3.5X1.5 Meters cnc plasma cutter

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

03 Nov 2019 15:30 #149496

by machinedude

Replied by machinedude on topic 3.5X1.5 Meters cnc plasma cutter

only half as much as you it seems  wish i was excited like you

wish i was excited like you  off to see what i can mess up today for a while on my junk. thinking since i have 8 leveling casters it might not be a bad idea to use them all rather than just a set in the middle while i'm back to the drawing board

off to see what i can mess up today for a while on my junk. thinking since i have 8 leveling casters it might not be a bad idea to use them all rather than just a set in the middle while i'm back to the drawing board

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

08 Nov 2019 16:54 #149928

by tommylight

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

Some progress:

Painted mat dark grey ( not my choice, but better than nothing)

Lettering on the gantry, both sides (despite me sending them an SVG with correct dimensions, they managed to mess up the dimensions! )

Pictures:

Front

Back

Been busy working on the small machine as i had to change it's designation from a plasma to an engraver, so i though it would be nice to add height adjustment and then also thought of making it motorised, so i keep complicating everything. Will upload pictures of that machine later.

Regards,

Tom.

Painted mat dark grey ( not my choice, but better than nothing)

Lettering on the gantry, both sides (despite me sending them an SVG with correct dimensions, they managed to mess up the dimensions! )

Pictures:

Front

Back

Been busy working on the small machine as i had to change it's designation from a plasma to an engraver, so i though it would be nice to add height adjustment and then also thought of making it motorised, so i keep complicating everything. Will upload pictures of that machine later.

Regards,

Tom.

Attachments:

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

08 Nov 2019 21:36 - 08 Nov 2019 21:39 #149941

by thefabricator03

Replied by thefabricator03 on topic 3.5X1.5 Meters cnc plasma cutter

As always Tom, looking good.

The sign writing has come up well.

Did you use a single pack paint or a two pack? Enamel or acrylic?

The sign writing has come up well.

Did you use a single pack paint or a two pack? Enamel or acrylic?

Last edit: 08 Nov 2019 21:39 by thefabricator03.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

08 Nov 2019 21:56 #149942

by tommylight

Lettering is adhesive foil, machine is some new type used here lately, i have no clue what or how as is stains a lot, like you can see fingerprints from 3 meters far !

Most of it is going to be covered by panels so eager to see how it looks at the end.

Thank you.

P.S.

Busy with this:

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

Not really, the lower part, right side the lettering is smaller than the left side, they should have been the same, that is why there is a void between them now.The sign writing has come up well.

Lettering or machine?Did you use a single pack paint or a two pack? Enamel or acrylic?

Lettering is adhesive foil, machine is some new type used here lately, i have no clue what or how as is stains a lot, like you can see fingerprints from 3 meters far !

Most of it is going to be covered by panels so eager to see how it looks at the end.

Thank you.

P.S.

Busy with this:

Attachments:

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

09 Nov 2019 08:28 #149969

by machinedude

Replied by machinedude on topic 3.5X1.5 Meters cnc plasma cutter

looks pretty nice on both machines. paint is typical soft for a while even after it is dry. it takes a while to fully cure.

i can't even paint this time of year because it's to cold without heat. once you hit 65 degrees that's about the bottom limit for painting anything, metal temp is about 15 degrees below what it is outside so that complicates finishes as well.

i'm curious about the industrial enamel i'm going to be using once i get that far.hopefully it is something durable enough? I've never used the industrial grade before so hopefully it's not much different than the automotive type.

what ever type you have it looks good in a picture, hopefully it was used with some type of hardener? if you notice fingerprints getting in it that's soft paint which is normal for a while but if it still is something you notice after about 3 or 4 weeks then the paint could just be that soft in general and that would be something i would expect with no hardener in the paint system.

looks good regardless.

i can't even paint this time of year because it's to cold without heat. once you hit 65 degrees that's about the bottom limit for painting anything, metal temp is about 15 degrees below what it is outside so that complicates finishes as well.

i'm curious about the industrial enamel i'm going to be using once i get that far.hopefully it is something durable enough? I've never used the industrial grade before so hopefully it's not much different than the automotive type.

what ever type you have it looks good in a picture, hopefully it was used with some type of hardener? if you notice fingerprints getting in it that's soft paint which is normal for a while but if it still is something you notice after about 3 or 4 weeks then the paint could just be that soft in general and that would be something i would expect with no hardener in the paint system.

looks good regardless.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

09 Nov 2019 14:31 #149985

by pl7i92

Replied by pl7i92 on topic 3.5X1.5 Meters cnc plasma cutter

is this a fully asambled mashine or does it come as a Kit without welding

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

09 Nov 2019 16:05 #149990

by tommylight

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

This one can be disassembled and transported as a 4.5X0.85X0.5 M box.

