Voltage divider for Mesa THCAD-10?

- mal136

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 1

18 May 2021 19:46 - 18 May 2021 19:49 #209386

by mal136

Voltage divider for Mesa THCAD-10? was created by mal136

Hello, somewhat-New to LinuxCNC & this MESA hardware, I've previously had GRBL setup and worked okay, i needed the THC so switched to LinuxCNC to improve the machine overall. I've spent countless hours trying to figure this out and have read this a million times over,( linuxcnc.org/docs/2.8/html/plasma/plasma-cnc-primer.html ), and i am still not confident in what to do here:

Here's my main issue, i cannot find any reliable information that clearly states how to create this voltage divider for a MESA THCAD-10, I am aware how a voltage divider works but want to ensure i am doing this properly because i am aware the power levels here can be lethal/dangerous! ( If I remember correctly, I was told previously by Mesa to use with 2 mega ohm resistors in series INSIDE the machine & heat-shrink this, the 1/4watt resistors are not enough for 220-250volts, but this would mean the voltage divider would output like 100+ volts , which my THCAD-10 is rated from 0-10volts ? I am so confused about this, I personally believe i need a 50k Ohm and 2K ohm resistor in series, which would keep me in the 0-10volt range, is this correct?

Same question, different wording:

The MESA THCAD-10 has an input from 0-10volts, is 500v tolerant indefinitely. So does this mean my voltage divider must provide a voltage between 0-10volts for it to be useful? ( i would imagine if it exceeds 10volts that it would just max out and not modulate the Z-axis)

Also, what resistor setup would be adequate for this setup? 1/4watt, 1/2 watt, 1 watt? and what values?

Here is my setup:

Plasma cutter(Cut 50 w/ blowback torch, Not a HF start, works great)

www.amazon.com/Plasma-Voltage-Cutting-Ma...rtable/dp/B083NPBQ7D

Motion control Hardware: MESA 7I96 & MESA THCAD-10

Thank you in advanced to whoever replies!

Here's my main issue, i cannot find any reliable information that clearly states how to create this voltage divider for a MESA THCAD-10, I am aware how a voltage divider works but want to ensure i am doing this properly because i am aware the power levels here can be lethal/dangerous! ( If I remember correctly, I was told previously by Mesa to use with 2 mega ohm resistors in series INSIDE the machine & heat-shrink this, the 1/4watt resistors are not enough for 220-250volts, but this would mean the voltage divider would output like 100+ volts , which my THCAD-10 is rated from 0-10volts ? I am so confused about this, I personally believe i need a 50k Ohm and 2K ohm resistor in series, which would keep me in the 0-10volt range, is this correct?

Same question, different wording:

The MESA THCAD-10 has an input from 0-10volts, is 500v tolerant indefinitely. So does this mean my voltage divider must provide a voltage between 0-10volts for it to be useful? ( i would imagine if it exceeds 10volts that it would just max out and not modulate the Z-axis)

Also, what resistor setup would be adequate for this setup? 1/4watt, 1/2 watt, 1 watt? and what values?

Here is my setup:

Plasma cutter(Cut 50 w/ blowback torch, Not a HF start, works great)

www.amazon.com/Plasma-Voltage-Cutting-Ma...rtable/dp/B083NPBQ7D

Motion control Hardware: MESA 7I96 & MESA THCAD-10

Thank you in advanced to whoever replies!

Last edit: 18 May 2021 19:49 by mal136.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 10795

- Thank you received: 3556

18 May 2021 20:01 #209388

by rodw

Replied by rodw on topic Voltage divider for Mesa THCAD-10?

Everything you need to know is in the THCAD manual. The resistor wattage does not really matter. I would maybe use 1 W but I have used 1/2 W and 1/4 W.

1. Pick a full scale reading. Suggest 200 volts but 300 volts is OK.

2. Calculate the resistance required to achieve this, place half of that on each side of the THCAD inputs

3. If there is enough room in the case to mount the THCAD, put it there otherwise mount in a metal case attached to the machine but place the resistors inside for safety.

