How to cut thick material from edge

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

13 May 2020 08:29 #167625

by tommylight

Jog the torch to the edge, set the offsets, start the cut by pressing F9 or by adding M3 at the top of gcode for that part.

Rinse and repeat .

Replied by tommylight on topic How to cut thick material from edge

Manually, there are to many variables to be able to automate that.The question is how to start cut from the edge not with piercing.

Jog the torch to the edge, set the offsets, start the cut by pressing F9 or by adding M3 at the top of gcode for that part.

Rinse and repeat .

Please Log in or Create an account to join the conversation.

- alexandrub

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 5

13 May 2020 12:41 #167642

by alexandrub

Replied by alexandrub on topic How to cut thick material from edge

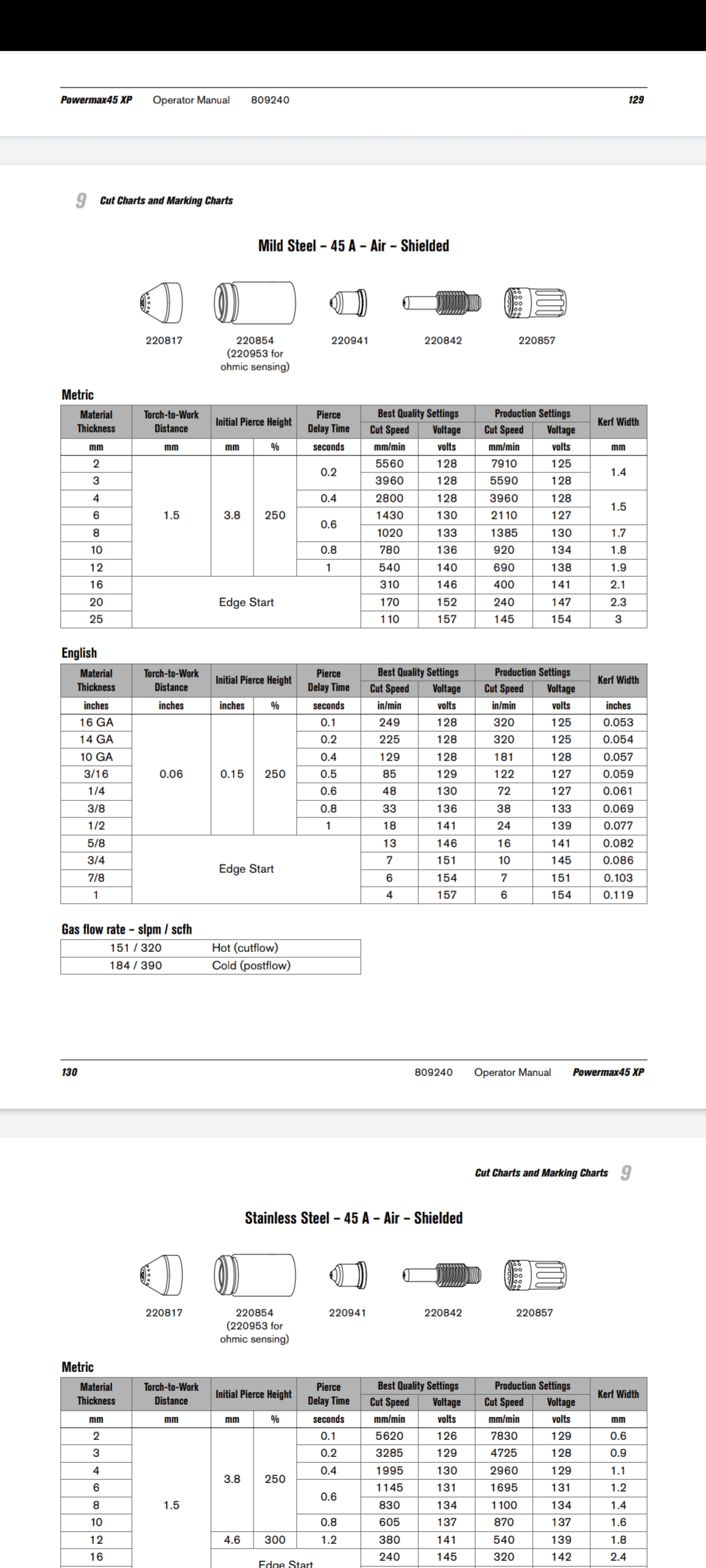

Yeh, we knew what you meant. I had to find your manual. I am surprised they list edge start for material that thick but the proof is in the pudding

Attachments:

Please Log in or Create an account to join the conversation.