That is without the material table.

That is without the material table.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

11 Nov 2019 18:22 #150144

by tommylight

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

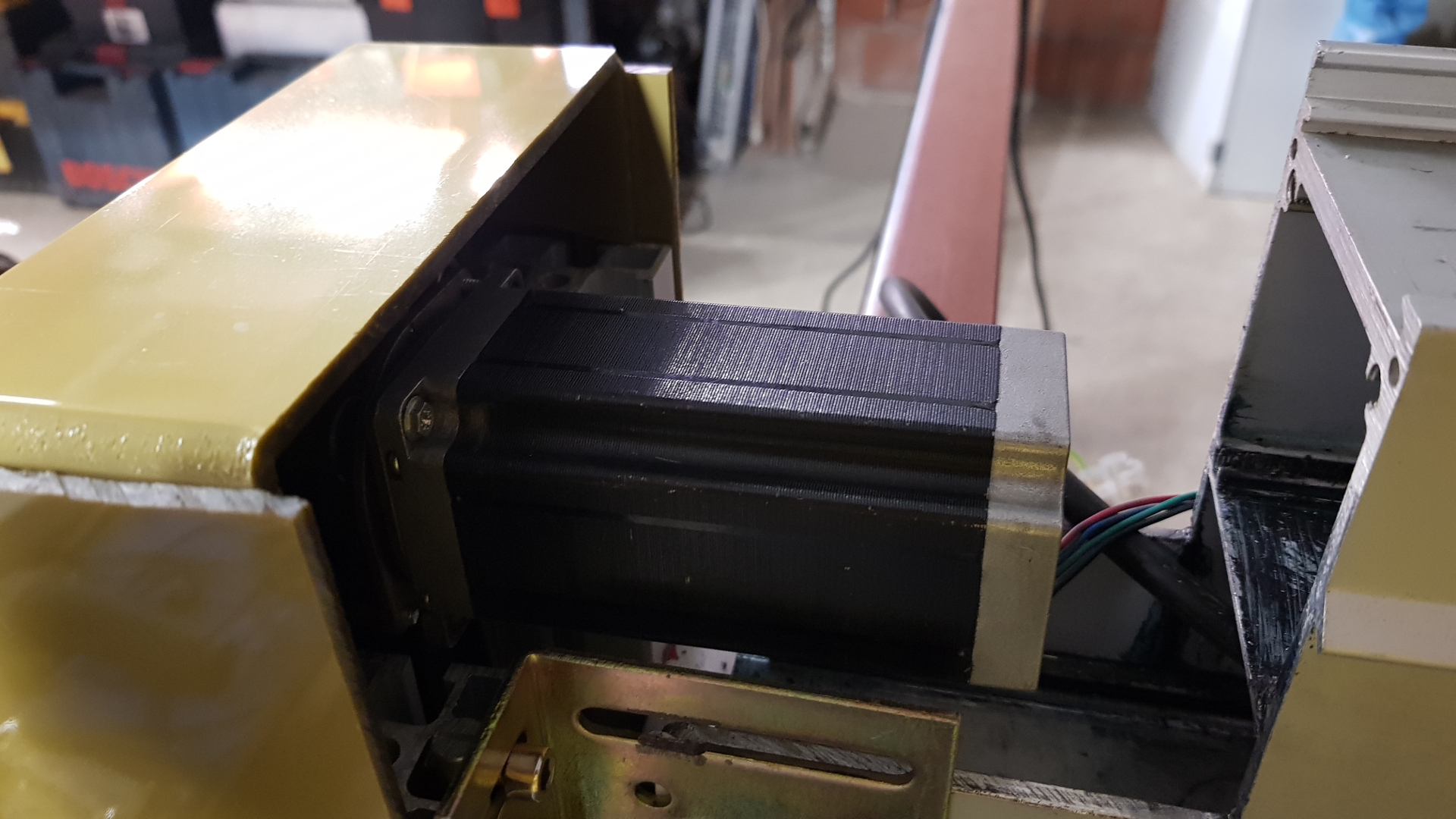

Some more work done while i am waiting for the cable management or energy chain to arrive and the side and front plate to be cut on a cnc. Now, if anyone has an idea what should be written on those sides and front, feel free to chime in. Had a bit of plastic left from the cover of Z axis so i made these covers for the sides:

Also notice the motors are changed, now 3MN Nema 23 at 110mm of length.

Regards,

Tom.

Also notice the motors are changed, now 3MN Nema 23 at 110mm of length.

Regards,

Tom.

