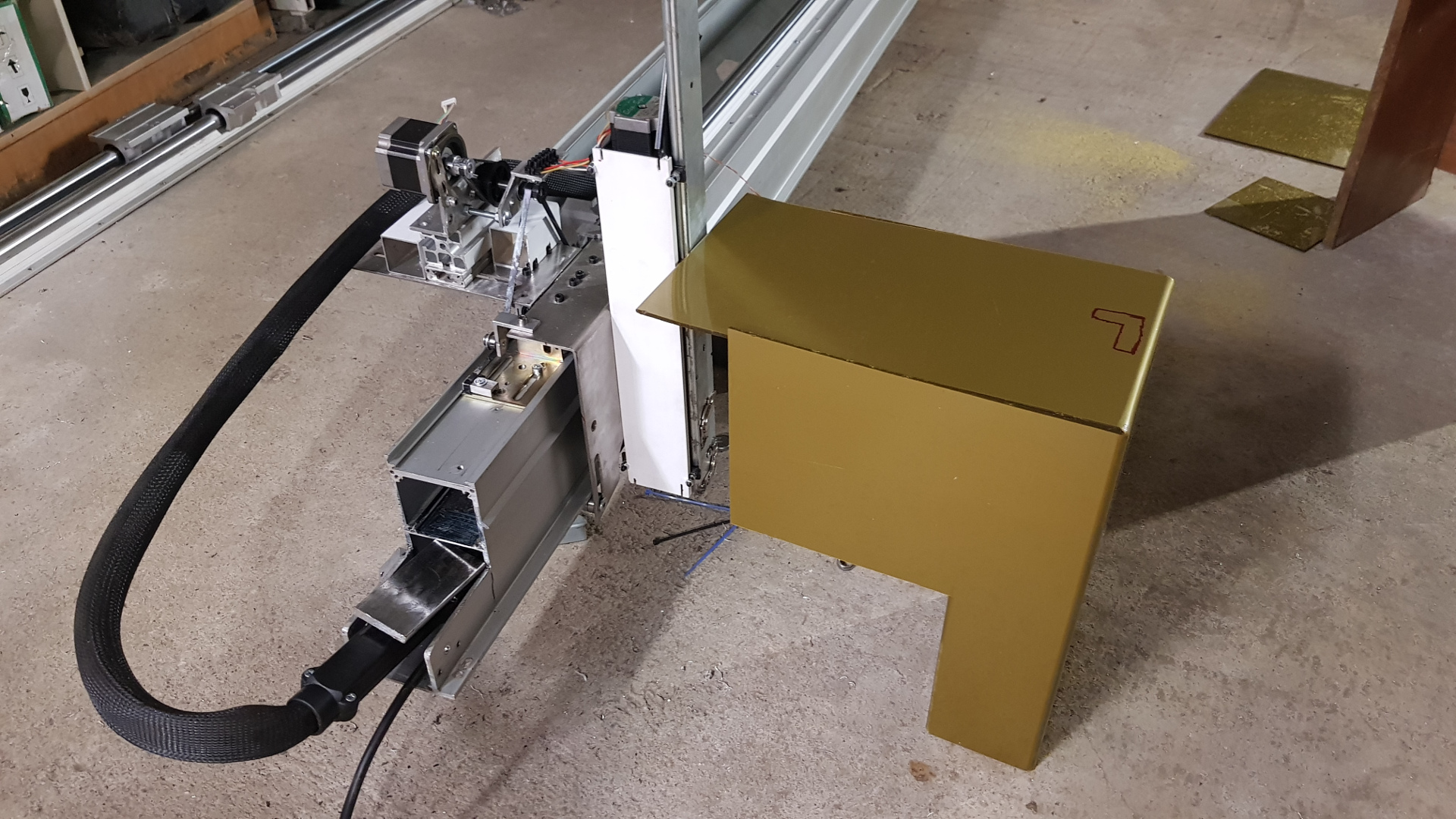

Now we have a lonely and empty, dare i say "naked" gantry waiting patiently to have a lot of stuff bolted to it:

And here are some of the parts to be glued to it:

Will try to take pictures as much as possible, but i might forget while i am working on it, i usually do!

Regards,

Tom.

The good thing, now the shop look's big and empty! Not for long, for sure.