- alexandrub

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 5

13 May 2020 12:44 #167643

by alexandrub

Ok, but i do nit want to cut just a straight line. I want to cut an model, and i can put the lead in outside the material but arc ok report that arc is not ok .

.

I do not abuse cutting so thicknes...just some piece.

Replied by alexandrub on topic How to cut thick material from edge

Manually, there are to many variables to be able to automate that.The question is how to start cut from the edge not with piercing.

Jog the torch to the edge, set the offsets, start the cut by pressing F9 or by adding M3 at the top of gcode for that part.

Rinse and repeat .

Ok, but i do nit want to cut just a straight line. I want to cut an model, and i can put the lead in outside the material but arc ok report that arc is not ok

I do not abuse cutting so thicknes...just some piece.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

13 May 2020 13:14 #167646

by tommylight

Replied by tommylight on topic How to cut thick material from edge

Set the "maximum velocity" slider to the same as cut speed, press f9, then run from here from the beginning of the gcocde.

In this case, remove the M3 in gcode.

You can cut any shape or form as long as you start each one separately.

In this case, remove the M3 in gcode.

You can cut any shape or form as long as you start each one separately.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

13 May 2020 13:45 #167648

by Clive S

Could you not just butt up another piece of steel next to your part and the start the lead in from off the part?

Replied by Clive S on topic How to cut thick material from edge

Manually, there are to many variables to be able to automate that.The question is how to start cut from the edge not with piercing.

Jog the torch to the edge, set the offsets, start the cut by pressing F9 or by adding M3 at the top of gcode for that part.

Rinse and repeat .

Ok, but i do nit want to cut just a straight line. I want to cut an model, and i can put the lead in outside the material but arc ok report that arc is not ok.

I do not abuse cutting so thicknes...just some piece.

Could you not just butt up another piece of steel next to your part and the start the lead in from off the part?

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

13 May 2020 13:46 #167649

by thefabricator03

Replied by thefabricator03 on topic How to cut thick material from edge

You need to have your torch just on the edge so when it starts cutting it is cutting steel not air, I do this for line cuts to sever sheets by pulsing the torch and the air will slash water from my water tray up. I then jog the machine until I find the perfect spot to start the cut.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

13 May 2020 15:23 #167652

by tommylight

Centring the torch at the edge is easy, you just have to know from what side to look at it.

Replied by tommylight on topic How to cut thick material from edge

Even having the torch about a millimetre or two inside the material works ok, it just sprays sideways a lot.You need to have your torch just on the edge so when it starts cutting it is cutting steel not air, .........

Centring the torch at the edge is easy, you just have to know from what side to look at it.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

14 May 2020 01:18 #167693

by thefabricator03

Yeah that is true. It just comes down to the operators experience with the machine. Starting near the edge even if in a couple of mm sure makes starting a lot easier.

All this talk of trying out the book max specs of the machine has me thinking of trying out 60mm plate, just need to find a use for it.

Replied by thefabricator03 on topic How to cut thick material from edge

Even having the torch about a millimetre or two inside the material works ok, it just sprays sideways a lot.

Centring the torch at the edge is easy, you just have to know from what side to look at it.

Yeah that is true. It just comes down to the operators experience with the machine. Starting near the edge even if in a couple of mm sure makes starting a lot easier.

All this talk of trying out the book max specs of the machine has me thinking of trying out 60mm plate, just need to find a use for it.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

14 May 2020 10:46 #167720

by tommylight

I need some parts for a small mill, but i can not find anything thicker than 20mm here. But i did find 80mm round one, nut i do not need that.

Replied by tommylight on topic How to cut thick material from edge

I have some ides, but i am to far from everything !All this talk of trying out the book max specs of the machine has me thinking of trying out 60mm plate, just need to find a use for it.

I need some parts for a small mill, but i can not find anything thicker than 20mm here. But i did find 80mm round one, nut i do not need that.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

14 May 2020 11:13 #167722

by rodw

Replied by rodw on topic How to cut thick material from edge

Well I do know some guys pre-pierce with magnetic drill where they need an inside cut

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.154 seconds