Black Friday Deal got me :)

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

07 Jan 2025 14:07 #318301

by machinedude

Replied by machinedude on topic Black Friday Deal got me :)

yep, already had that thought with the 4-jaw chuck route. the pneumatic idea will require different jaws for different material size but those could be made as well. that's the easy part. figuring out how to put it all together and not break the bank in the process is the hard part  any kind of hollow body design for something fancy gets expensive quick the bigger you get.

any kind of hollow body design for something fancy gets expensive quick the bigger you get.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

10 Jan 2025 19:56 - 10 Jan 2025 19:58 #318659

by machinedude

Replied by machinedude on topic Black Friday Deal got me :)

That manual self-centering 4 jaw chuck came yesterday, and that brand seems pretty well made and works really well.

i have some material ordered and coming for a attempt at a rotary union, the seals should be here today, i hope this material is not under sized or i will have issues. for whatever reason thick-walled tube in this size range is expensive and i only had one supplier that i have used that was fair on price, but sizes were limited. i checked on bar stock prices and that was even more expensive yet it's amazing how you get screwed so bad on prices for small orders.

it's amazing how you get screwed so bad on prices for small orders.

these unions are hard to make on the cheap. i did see one import that had 120 mm bore but was around $400 each. what i am trying is 140 mm bore. not big enough for a 4" square tube so it is what it is i guess. if i can make these i can make 2 of them for around half the price of one of the smaller imports.

i hope i can make it work would be a neat build and if nothing else i am eager to try it at least. nothing ventured nothing gained

would be a neat build and if nothing else i am eager to try it at least. nothing ventured nothing gained

i have some material ordered and coming for a attempt at a rotary union, the seals should be here today, i hope this material is not under sized or i will have issues. for whatever reason thick-walled tube in this size range is expensive and i only had one supplier that i have used that was fair on price, but sizes were limited. i checked on bar stock prices and that was even more expensive yet

these unions are hard to make on the cheap. i did see one import that had 120 mm bore but was around $400 each. what i am trying is 140 mm bore. not big enough for a 4" square tube so it is what it is i guess. if i can make these i can make 2 of them for around half the price of one of the smaller imports.

i hope i can make it work

Last edit: 10 Jan 2025 19:58 by machinedude.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

21 Jan 2025 22:15 #319597

by machinedude

Replied by machinedude on topic Black Friday Deal got me :)

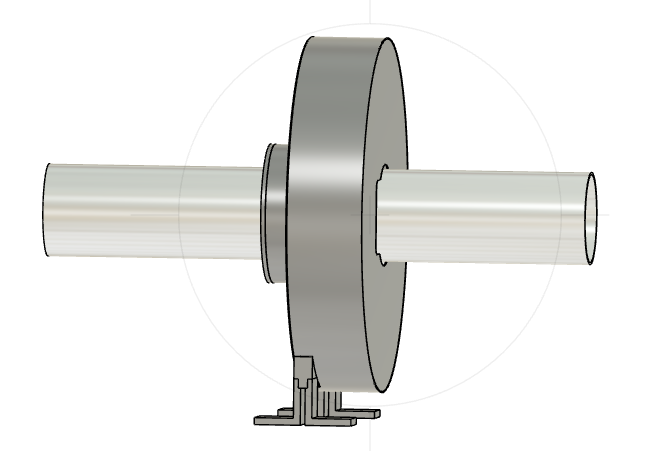

the deeper i get into this the more i realize how ambitious this project really is  one thing i did notice was i need to add some travel to my z axis to do everything i want it to do. these self-centering pneumatic chucks are turning out to be pretty big once you cover them with some sort of guard. the rotary end is going to be much more involved if this works out for me. as far as the moving parts go things seem to work really well so far. the thing that could break this is the rotary union if it does not seal well.

one thing i did notice was i need to add some travel to my z axis to do everything i want it to do. these self-centering pneumatic chucks are turning out to be pretty big once you cover them with some sort of guard. the rotary end is going to be much more involved if this works out for me. as far as the moving parts go things seem to work really well so far. the thing that could break this is the rotary union if it does not seal well.

this build is like building 3 machines if everything works out as planned these end up being almost 21" tall and a little over 19" in diameter and 6 1/4 "wide i added a 5" round tube which will be the max on round tube. the guards should be a treat to make the plan is to laser cut some flat sheet and either weld them together or use a special solder rod made for aluminum. welding aluminum is not something i enjoy or am very good at

these end up being almost 21" tall and a little over 19" in diameter and 6 1/4 "wide i added a 5" round tube which will be the max on round tube. the guards should be a treat to make the plan is to laser cut some flat sheet and either weld them together or use a special solder rod made for aluminum. welding aluminum is not something i enjoy or am very good at

but anyways here is a screen grab of my model to give you and idea of what this will look like if it works

this build is like building 3 machines if everything works out as planned

but anyways here is a screen grab of my model to give you and idea of what this will look like if it works

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11545

- Thank you received: 3871

22 Jan 2025 00:21 #319604

by rodw

Replied by rodw on topic Black Friday Deal got me :)

Travis MItchell has an excellent series on buidling a rotary tube cutter for a laser head for circular, square and rectangular tube.