4.Run a shielded cable between the plasma cutter and the controller. 6 core minimum

5. Send 5 volts from the Mesa encoder pins to the THCAD10

6 bring the frequency back along the cable and attach to the encoder inputs

7. Use another pair of wires in that cable for the torch on signal.

I'd probably try and add a new connector to the plasma cutter for these wires and connect the torch on signal internally to make a nice neat finish. Then leave the torch connector unconnected while its being used under CNC control

1. Pick a full scale reading. Suggest 200 volts but 300 volts is OK.

2. Calculate the resistance required to achieve this, place half of that on each side of the THCAD inputs

3. If there is enough room in the case to mount the THCAD, put it there otherwise mount in a metal case attached to the machine but place the resistors inside for safety.

4.Run a shielded cable between the plasma cutter and the controller. 6 core minimum

5. Send 5 volts from the Mesa encoder pins to the THCAD10

6 bring the frequency back along the cable and attach to the encoder inputs

7. Use another pair of wires in that cable for the torch on signal.

I'd probably try and add a new connector to the plasma cutter for these wires and connect the torch on signal internally to make a nice neat finish. Then leave the torch connector unconnected while its being used under CNC control

The following user(s) said Thank You: mal136

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 19479

- Thank you received: 6532

18 May 2021 20:20 #209394

by tommylight

Replied by tommylight on topic Voltage divider for Mesa THCAD-10?

As luck would have it, done this today (and lots of times before) ans it is that simple, just add 2 of the 1MOhm resistors to the inside of the plasma cutter ( BTW, what plasma? ) one on the positive and one on the negative side of things.

It is possible to use a single 2 MOhm resistor only on one of the leads, but that implies isolating and making sure the other lead does not touch anything on the way to the THCAD. Standard resistor value would be 2.2 MOhm, does not matter much it will work.

And your math for the divider is correct, but the divider would be 1:52 since 50+2 KOhm, again does not matter much.

The thing is, THCAD has it's own set input resistance so it does not need a classic voltage divider, it is part of the divider.

It is possible to use a single 2 MOhm resistor only on one of the leads, but that implies isolating and making sure the other lead does not touch anything on the way to the THCAD. Standard resistor value would be 2.2 MOhm, does not matter much it will work.

And your math for the divider is correct, but the divider would be 1:52 since 50+2 KOhm, again does not matter much.

The thing is, THCAD has it's own set input resistance so it does not need a classic voltage divider, it is part of the divider.

The following user(s) said Thank You: rodw, mal136

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17967

- Thank you received: 4826

18 May 2021 21:01 #209406

by PCW

Replied by PCW on topic Voltage divider for Mesa THCAD-10?

You can also consider the THCAD as a current operated device

a THCAD10 or 300 is 100 uA full scale, a THCAD5 is 50 uA full scale.

a THCAD10 or 300 is 100 uA full scale, a THCAD5 is 50 uA full scale.

The following user(s) said Thank You: mal136

Please Log in or Create an account to join the conversation.

- mal136

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 1

20 May 2021 01:49 - 20 May 2021 01:50 #209596

by mal136

Replied by mal136 on topic Voltage divider for Mesa THCAD-10?

Thank you to all who replied ! I greatly appreciate it.

The more I read info on the web, the more i get confused. I have been using Arduino, coding and building CNC's & 3D printers using that stuff for 5+years, i'm partially competent with this stuff. This LinuxCNC stuff & Mesa is throwing me way off. It is more difficult (it seems) to find any reliable & rock-solid information on what to do step-by-step. It makes me nervous that I could damage $200 worth of boards if not setup properly.

I have to dive so deep through these forums to get any information and it seems to just confuse me even more. i'm really worried i won't be able to get this up and running.

I've read the Mesa THCAD & 7I96 manuals & linuxCNC primer, all great information but I am still having trouble grasping the THCAD-10 and how going over 10volts on the inputs is going to yield the 0-10volt range that it accepts? Does the "10volts" label not mean this?

Am I correct that once the voltage input to the THCAD-10 goes over 10volts that the signal is no longer useful in modulating the THC?

Also i see that 7i96 accepts 36volts inputs, can i use 36volts for my home & limit switches? ( i see everyone using 24v+, not sure if 36v+ is a no-go?)