Now we have a lonely and empty, dare i say "naked" gantry waiting patiently to have a lot of stuff bolted to it:

And here are some of the parts to be glued to it:

Will try to take pictures as much as possible, but i might forget while i am working on it, i usually do!

Regards,

Tom.

Attachments:

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

01 Nov 2019 19:47 #149386

by machinedude

Replied by machinedude on topic 3.5X1.5 Meters cnc plasma cutter

Tom you are a machine. i tried to get some work done on mine this week but crashed and burned yesterday and got nothing accomplished. i did manage to pick up some paint and more material today.the way things are sitting now for me i need more structure in my frame. another set of casters in the middle are a must and i am sure the cross sections will beef things up once i get those in. i did pick up a refurbished DELL 780 to mess around with Linux but have not had time to mess with it yet. it does have a printer port and a serial port with plenty of USB ports.

i wish i had more time for my project but i still need the regular job to keep the lights on not to mention the weather dropped like 20 degrees yesterday and feels like winter is not far off. i'm running out of warm weather and might need to start winterizing the shop so i can at least try to heat it when it gets really cold

not to mention the weather dropped like 20 degrees yesterday and feels like winter is not far off. i'm running out of warm weather and might need to start winterizing the shop so i can at least try to heat it when it gets really cold

i feel like i'm moving in slow motion watching you go

i wish i had more time for my project but i still need the regular job to keep the lights on

i feel like i'm moving in slow motion watching you go

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

02 Nov 2019 01:19 - 02 Nov 2019 01:19 #149402

by tommylight

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

Supporting properly a plasma table is a must, after repeated dumping of metal plates it tends to sag and bend, although having a THC negates that quite a bit.

Those Dell's are really nice, had plenty of them and they never fail, but for some reason i can not find them anymore, they just vanished !

It was sunny till 2 days ago, now it feels like winter already and it gets dark a smudge after 5PM but i do not heat the shop, i get used to it, well till it gets to bellow -11C outside, inside is still above zero due to some computers that are on 24h/day.

Still waiting for painted parts, did some other things today, mounted permanently one of the rails on the gantry, did some modifications to the Z axis holders, modified a bit the reduction and changed the motor for a new one, checking everything again to make sure there is no point of failure lurking, etc.