You should review his chuck design befor going to far into this. The material is held between 2 seperate self centring roller assemblies so it can move in and out while driven by a powered chuck at the other end on a tailstock on the Y axis. I don't get why he powers two chucks. I think only one powered chuck is required.

You should review his chuck design befor going to far into this. The material is held between 2 seperate self centring roller assemblies so it can move in and out while driven by a powered chuck at the other end on a tailstock on the Y axis. I don't get why he powers two chucks. I think only one powered chuck is required.

The following user(s) said Thank You: Daan96

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11545

- Thank you received: 3871

22 Jan 2025 00:24 #319606

by rodw

Replied by rodw on topic Black Friday Deal got me :)

I think converting this to a table addon, I would extend th x axis past the table edge and suspend the chuck below it and just have a lazy unpowered chuck at the end of the table aligned to the roller chuck. It would be the roller chuck moving then.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

22 Jan 2025 01:59 #319611

by machinedude

Replied by machinedude on topic Black Friday Deal got me :)

i seen his video it's a pretty nice build but it is a manual self-centering if i remember right. the idea is to have the overhang so you can have both the flat table for larger stuff and the rotary off to one side.

what would be different about what i want to do is have the automated clamping and a second liner axis as a bar feeder and drive the rotary from a second in the rear in line with the fixed end. the fixed end is basically a steady rest with automated clamping system to hold the place while the other can be released to move back and grab another bite on the material and keep feeding material if you want to cut something long,

you basically have infinite travel on a small footprint machine.

what would be different about what i want to do is have the automated clamping and a second liner axis as a bar feeder and drive the rotary from a second in the rear in line with the fixed end. the fixed end is basically a steady rest with automated clamping system to hold the place while the other can be released to move back and grab another bite on the material and keep feeding material if you want to cut something long,

you basically have infinite travel on a small footprint machine.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

22 Jan 2025 19:09 #319659

by machinedude

Replied by machinedude on topic Black Friday Deal got me :)

One other thing about a supported rotary set up is if you have a stock width that will fit the bore of your set up you can reduce you cutting distance compared to cutting from plate. when you look at things like duty cycle that's a big plus when your cutting @ 60% duty. On top you don't have to wear your slats down either, so you reduce your operating cost. so, it makes sense on small parts to keep this in mind.

when you get to a point where you are processing a lot of sheets the skeletons of the sheet add up to quite a bit of wasted material. this is just something you notice if you are around it all the time. i know time is money and that's why it happens but looking for savings can't be forgotten about at the same time.

when you get to a point where you are processing a lot of sheets the skeletons of the sheet add up to quite a bit of wasted material. this is just something you notice if you are around it all the time. i know time is money and that's why it happens but looking for savings can't be forgotten about at the same time.

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

27 Jan 2025 08:20 #319938

by machinedude

Replied by machinedude on topic Black Friday Deal got me :)

well i hit my first snag already  i picked up 2 air cylinders with the intention of picking a few more up if the plan works out. turns out they no longer have the cylinders i got before in stock now. so i had to come up with a plan B

i picked up 2 air cylinders with the intention of picking a few more up if the plan works out. turns out they no longer have the cylinders i got before in stock now. so i had to come up with a plan B  so i found some on AliExpress but have to wait. I guess the silver lining would be i now have a better match for this project now. i should be able to make things smaller as a result.

so i found some on AliExpress but have to wait. I guess the silver lining would be i now have a better match for this project now. i should be able to make things smaller as a result.

always something it seems

always something it seems

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

10 Feb 2025 22:37 #321190

by machinedude

Replied by machinedude on topic Black Friday Deal got me :)

Something like 3 weekends later and the rotational parts move as they should. I got lucky with my material choices trying to keep things cheap. I ended up with about .005 to spare on the surfaces that mater and ended up with some mismatched surfaces just from the stock not being round. I got lucky this time. now if i can get it to seal in the right places and direct the air in the right places I'm in business  the rest is downhill on this on this side. the other end is more complicated yet

the rest is downhill on this on this side. the other end is more complicated yet

Attachments:

The following user(s) said Thank You: tommylight, Daan96

Please Log in or Create an account to join the conversation.

- machinedude

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

17 Feb 2025 20:31 #321869

by machinedude

Replied by machinedude on topic Black Friday Deal got me :)

well, it seals at least. with no pressure it spins pretty nice, but my first pressure test tells me once you add pressure it gets tighter to spin. now i have two air zones by design and i am glad i did not add more to get fancy. once i add a solenoid vale and control the air flow i will only have one zone under pressure at a time and i hope the helps with the spinning. i would be afraid to try and cut the glands any deeper the shaft already pulls itself through the body with gravity when put together. i have to do more testing to see where i am at unfortunately.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.098 seconds