Attachments:

The following user(s) said Thank You: Clive S, thefabricator03

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

17 Nov 2019 01:44 #150501

by tommylight

Replied by tommylight on topic 3.5X1.5 Meters cnc plasma cutter

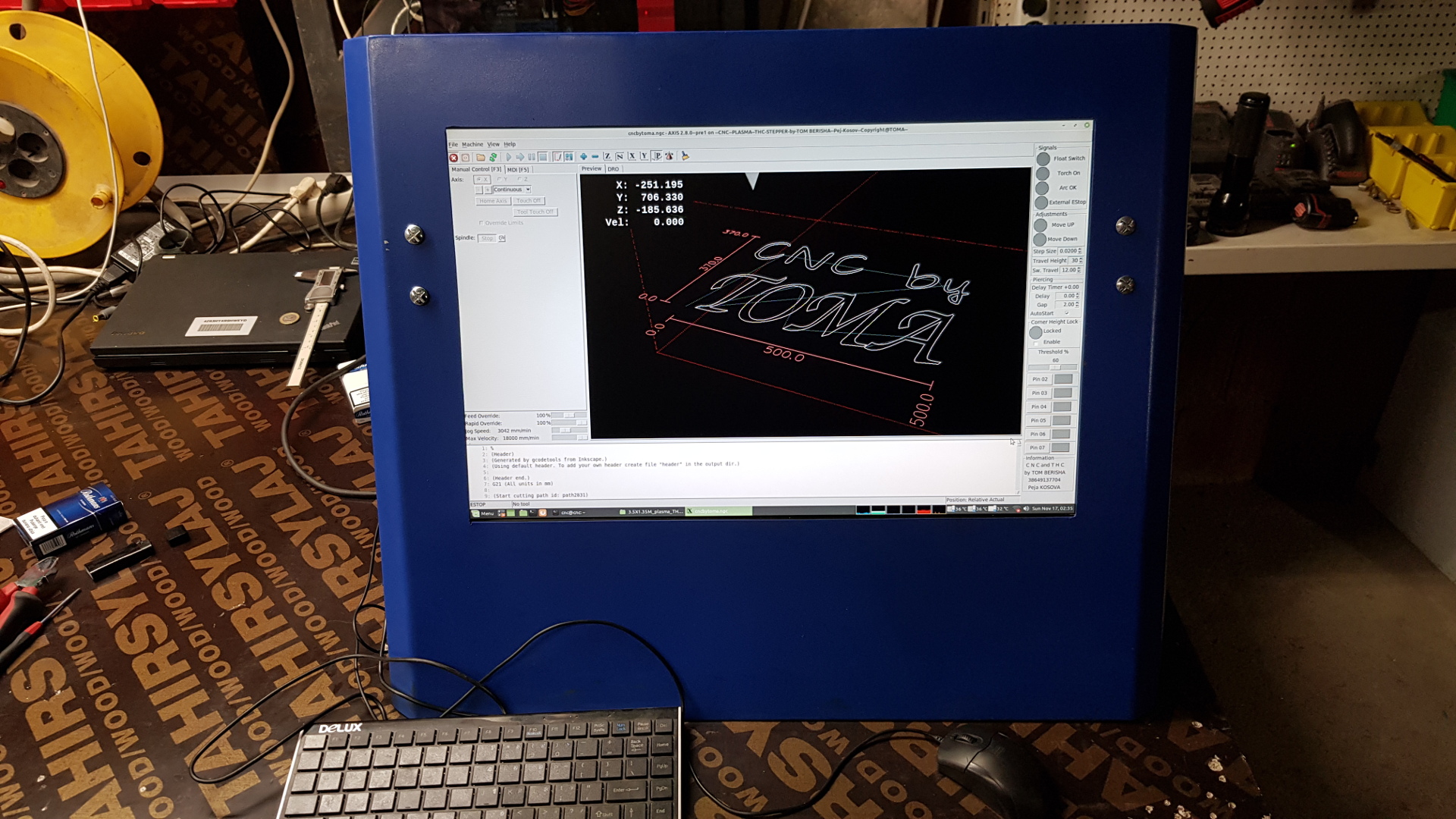

This is the console for the machine, sans the bottom part and a swivelling arm, hopefully tomorrow.

And here is how far down the torch can go, all 280mm of it.

Still waiting on the bloody drag chain, after some failed attempts at ordering it. On Monday i have to visit a guy who shopud have some left, maybe i can score some.

Regards,

Tom.

And here is how far down the torch can go, all 280mm of it.

Still waiting on the bloody drag chain, after some failed attempts at ordering it. On Monday i have to visit a guy who shopud have some left, maybe i can score some.

Regards,

Tom.

Attachments:

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

19 Nov 2019 05:51 #150610

by thefabricator03

Replied by thefabricator03 on topic 3.5X1.5 Meters cnc plasma cutter

Tom,

Do you have any experience using large stepper motors on a large heavy plasma gantry?

If so how did you find their performance?

Do you have any experience using large stepper motors on a large heavy plasma gantry?

If so how did you find their performance?

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.218 seconds