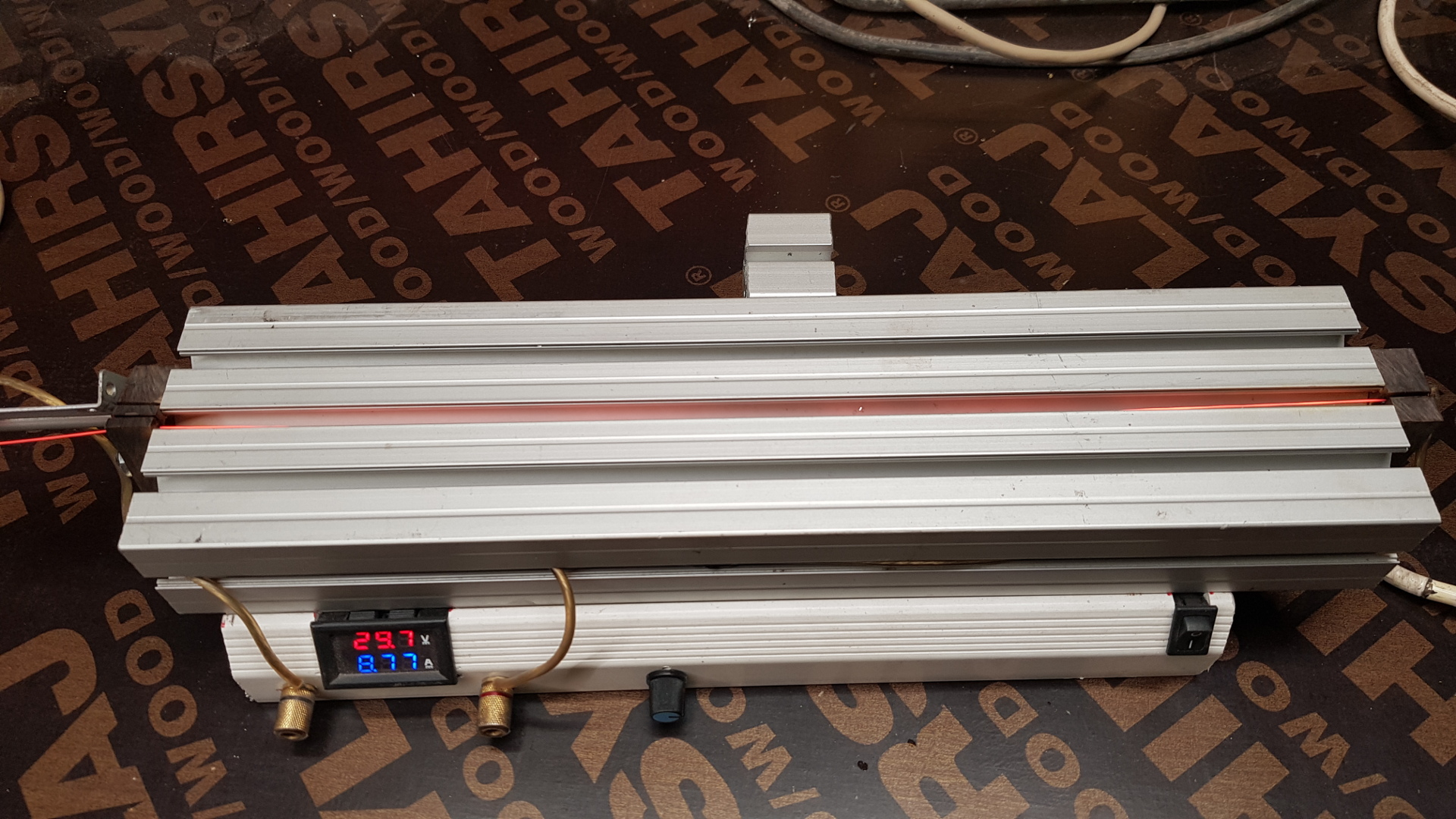

Also built a small heater on an aluminium profile for bending plastic, used some thin guitar strings as a heating element, will come in handy when assembling the machines to make them look good.

Started building 4th axis for this machine as i found some nice gears and chain with a ratio of 1:5.6, should do nicely powered by a 3NM stepper motor for cutting round tubes. Need two more of these as i already did one such reduction last year and it did work properly up to 200mm diameter. The only thing i do not like is that i have to use lathe chucks and they are bloody heavy so the acceleration has to be quite low.

Off to bed, it's 2:19 AM here.

Those Dell's are really nice, had plenty of them and they never fail, but for some reason i can not find them anymore, they just vanished !

It was sunny till 2 days ago, now it feels like winter already and it gets dark a smudge after 5PM but i do not heat the shop, i get used to it, well till it gets to bellow -11C outside, inside is still above zero due to some computers that are on 24h/day.

Still waiting for painted parts, did some other things today, mounted permanently one of the rails on the gantry, did some modifications to the Z axis holders, modified a bit the reduction and changed the motor for a new one, checking everything again to make sure there is no point of failure lurking, etc.

Also built a small heater on an aluminium profile for bending plastic, used some thin guitar strings as a heating element, will come in handy when assembling the machines to make them look good.

Started building 4th axis for this machine as i found some nice gears and chain with a ratio of 1:5.6, should do nicely powered by a 3NM stepper motor for cutting round tubes. Need two more of these as i already did one such reduction last year and it did work properly up to 200mm diameter. The only thing i do not like is that i have to use lathe chucks and they are bloody heavy so the acceleration has to be quite low.

Off to bed, it's 2:19 AM here.

Last edit: 02 Nov 2019 01:19 by tommylight.