"11 isolated inputs provided for general control use including limit switch and control

panel inputs. Inputs operate with 4V to 36V DC and can have a positive or negative

common for sourcing or sinking input applications. Six 36V 2A isolated outputs allow

sinking, sourcing combinations of both."

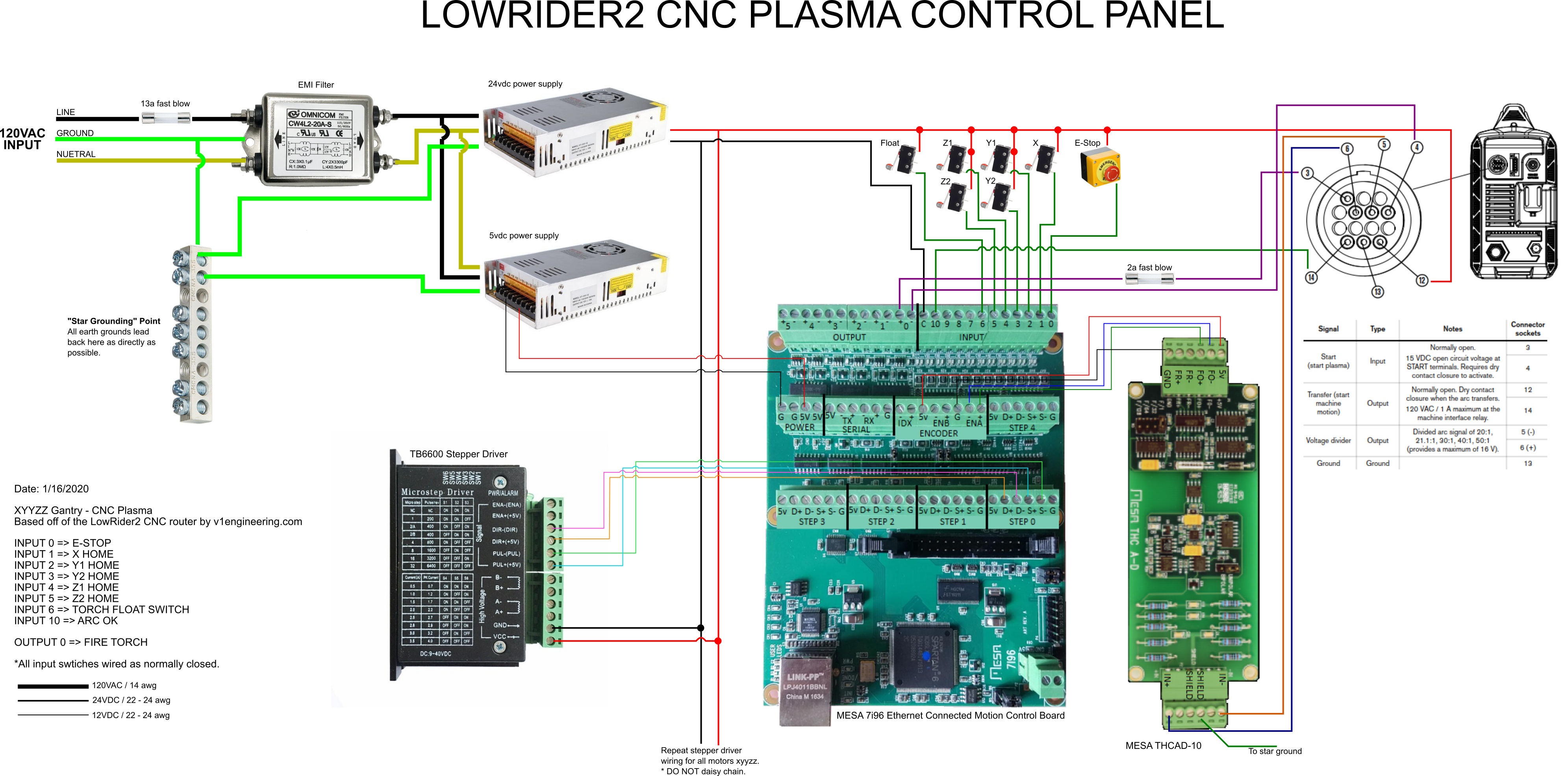

Here is the diagram i've found & am going off of so far:

(also attached in case link break)

Is this a proper diagram? if not, Can anyone provide or point me to a reliable diagram to go off of? ( i really dont want to be that guy , but i'm struggling here & this would quickly solve my lack-of-knowledge here)

All reference information:

My current Hardware: 7i96, THCAD-10, CUT50L(blow-back plasma cutter, non-HF start & i (think) i'm planning on building a voltage divider in the machine and put the THCAD-10 in the Plasma casing(plenty of room by the way) ) www.amazon.com/Plasma-Voltage-Cutting-Ma...rtable/dp/B083NPBQ7D

(Links for other's:)

THCAD:

www.mesanet.com/pdf/analog/thcadman.pdf

7i96:

www.mesanet.com/pdf/parallel/7i96man.pdf

LinuxCNC Plasma Primer:

(linuxcnc.org/docs/2.8/html/plasma/plasma...#_float_switch_input)

The more I read info on the web, the more i get confused. I have been using Arduino, coding and building CNC's & 3D printers using that stuff for 5+years, i'm partially competent with this stuff. This LinuxCNC stuff & Mesa is throwing me way off. It is more difficult (it seems) to find any reliable & rock-solid information on what to do step-by-step. It makes me nervous that I could damage $200 worth of boards if not setup properly.

I have to dive so deep through these forums to get any information and it seems to just confuse me even more. i'm really worried i won't be able to get this up and running.

I've read the Mesa THCAD & 7I96 manuals & linuxCNC primer, all great information but I am still having trouble grasping the THCAD-10 and how going over 10volts on the inputs is going to yield the 0-10volt range that it accepts? Does the "10volts" label not mean this?

Am I correct that once the voltage input to the THCAD-10 goes over 10volts that the signal is no longer useful in modulating the THC?

Also i see that 7i96 accepts 36volts inputs, can i use 36volts for my home & limit switches? ( i see everyone using 24v+, not sure if 36v+ is a no-go?)

"11 isolated inputs provided for general control use including limit switch and control

panel inputs. Inputs operate with 4V to 36V DC and can have a positive or negative

common for sourcing or sinking input applications. Six 36V 2A isolated outputs allow

sinking, sourcing combinations of both."

Here is the diagram i've found & am going off of so far:

(also attached in case link break)

Is this a proper diagram? if not, Can anyone provide or point me to a reliable diagram to go off of? ( i really dont want to be that guy , but i'm struggling here & this would quickly solve my lack-of-knowledge here)

All reference information:

My current Hardware: 7i96, THCAD-10, CUT50L(blow-back plasma cutter, non-HF start & i (think) i'm planning on building a voltage divider in the machine and put the THCAD-10 in the Plasma casing(plenty of room by the way) ) www.amazon.com/Plasma-Voltage-Cutting-Ma...rtable/dp/B083NPBQ7D

(Links for other's:)

THCAD:

www.mesanet.com/pdf/analog/thcadman.pdf

7i96:

www.mesanet.com/pdf/parallel/7i96man.pdf

LinuxCNC Plasma Primer:

(linuxcnc.org/docs/2.8/html/plasma/plasma...#_float_switch_input)

Last edit: 20 May 2021 01:50 by mal136. Reason: added image attachment

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 10795

- Thank you received: 3556

20 May 2021 02:03 #209601

by rodw

Replied by rodw on topic Voltage divider for Mesa THCAD-10?

Just reiterating you DO NOT NEED a voltage divider. All you need is to use a scaling resistor as outlined in the THCAD manual. This will scale your desired full scale reading to the 0-10 volt scale of the THCAD10. The THCAD can handle overvoltage of 500 volts on the 0-10 volt inputs without being damaged.

There are only two sources of info you can trust. The LinuxCNC document page for the LCNC version you are using and the Mesa Manuals. Use anything else at your own risk. There is no guarantee it is correct or still current.