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

02 Nov 2019 10:41 #149422

by machinedude

Replied by machinedude on topic 3.5X1.5 Meters cnc plasma cutter

i never gave a 4th axis a thought for plasma but that is something not as common to have available to you which makes it a plus. i could probably get some things done with it since i have some more travel on my Z axis than most. i've seen weldments needing work after bending and welding so the need to have some reach down inside of things was something i was thinking about from the beginning. travel on my Z axis is about 10 inches max but that might be enough to get some kind of rotary work under? something to think about.

when dealing with shafts or tubes a chuck on one end and some sort of center on the other end is one way to hold them. the only other way i can think of for a second option is between two centers with the use of a slotted face plate and a lathe dog to drive the shaft or tube. that might be a little lighter but not as quick when it come to changing parts out. the only other thing i can think of off hand would be use a smaller chuck that grips the ID of the tube rather than the outside so you could keep your chuck as small as possible.

i had a job making industrial pumps and we made some pretty big shafts for those. most were around 16 feet long, we did all of the turning between two dead centers and used 3 steady rests at once since the run out had to be around .0002(english) or better. but before you could do any work on a shaft they would have to have to be center drilled on the ends. we used a fixture to get those started on the ends. we would drive them in a 3 jaw on one end and used the fixture on the other end so we could get a center to hold the end not driven by the chuck ,spot a turn for a steady rest then add a steady rest so we could center the shaft. the fixture used to do this was just a tube with an ID big enough to fit over the size shaft being worked on, the end was closed off with a center in it for the tail stock but it had 4 bolts 90 degrees apart to adjust the shaft so it ran true somewhat. something like this to hold your tube might work but like i said changing the parts out in a production sense would not be very fast.

seems like they best way to over come the weight of the chuck is to just use bigger motors to to get the speeds you need. if not the best solution it's probably the easy way around it.

when dealing with shafts or tubes a chuck on one end and some sort of center on the other end is one way to hold them. the only other way i can think of for a second option is between two centers with the use of a slotted face plate and a lathe dog to drive the shaft or tube. that might be a little lighter but not as quick when it come to changing parts out. the only other thing i can think of off hand would be use a smaller chuck that grips the ID of the tube rather than the outside so you could keep your chuck as small as possible.

i had a job making industrial pumps and we made some pretty big shafts for those. most were around 16 feet long, we did all of the turning between two dead centers and used 3 steady rests at once since the run out had to be around .0002(english) or better. but before you could do any work on a shaft they would have to have to be center drilled on the ends. we used a fixture to get those started on the ends. we would drive them in a 3 jaw on one end and used the fixture on the other end so we could get a center to hold the end not driven by the chuck ,spot a turn for a steady rest then add a steady rest so we could center the shaft. the fixture used to do this was just a tube with an ID big enough to fit over the size shaft being worked on, the end was closed off with a center in it for the tail stock but it had 4 bolts 90 degrees apart to adjust the shaft so it ran true somewhat. something like this to hold your tube might work but like i said changing the parts out in a production sense would not be very fast.

seems like they best way to over come the weight of the chuck is to just use bigger motors to to get the speeds you need. if not the best solution it's probably the easy way around it.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

03 Nov 2019 01:24 - 03 Nov 2019 01:34 #149461

by tommylight

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

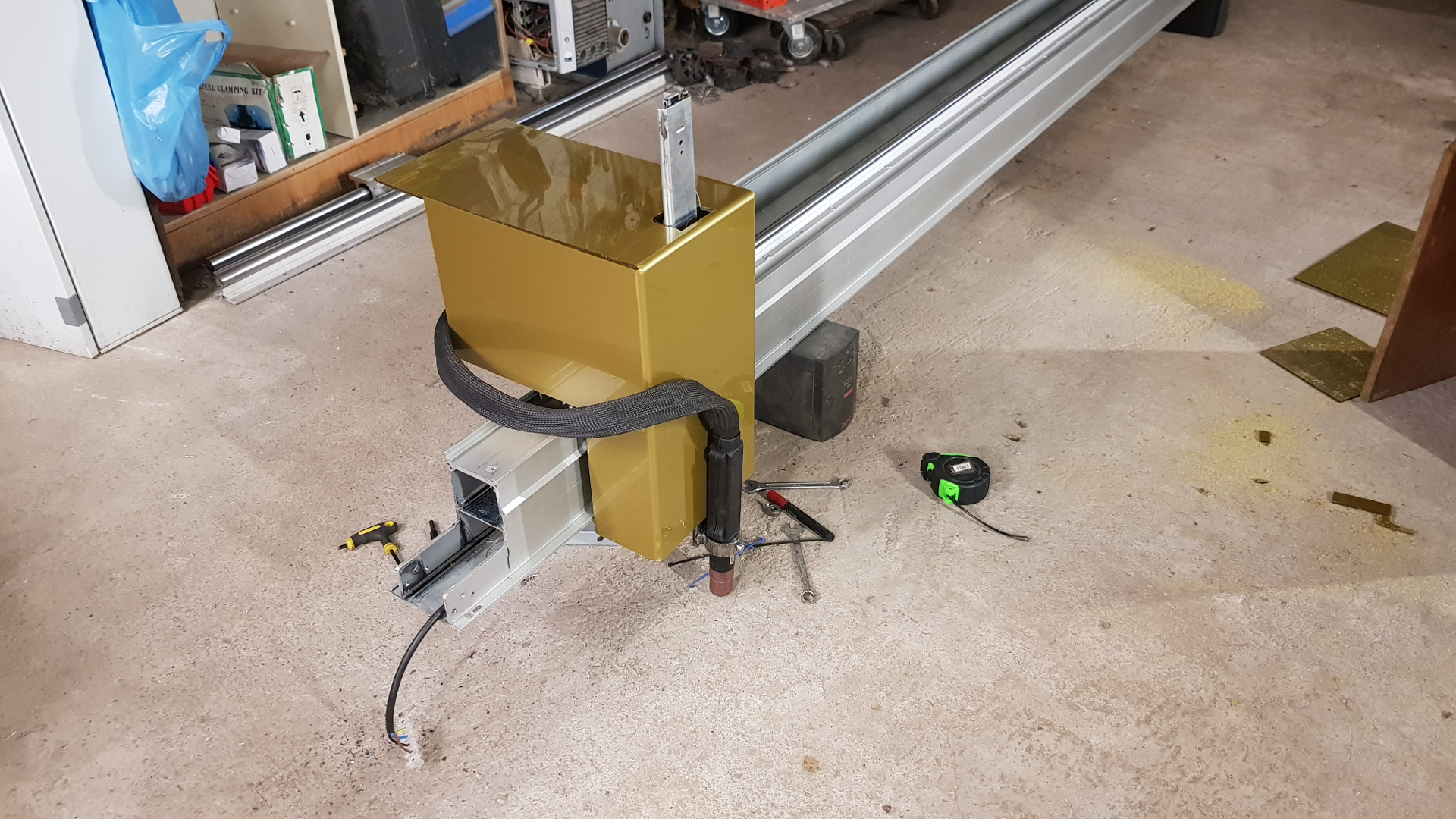

Waisted half of the day putting two bearings in place as i had to change the position of the motor and reduction! $H#t ! Also mounted the back side where the cables should reside, hence motor had to trade places.