24 volts is normal for field power and industrial logic signals in general. You don't really want to be running at the maximum for reliability.

There are only two sources of info you can trust. The LinuxCNC document page for the LCNC version you are using and the Mesa Manuals. Use anything else at your own risk. There is no guarantee it is correct or still current.

24 volts is normal for field power and industrial logic signals in general. You don't really want to be running at the maximum for reliability.

The following user(s) said Thank You: mal136, CarterKraft

Please Log in or Create an account to join the conversation.

- mal136

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 1

20 May 2021 02:37 #209602

by mal136

Replied by mal136 on topic Voltage divider for Mesa THCAD-10?

I am an idiot, I was so caught up in my worry i missed that completely. So sorry for my lack of brain function here haha. This cleared up 99% of my questions. You sir are my hero. Thank you so so very much!

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 205

- Thank you received: 46

20 May 2021 08:33 #209626

by RNJFAB

Replied by RNJFAB on topic Voltage divider for Mesa THCAD-10?

AS RODW SAID, you don't need a voltage divider, you just need to limit the flow from the machine to the THCAD10.

I had a cut 50 running on my system using 1M (5w I think) resistor on each line back to the thcad. www.jaycar.com.au/search?text=1m+1+watt&...e8-9e55-e1bddca5b2c9

I did this inside the case so the shielded pair of wires coming out were good to go.

I had a cut 50 running on my system using 1M (5w I think) resistor on each line back to the thcad. www.jaycar.com.au/search?text=1m+1+watt&...e8-9e55-e1bddca5b2c9

I did this inside the case so the shielded pair of wires coming out were good to go.

The following user(s) said Thank You: mal136

Please Log in or Create an account to join the conversation.

- AgentWD40

-

- Offline

- Platinum Member

-

Less

More

- Posts: 334

- Thank you received: 92

20 May 2021 14:13 - 20 May 2021 14:17 #209650

by AgentWD40

That's my diagram!

FULL DISCLOSURE: I'm a tinkerer with zero electronic/electrical training. As such I drew that diagram and posted it here on the forum so I could get feedback from the community, not so much to guide others (though I'm happy to help!... if it works). I did use that diagram in my build except I didn't use any fuses (yet) and I used a mechanical relay to switch the hypertherm torch on/off. So far my machine works fine except I'm recently experiencing arkOk issues for which there are competing solutions on these forums, one solution is software based debouncing, the other is hardware based. Life has gotten in the way and I haven't had time to tackle this issue yet.

Replied by AgentWD40 on topic Voltage divider for Mesa THCAD-10?

Here is the diagram i've found & am going off of so far:

Is this a proper diagram? if not, Can anyone provide or point me to a reliable diagram to go off of? ( i really dont want to be that guy , but i'm struggling here & this would quickly solve my lack-of-knowledge here)

That's my diagram!

FULL DISCLOSURE: I'm a tinkerer with zero electronic/electrical training. As such I drew that diagram and posted it here on the forum so I could get feedback from the community, not so much to guide others (though I'm happy to help!... if it works). I did use that diagram in my build except I didn't use any fuses (yet) and I used a mechanical relay to switch the hypertherm torch on/off. So far my machine works fine except I'm recently experiencing arkOk issues for which there are competing solutions on these forums, one solution is software based debouncing, the other is hardware based. Life has gotten in the way and I haven't had time to tackle this issue yet.

Last edit: 20 May 2021 14:17 by AgentWD40.

The following user(s) said Thank You: mal136

Please Log in or Create an account to join the conversation.

- mal136

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 1

20 May 2021 19:32 #209681

by mal136

Replied by mal136 on topic Voltage divider for Mesa THCAD-10?

Haha nice, small world here!. I appreciate you making it & staying on the forum to help noobs like me.

I have most everything figured out so far, going to get it all wired up today & start getting LinuxCNC setup & hopefully do some test cuts tonight. I can't wait.

Thank you again to everyone , greatly appreciate it

I have most everything figured out so far, going to get it all wired up today & start getting LinuxCNC setup & hopefully do some test cuts tonight. I can't wait.

Thank you again to everyone , greatly appreciate it

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.074 seconds