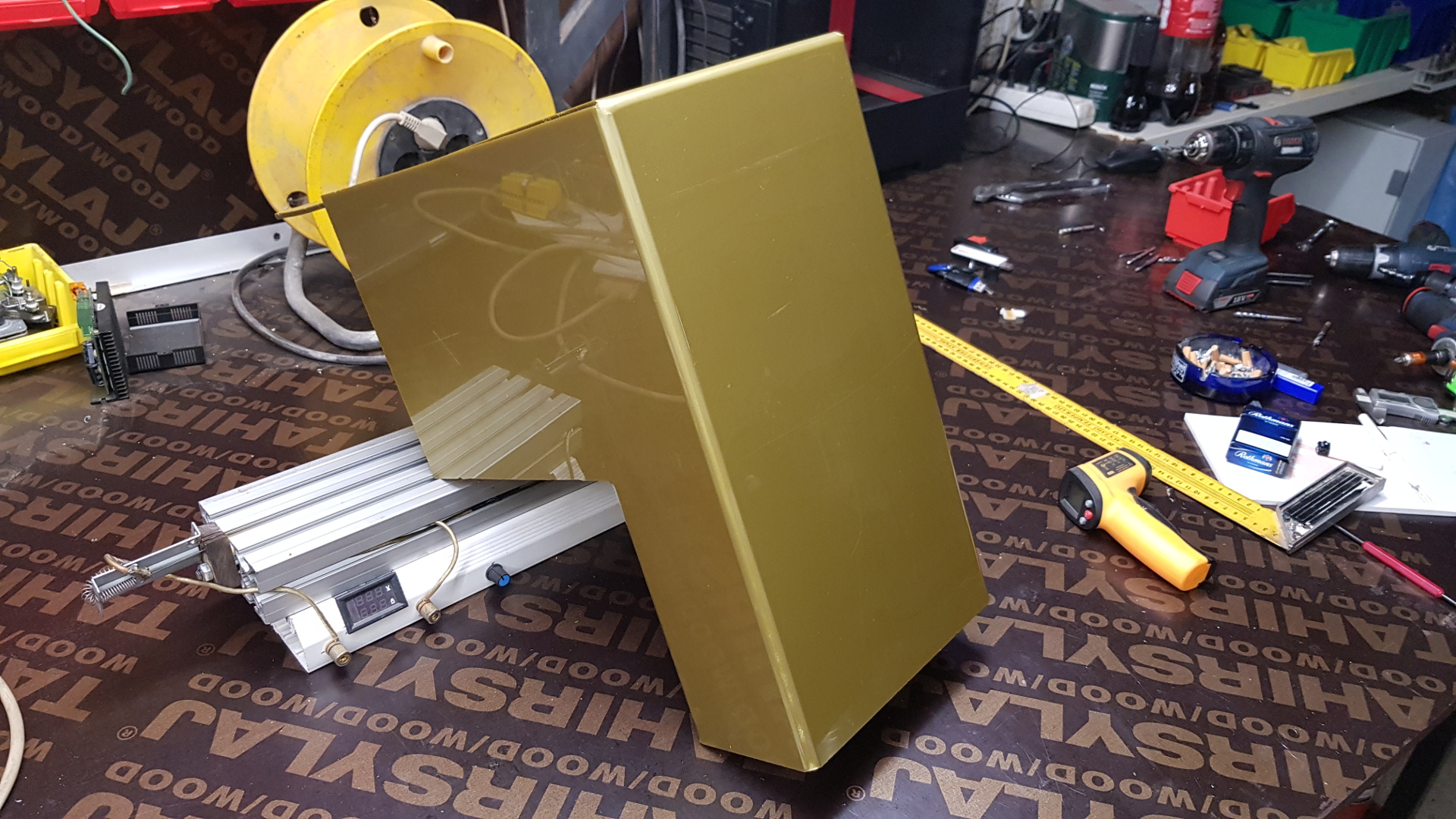

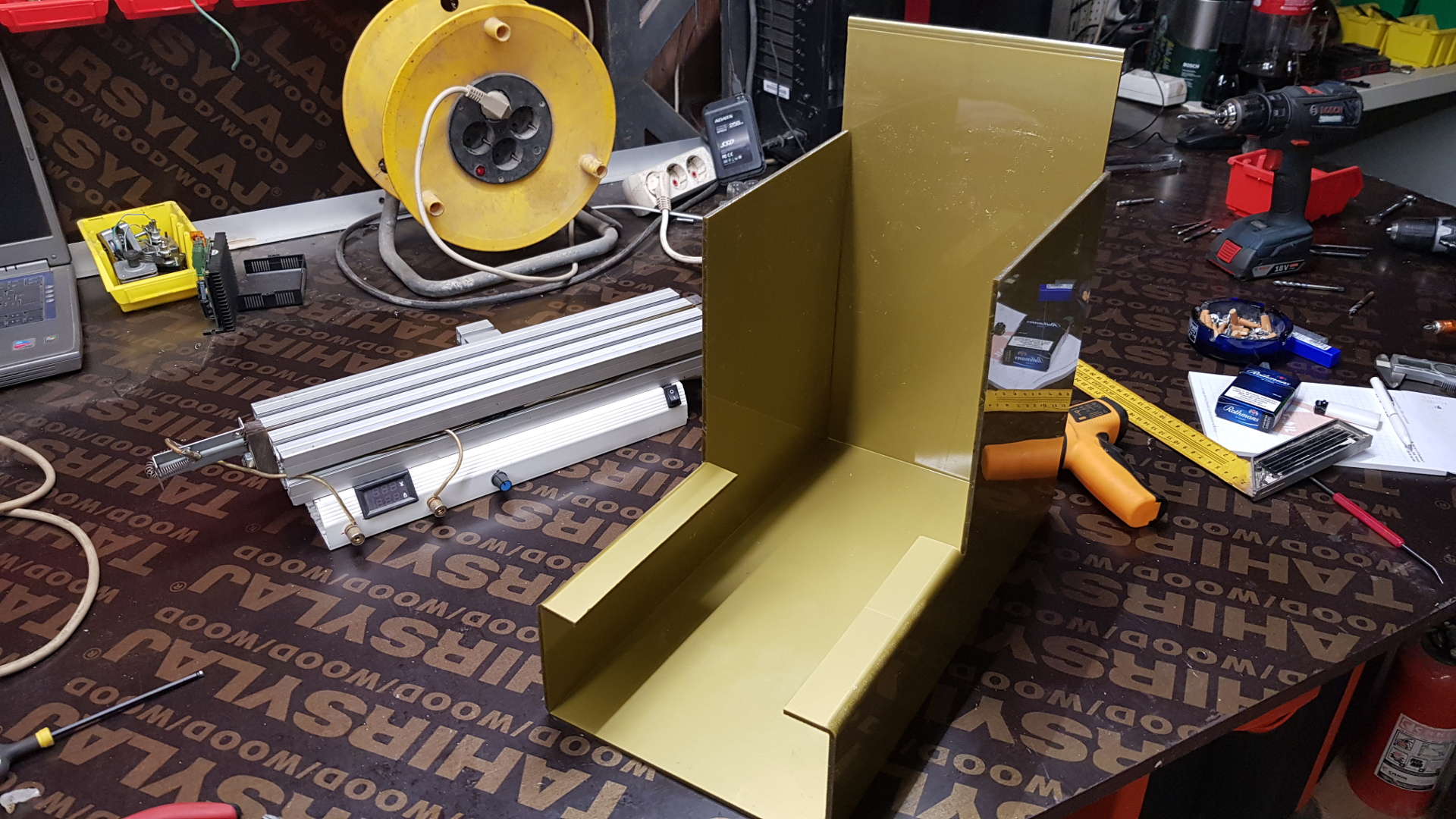

Evening was much more productive and painful as i burned both of my hands a bit working with plastic, remember i made a heater for bending plastic a while back ? Well i put it to good use today and here are the results:

Made out of a single piece of 5mm thick plastic, as fate would have it, that was the only piece big enough, i do have some white 2.5 and 3mm thick in smaller sizes, more on that later.

Back side of with flanges for mounting.

This is the "Machine" that does the heating, basically an adjustable power supply, a piece of aluminium 50X100mm and two thin guitar strings. Worked like a charm, as my hands can testify !

Some preliminary test fitting and marking for the protruding part.

New Trafimet autocut A141P torch. The body is from a cheap welding torch.

That same torch in it's rightful place.

Next post, it is 6 picture limit i think.

Evening was much more productive and painful as i burned both of my hands a bit working with plastic, remember i made a heater for bending plastic a while back ? Well i put it to good use today and here are the results:

Made out of a single piece of 5mm thick plastic, as fate would have it, that was the only piece big enough, i do have some white 2.5 and 3mm thick in smaller sizes, more on that later.

Back side of with flanges for mounting.

This is the "Machine" that does the heating, basically an adjustable power supply, a piece of aluminium 50X100mm and two thin guitar strings. Worked like a charm, as my hands can testify !

Some preliminary test fitting and marking for the protruding part.

New Trafimet autocut A141P torch. The body is from a cheap welding torch.

That same torch in it's rightful place.

Next post, it is 6 picture limit i think.

Attachments:

Last edit: 03 Nov 2019 01:34 by tommylight. Reason: more info

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

03 Nov 2019 01:33 #149463

by tommylight

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

A sip of Coke and a cig later, i am back,

And this is how it looks now:

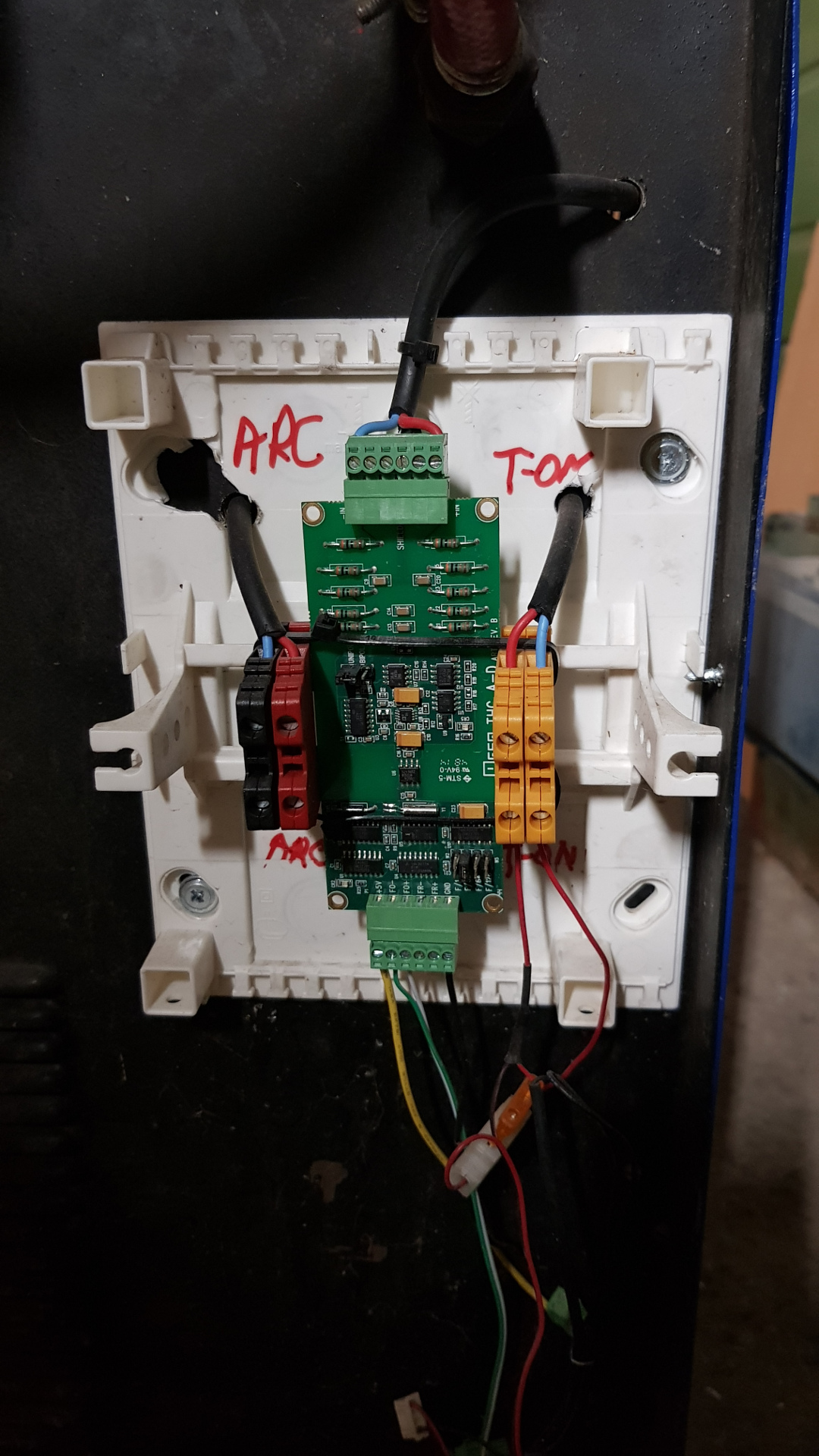

And this is the Mesa THCAD waiting eagerly to be put to use:

Now i need to find some shielded cable as i ran out of it a while back and i can not find any.

Oh, remember the protruding part mentioned above?

Well that is where a box with white plastic should reside, together with some LED lights inside so it glows white while the machine is on and red while in use and running.

2:32AM and i am still in the workshop, next in the agenda: sleeeeeeep !!!

And this is how it looks now:

And this is the Mesa THCAD waiting eagerly to be put to use:

Now i need to find some shielded cable as i ran out of it a while back and i can not find any.

Oh, remember the protruding part mentioned above?

Well that is where a box with white plastic should reside, together with some LED lights inside so it glows white while the machine is on and red while in use and running.

2:32AM and i am still in the workshop, next in the agenda: sleeeeeeep !!!

Attachments:

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

03 Nov 2019 13:30 #149488

by tommylight

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

Attachments:

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.432 seconds